Automatic four-color twelve-station complex curved surface digital rotation printing machine

A 12-station, complex curved surface technology, applied in the field of automatic four-color 12-station complex curved surface digital rotary printing press, can solve the problems of unstable printing quality and slow printing speed, and achieve short digital printing cycle, digital printing and other problems. High printing efficiency and satisfying color effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

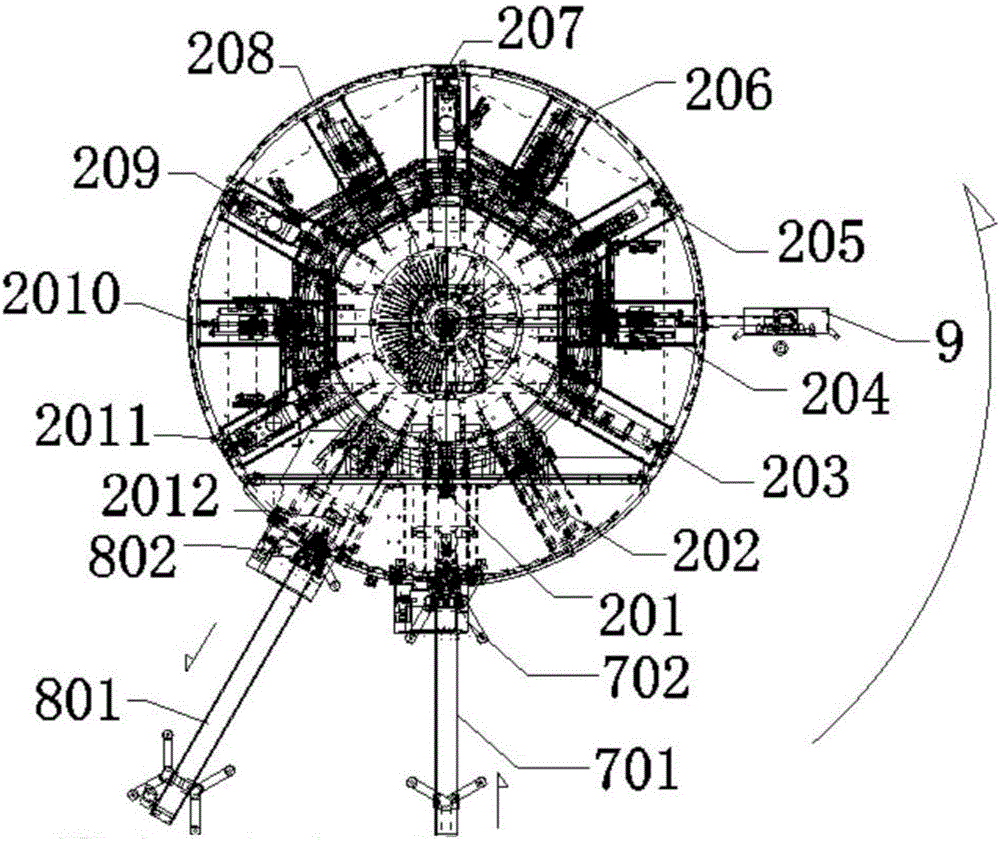

[0044] refer to Figure 7 , digital printing of elliptical bottles: the manipulator at the upper material level clamps the elliptical bottle to be digitally printed from the upper material level to the flame treatment position on the outer surface, and the touch firmware of the manipulator is embedded in the workpiece tooling position to clamp the cylinder assembly Inside the touch switch, the tooling position clamps the cylinder assembly and rotates the oval bottle to be digitally printed for surface flame treatment, and then transfers to the product positioning position to start positioning the oval bottle. After the positioning is completed, transfer to the first digital printing At this time, the rotation axis M1 of the digital printing assembly starts and begins to descend vertically until it approaches the outer surface of the oval bottle side. At the same time, the rotation axes M2 and M3 start synchronously, and the digital printing head passes the ink through the eight...

Embodiment example 2

[0046] refer to Figure 8 , digital printing of special-shaped bottles: the manipulator at the loading level clamps the special-shaped bottle to be digitally printed from the loading position to the flame treatment position on the outer surface, and the touch firmware of the manipulator is embedded in the product tooling position to clamp the cylinder assembly Inside the touch switch, the tooling position clamps the cylinder assembly and rotates the special-shaped bottle to be digitally printed for surface flame treatment, and then transfers to the product positioning position to start positioning the special-shaped bottle. After the positioning is completed, transfer to the first digital printing At this time, the rotation axis M1 of the digital printing assembly starts and begins to descend vertically until it approaches the surface of the special-shaped bottle. At the same time, the rotation axes M2 and M3 start synchronously. The outer surface of the bottle starts printing...

Embodiment example 3

[0048] refer to Figure 9 , digital printing of spherical products: the manipulator at the loading level clamps the spherical product to be digitally printed and transfers it from the loading level to the flame treatment position on the outer surface, and the touch firmware of the manipulator is embedded in the product tooling position to clamp the cylinder assembly Inside the touch switch, the tooling position clamps the cylinder assembly and rotates the spherical product to be digitally printed for surface flame treatment, and then transfers to the product positioning position to start positioning the spherical product. After the positioning is completed, transfer to the first digital printing At this time, the rotation axis M1 of the digital printing assembly starts and begins to descend vertically until it approaches the outer surface of the spherical product. At the same time, the rotation axes M2 and M3 start synchronously. The outer surface of the spherical product star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com