High-performance combined friction pile structure and construction method

A construction method and technology of friction piles, which are applied in basic structure engineering, sheet pile walls, buildings, etc., can solve the problem of low positioning accuracy of the reinforcement cage of the pile body, difficulty in improving the bearing performance of the soil body at the top of the pile, and post-grouting body on the side of the pile. It is difficult to guarantee the integrity of the material of the pile body, etc., to achieve the effect of improving the accuracy and improving the resistance of the pile side.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

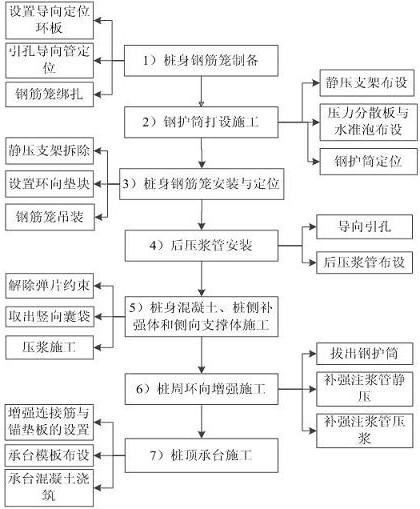

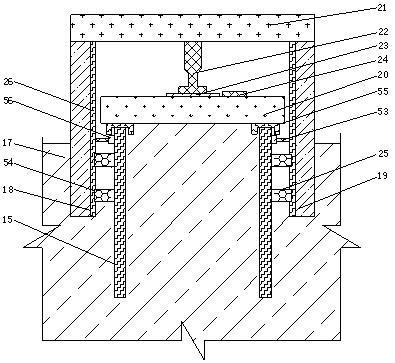

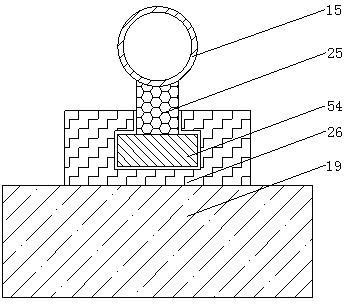

[0060] Embodiment 1: A segmental reinforcement tube 2 is preset in the pile body reinforcement cage 1, and grout seepage slots 48 and rigid elastic pieces 11 are set on the side walls of the segmental reinforcement tube 2; 1 is provided with guide hole guide pipe 7, and the lateral support body 34 can be formed around the pile by means of the rear grouting pipe 31; the steel casing 15 and the circumferential reinforcement are placed in the static pressure mode, and the guide chute 26, Orientation slider 25 and alignment screw 53 control the direction of steel casing 15 and hoop reinforcement; hoop pad 29 is set between pile body reinforcement cage 1 and steel casing 15; ring is set at the top of friction pile 16 To the reinforcing body, by grouting to the reinforcing grouting pipe 38, an annular reinforcing body 39 is formed on the outside of the friction pile 16; Integrity of friction pile 16 and cap concrete 45 .

[0061] Pile body reinforcement cage 1 includes segmental re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com