Electric arc additive manufacturing method

A technology of additive manufacturing and electric arc, which is applied in the direction of manufacturing tools, arc welding equipment, electrode support devices, etc., can solve the problems of complex thin-walled parts and difficult forming of thin-walled metal structures, and achieve a wide range of applications and good forming The effect of quality and process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

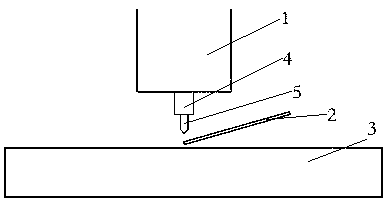

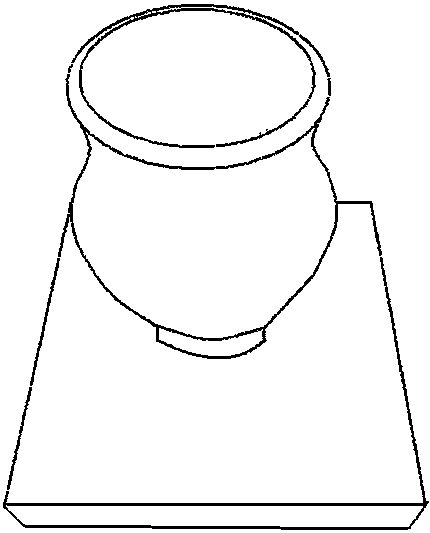

[0025] A kind of electric arc additive manufacturing method, comprises the following steps:

[0026] (1) Select the corresponding heat source type, forming wire material, and substrate material type according to the material requirements of the forming target part;

[0027] (2) Establish the CAD geometric model of the forming target part, extract the STL model, analyze the STL model, slice the STL model, automatically plan the forming path, generate the G code file required for printing, and transmit the G code to the printer ;

[0028] (3) Set the printing parameters, start the printing equipment, set the shape and size of the printed parts, and print metal thin layers layer by layer accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com