3D printing method and system based on cold spraying

A 3D printing and cold spraying technology, applied in the field of 3D physical molding, can solve the problems of low manufacturing efficiency, increased product density, and cumbersomeness, and achieve the effect of improving manufacturing efficiency, high bonding force, and small residual stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The Laval nozzle device involved in the technical solution of the present invention belongs to the prior art. The front half of the nozzle shrinks from large to small to a narrow throat in the middle. The narrow throat then expands from small to large and expands outwards to the bottom of the arrow. The gas in the arrow body flows into the front half of the nozzle under high pressure, and escapes from the rear half after passing through the narrow throat. This structure can change the speed of the airflow due to the change of the nozzle cross-sectional area, so that the airflow can be accelerated from subsonic to sonic, and then accelerated to supersonic. Therefore, people call this horn-shaped nozzle a transonic nozzle. Since it was invented by the Swedish Laval, it is also called "Laval nozzle".

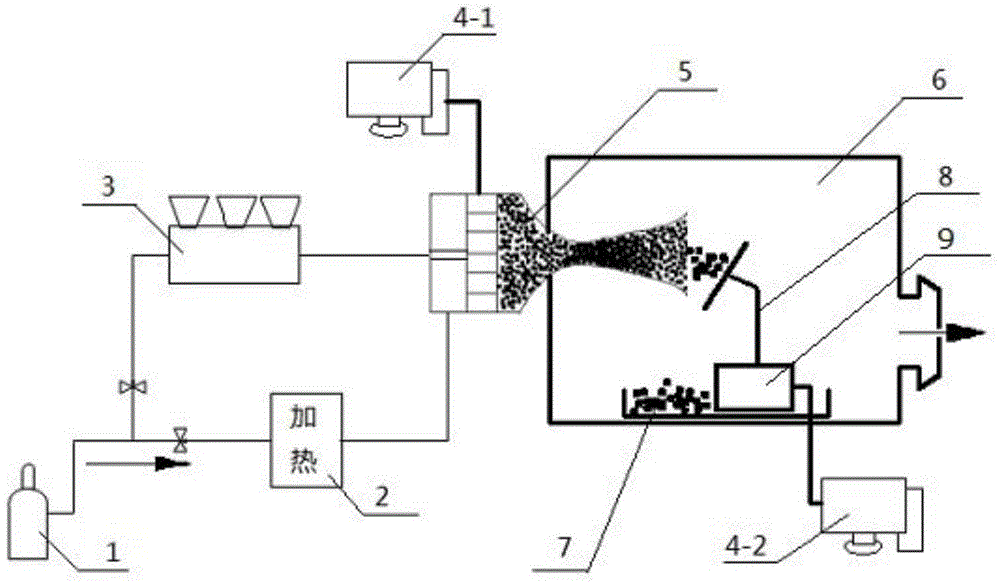

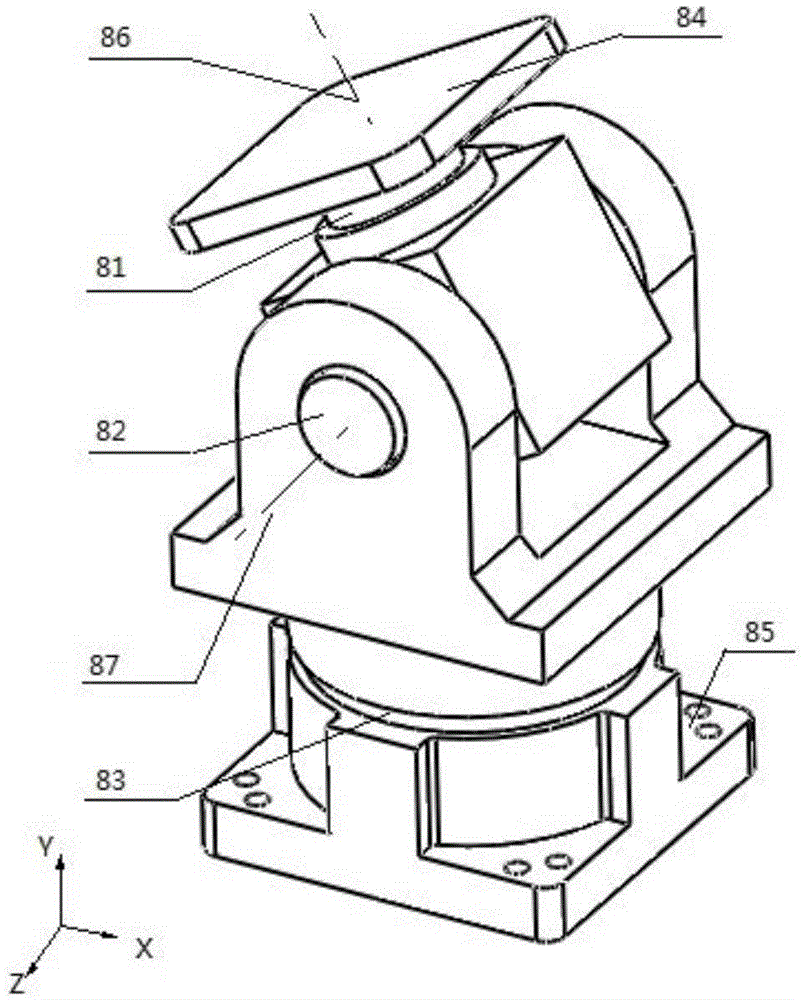

[0032] This 3D printing system mainly includes 9 parts, such as figure 1 Shown is a schematic diagram of the composition of the system, such as figure 2 Shown is a sch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com