Automatic ironing equipment

An ironing equipment and automatic technology, applied in ironing machines, washing devices, textiles and papermaking, etc., can solve problems such as inability to achieve ironing effects, inconsistent ironing effects, and liberation of people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

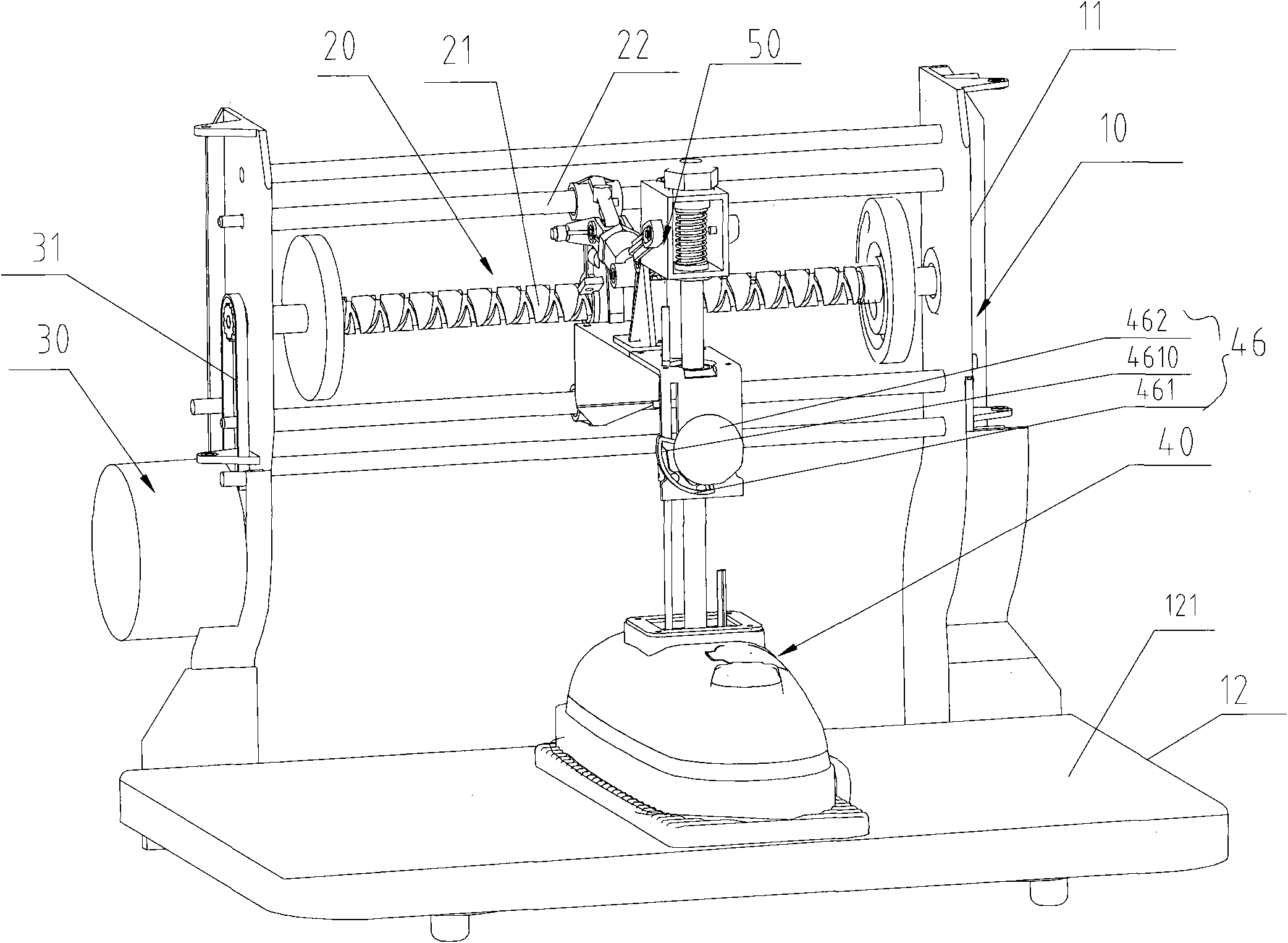

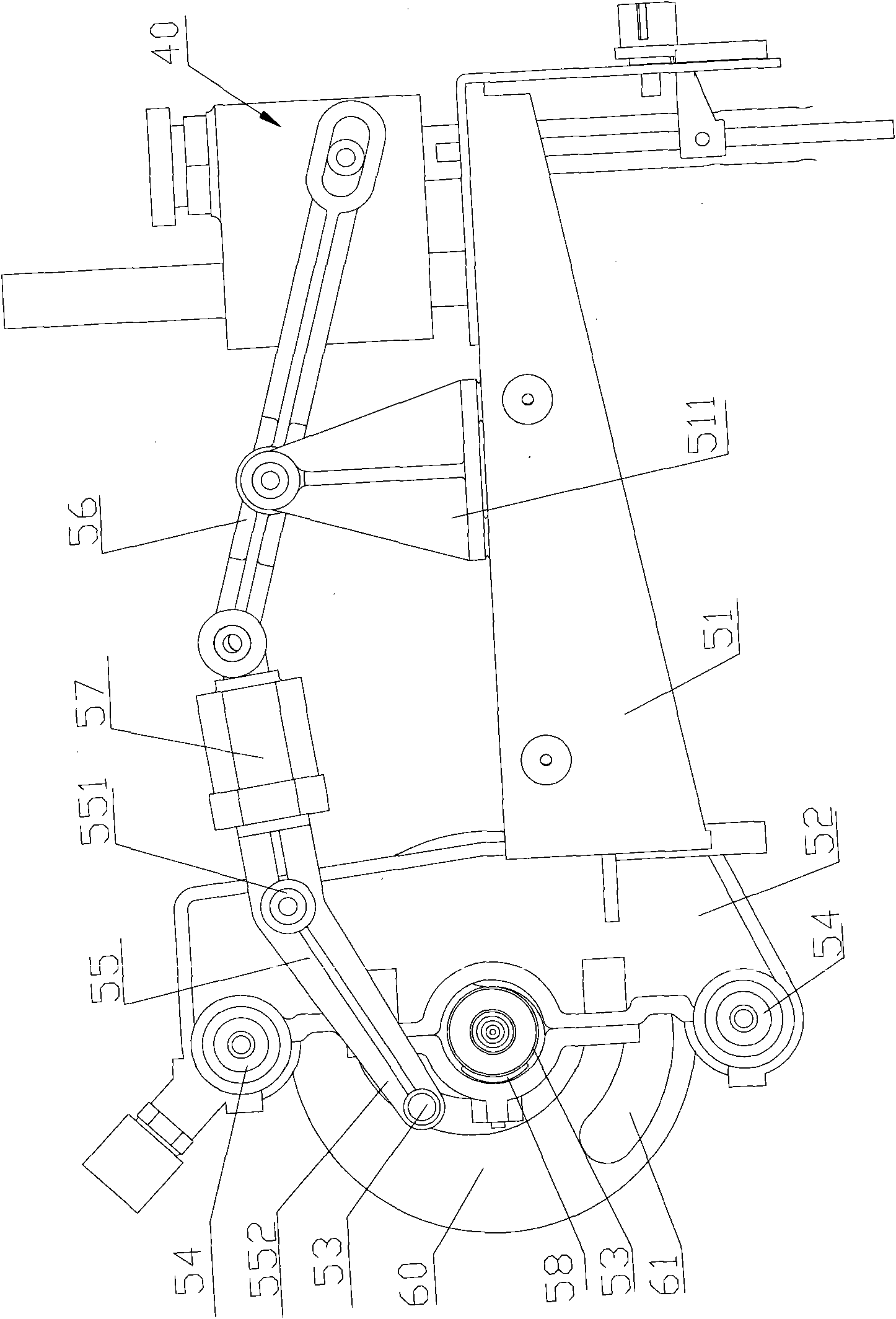

[0028] A preferred embodiment of the automatic ironing device of the present invention will be described in detail below in conjunction with the accompanying drawings.

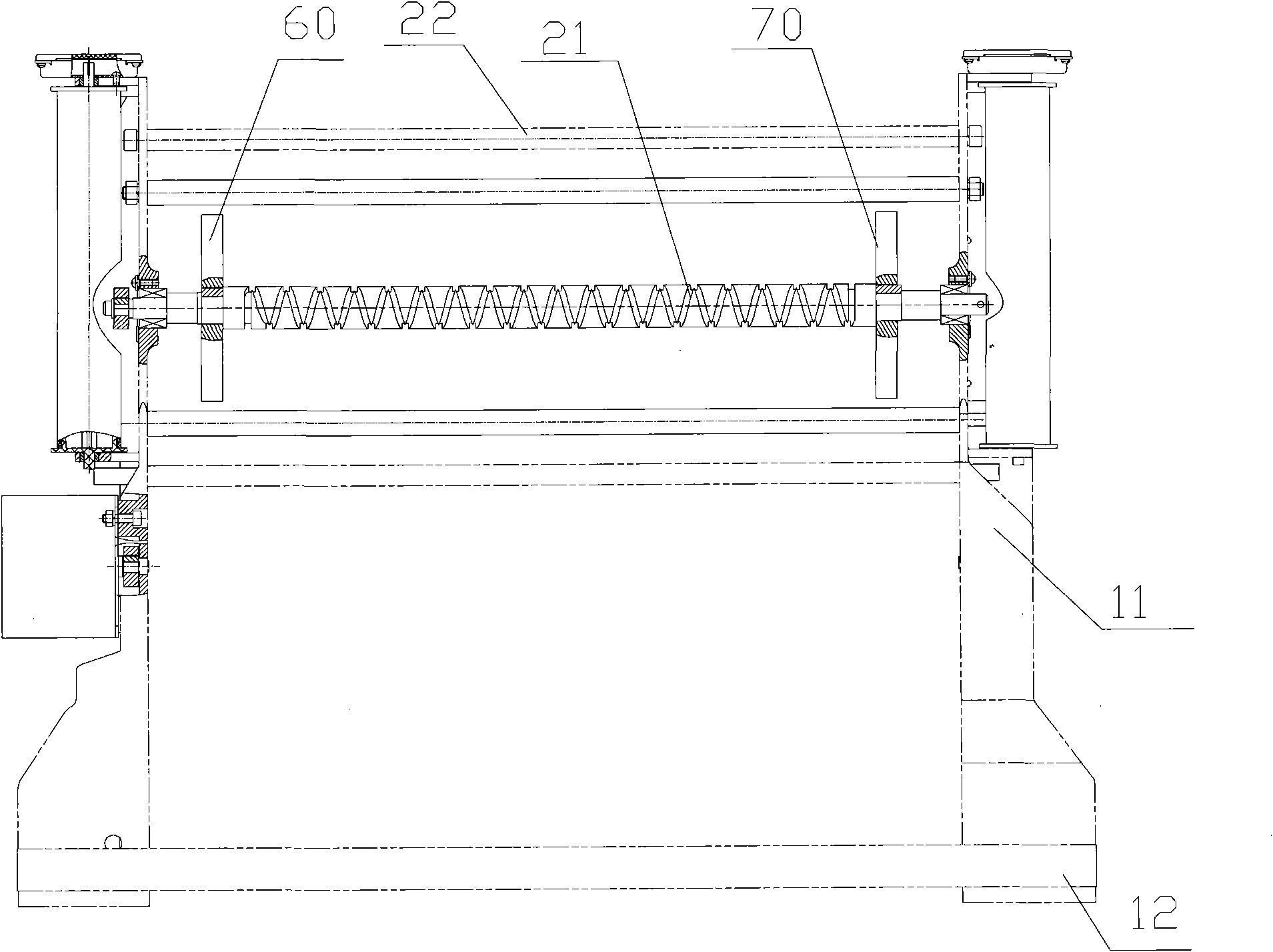

[0029] Figure 1-Figure 10 A preferred embodiment of the automatic ironing device of the present invention is described. Such as figure 1 , 2 , 3, 4, and 5, the automatic ironing equipment includes:

[0030] Supporting device 10, which includes an upright support 11 and a support 12 connected to the bottom of the support 11, the support 12 has a horizontal ironing work surface 121;

[0031] Translation transmission device 20, which includes a horizontal screw rod 21 arranged on the support 11 and a guide rod 22 parallel to the screw rod 21; the guide rod 22 can be one or multiple parallel to each other, in this embodiment, the guide rod 22 is two, respectively arranged on the upper and lower sides of the horizontal screw rod 21 and parallel to the horizontal screw rod 21;

[0032] Power unit 30, which dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com