Steam quantity controllable instant-heating garment steamer

An instant heating, steam volume technology, applied in the field of garment steamers, can solve the problems of weak steam, small coil volume, large temperature difference, etc., to improve the overall performance, obvious vaporization effect, and better ironing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0059] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

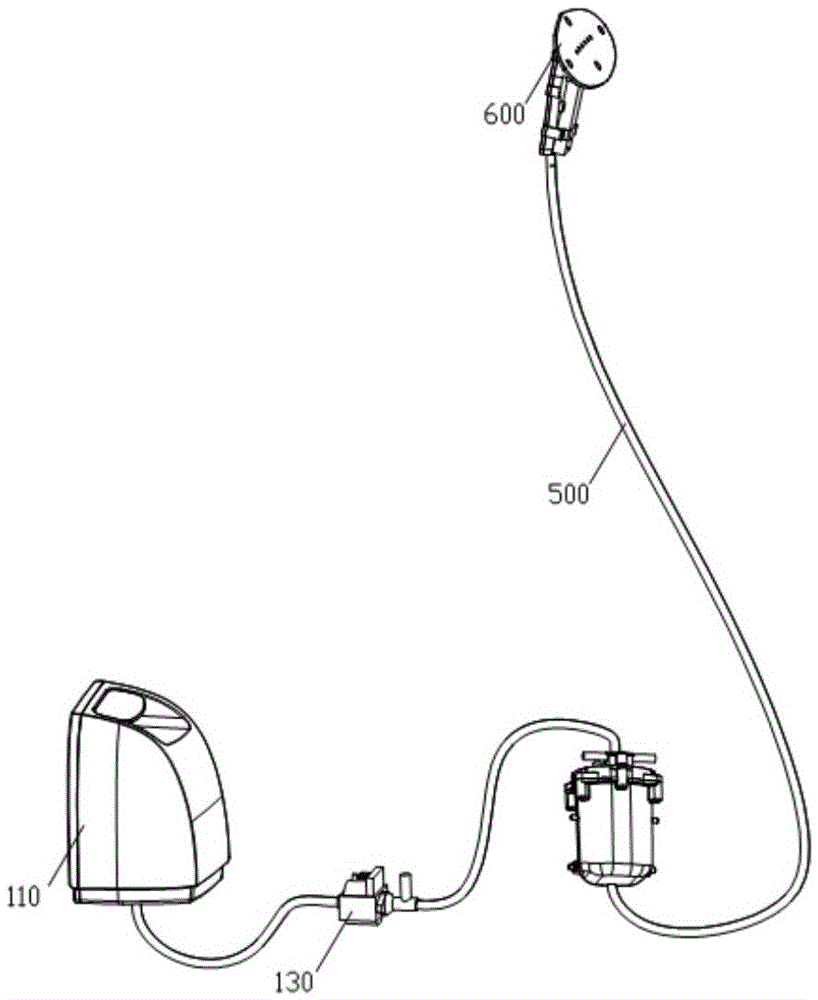

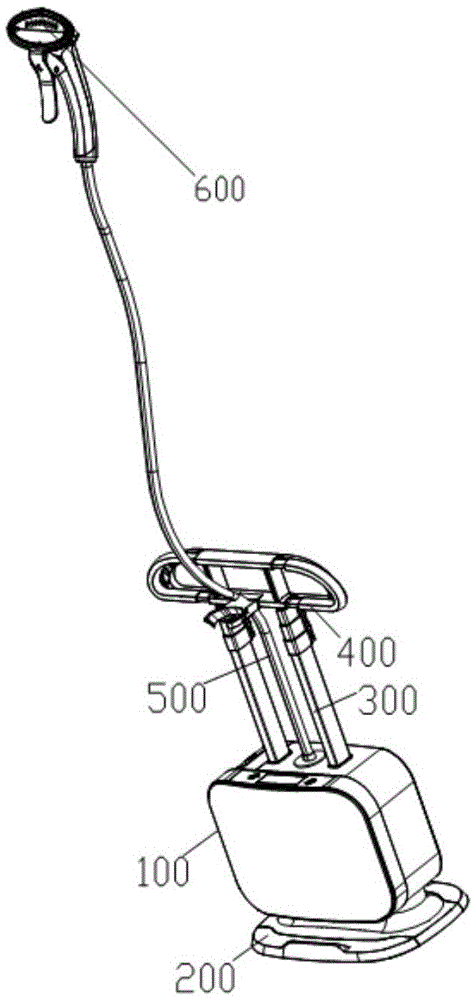

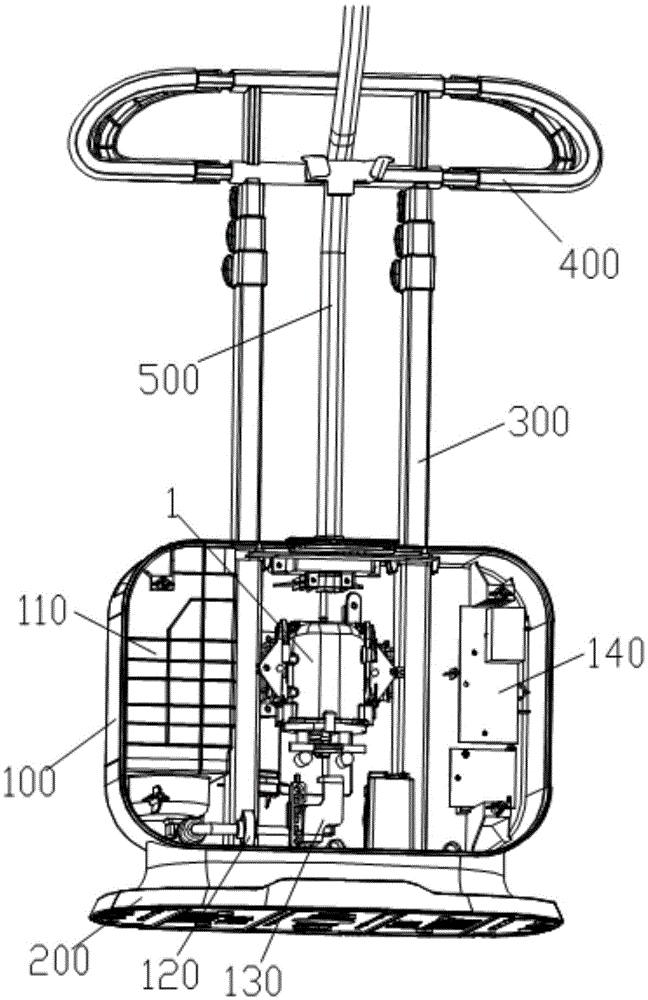

[0060] Such as Figure 1-24 As shown, the present invention provides an instant garment steamer with controllable steam volume, including: a body 100 , a primary heating pot, a water pump 130 and an ironing head 600 .

[0061] Wherein, the body 100 is provided with an accommodating cavity, the accommodating cavity is provided with a water storage tank 110 , and the lower end of the body 100 is provided with a base 200 .

[0062] The primary heating pot is fixed in the accommodating cavity by the mounting parts 700 arranged on its two side walls, and the primary heating pot is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com