Vapor-type electric iron and control method thereof

An electric iron and steam technology, which is applied to hand irons, textiles and papermaking, household appliances, etc., can solve the problems of no connection in temperature control, cumbersome production and assembly processes, and many control mechanisms, so as to achieve intimate ironing experience and production and the assembly process is simple and efficient, and the effect of simplifying the control mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

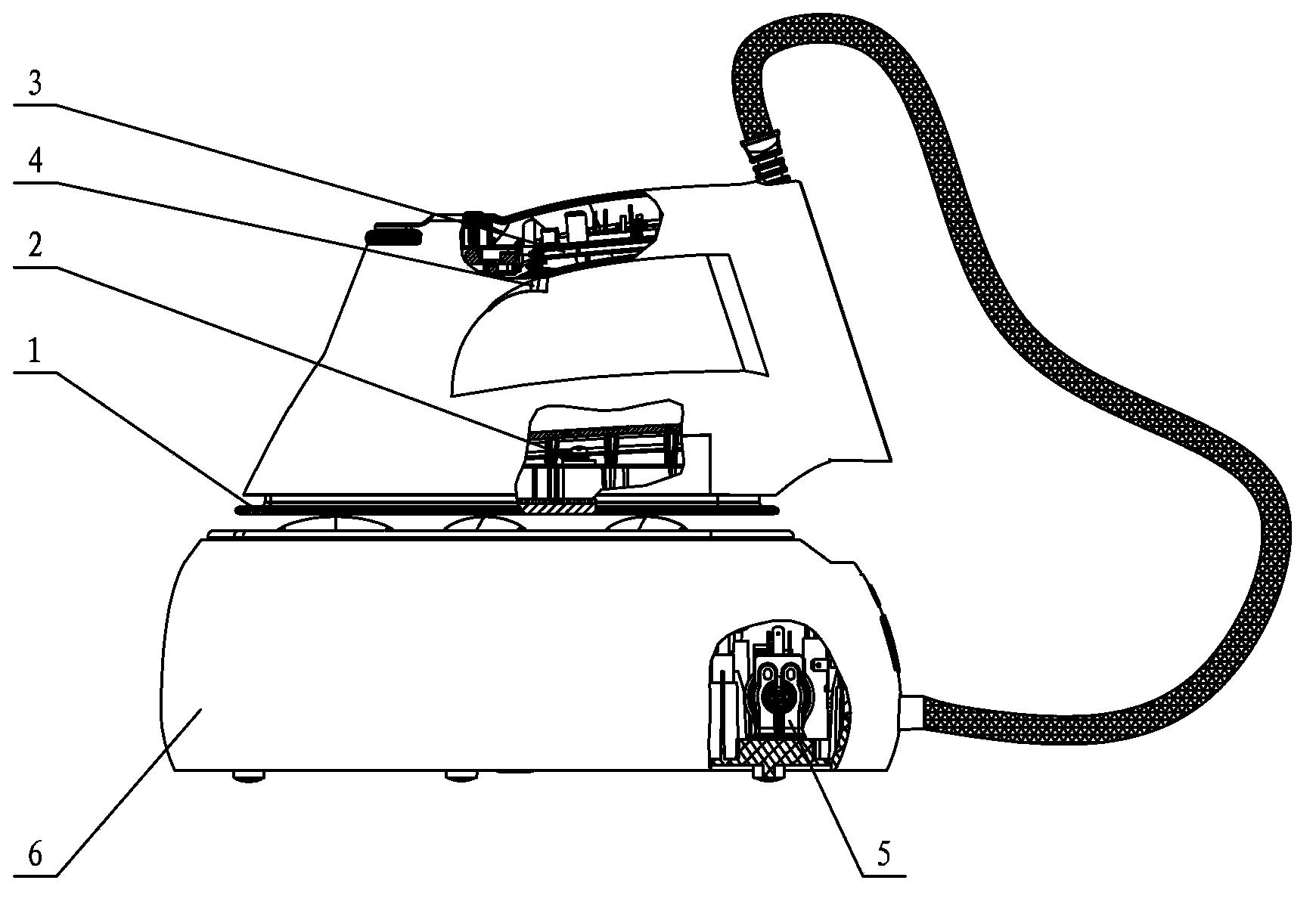

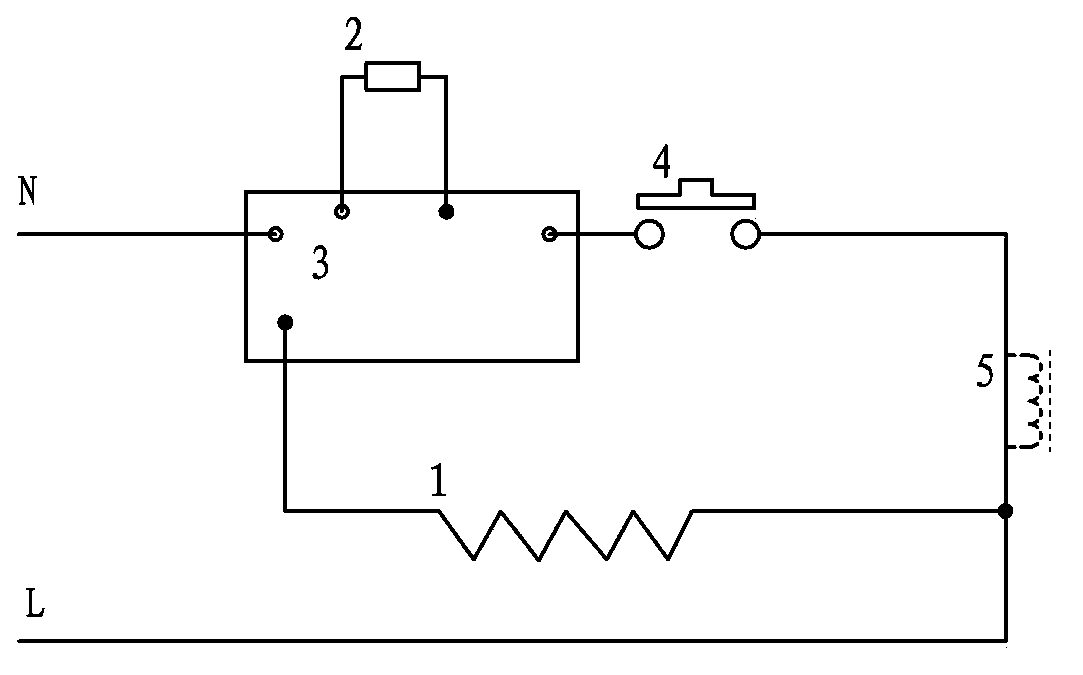

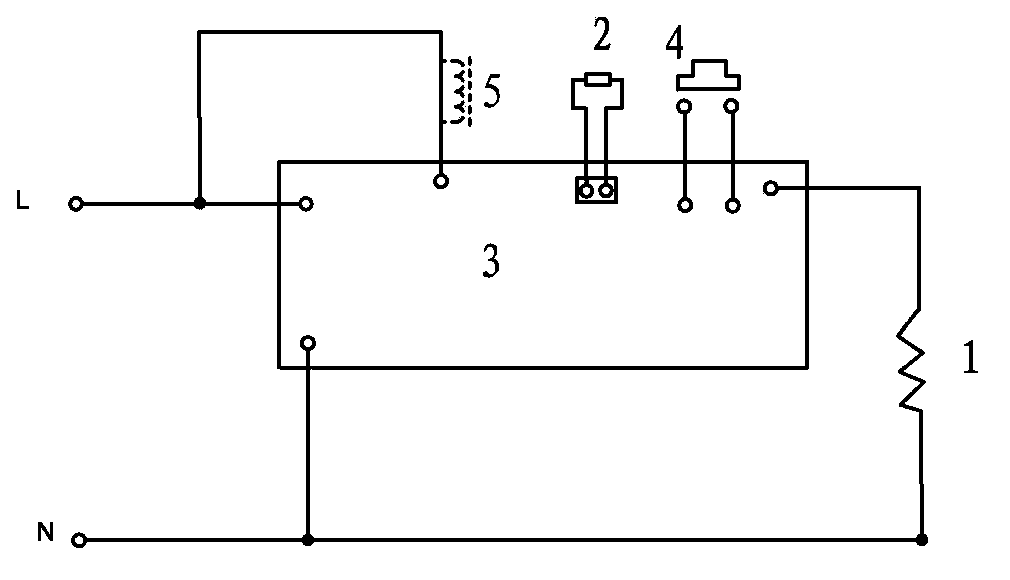

[0023] see Figure 1-Figure 3 , the steam electric iron includes a vaporization chamber arranged on the bottom plate 1 for converting water into steam, the bottom plate 1 is provided with a heating device and a steam hole, the vaporization chamber communicates with the steam hole, and the steam generated in the vaporization chamber passes through the steam The hole discharge also includes a controller 3 for controlling the amount of water entering the vaporization chamber, a temperature sensor 2 is arranged on the base plate 1, and the controller 3 is electrically connected to the heating device and the temperature sensor 2 respectively; through the temperature sensor 2 Feedback the temperature signal of the bottom plate 1 to the controller 3, and at the same time realize the two-way control of the temperature and steam volume of the bottom plate 1.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com