High-efficiency ironing machine for zipper cloth belt

A technology of ironing machine and zipper, which is applied in the direction of ironing machine, washing device, textile and paper making, etc., can solve the problems of high energy consumption, low processing efficiency, and difficult to control ironing temperature, and can improve the feeding speed, improve the Production efficiency, the effect of improving ironing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

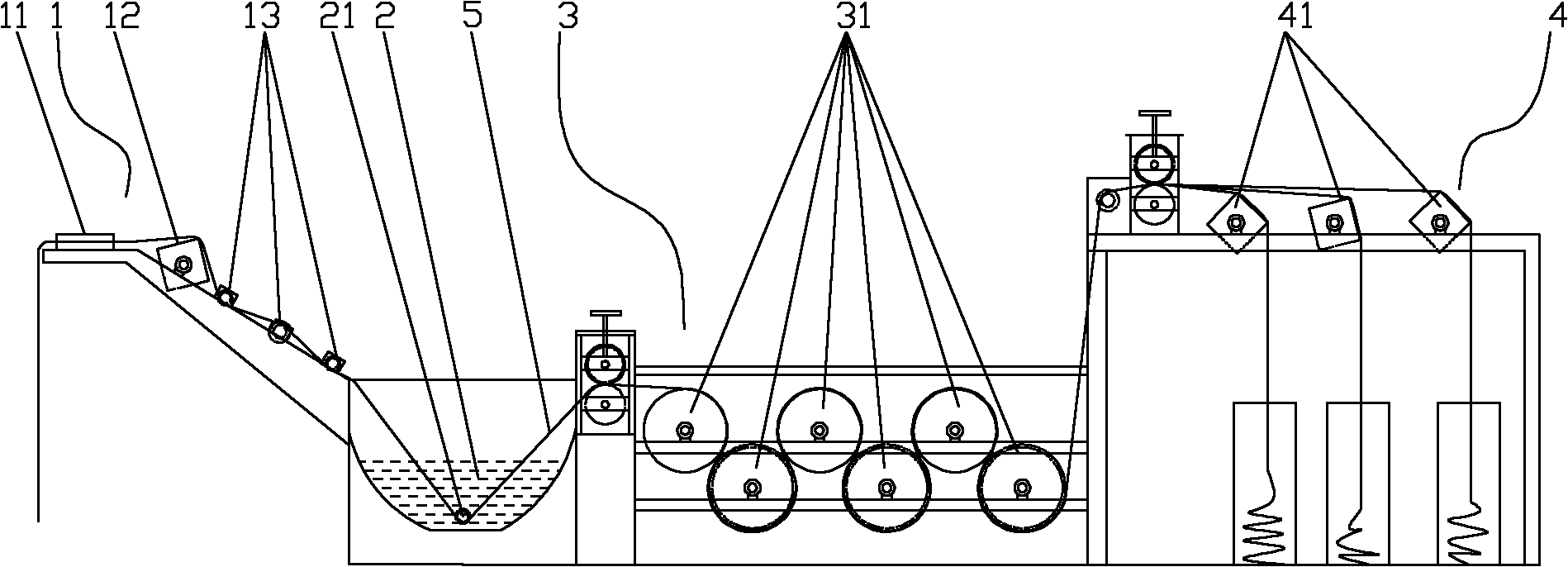

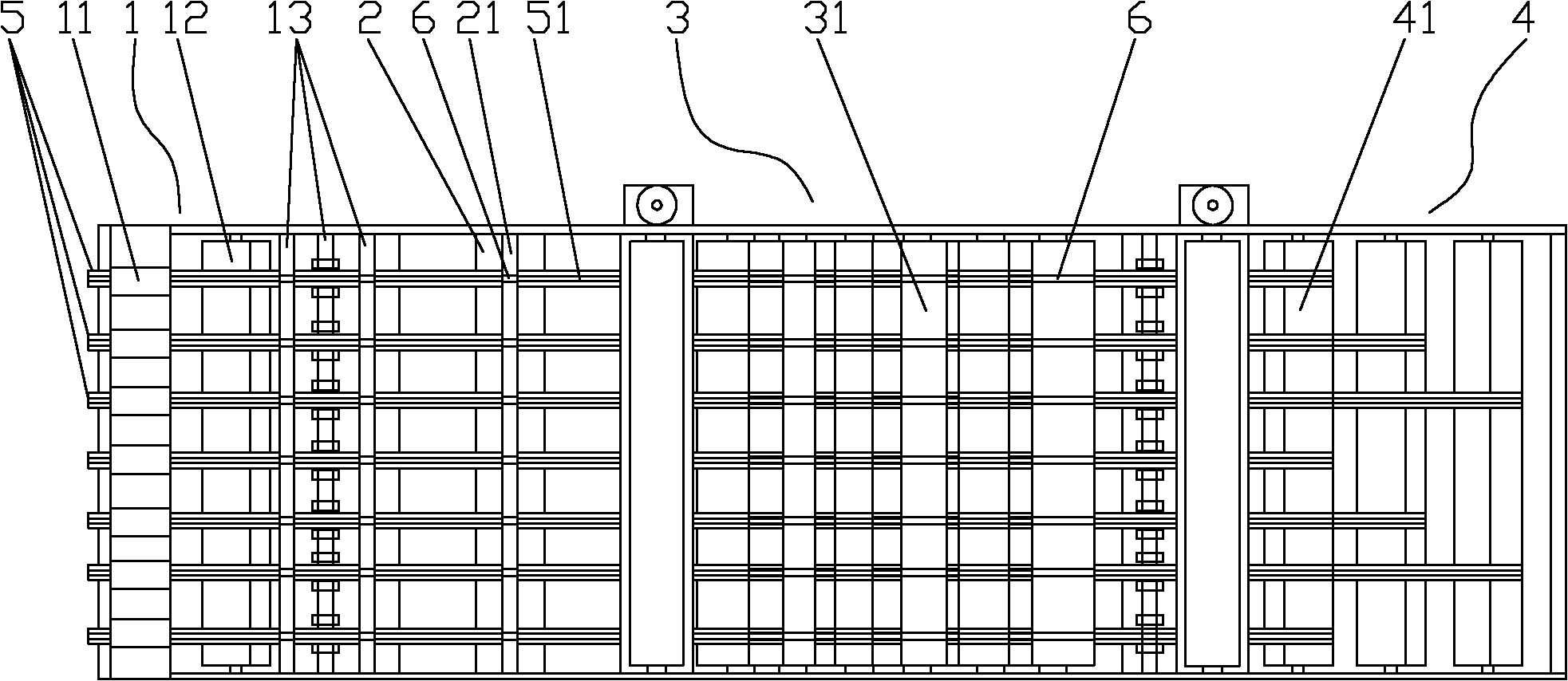

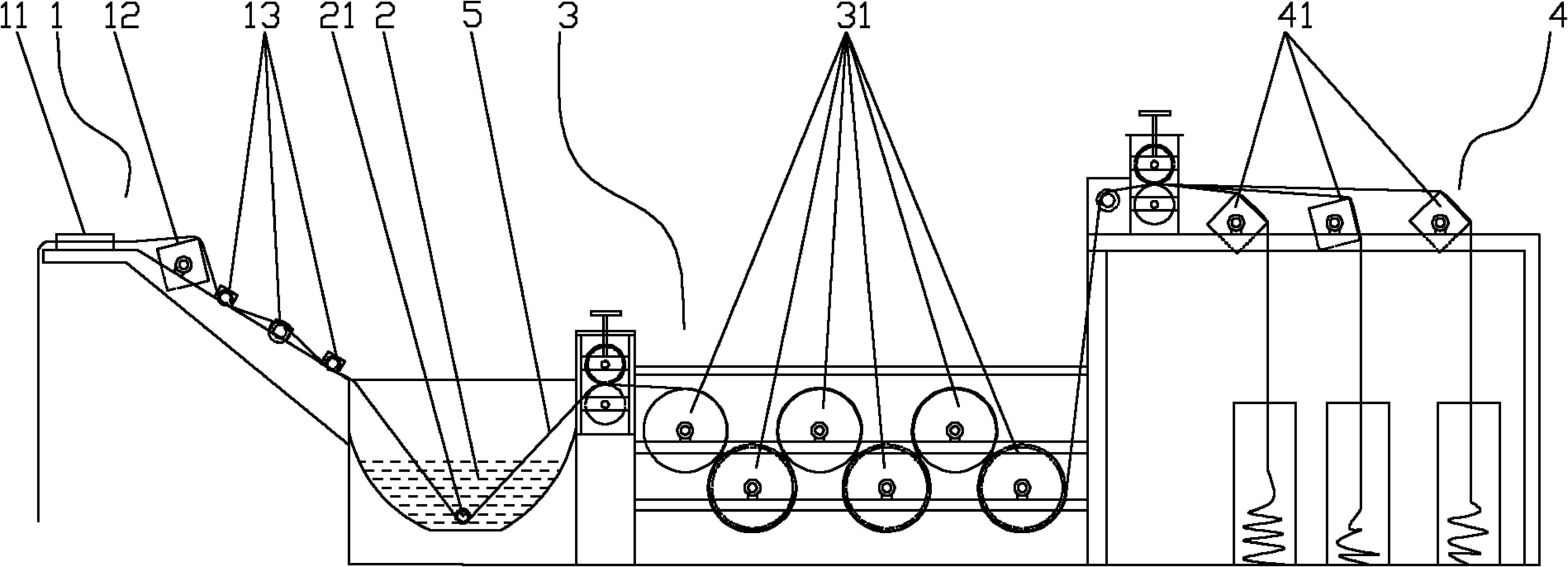

[0011] like figure 1 , figure 2 As shown, the high-efficiency ironing machine of the present invention includes a guide mechanism 1, a water tank 2, an ironing mechanism 3 and a packaging mechanism 4, and the zipper tape 5 passes through the guiding mechanism 1, the water tank 2, the ironing mechanism 3 and the packaging mechanism 4 in sequence The guide mechanism 1 includes a conduit 11, a friction roller 12 and a guide roller 13, the bottom of the water tank 2 is provided with a guide roller 21, and the ironing mechanism 3 is an electric heating roller that is continuously arranged parallel to each other up and down. 31. The zipper tape 5 is wound in an S shape on the electric heating roller 31, and the packing mechanism 4 is a rubbing roller 41 parallel to each other. The electric heating roller 31 and the rubbing rollers 12 and 41 rotate at the same speed, driving the zipper tape 5 to move towards the packing mechanism 4 . The guide mechanism 1 includes a conduit 11, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com