Balloon catheter and manufacturing method thereof

A balloon catheter and balloon technology are applied in the field of catheters for expanding various pipelines of human tissues and their manufacturing fields, which can solve problems such as poor transmission performance and poor controllability, and achieve good pushing performance, good fit, and blood vessels. Damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

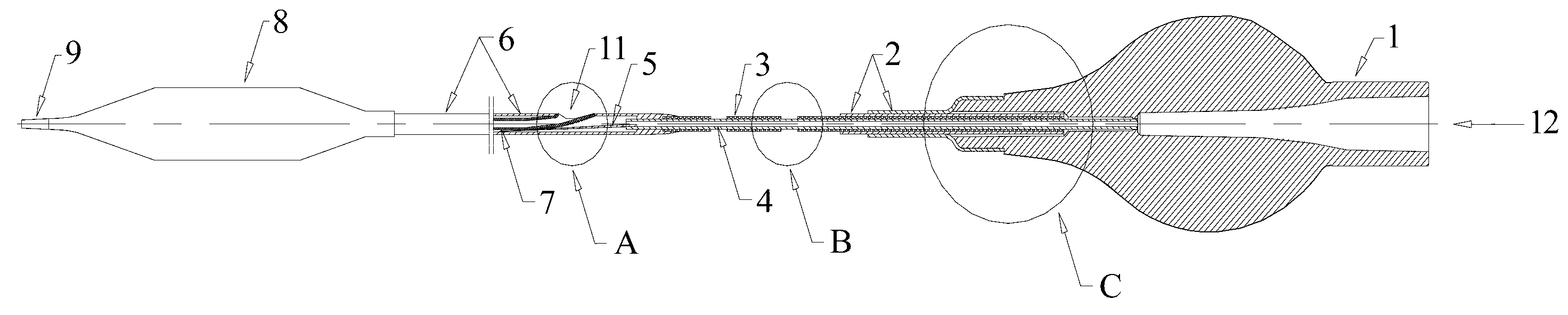

[0060] The present invention will be further described in detail below with reference to the drawings and embodiments. The balloon catheter of the present invention is provided with two structures: a rapid exchange balloon catheter and an integral exchange balloon catheter.

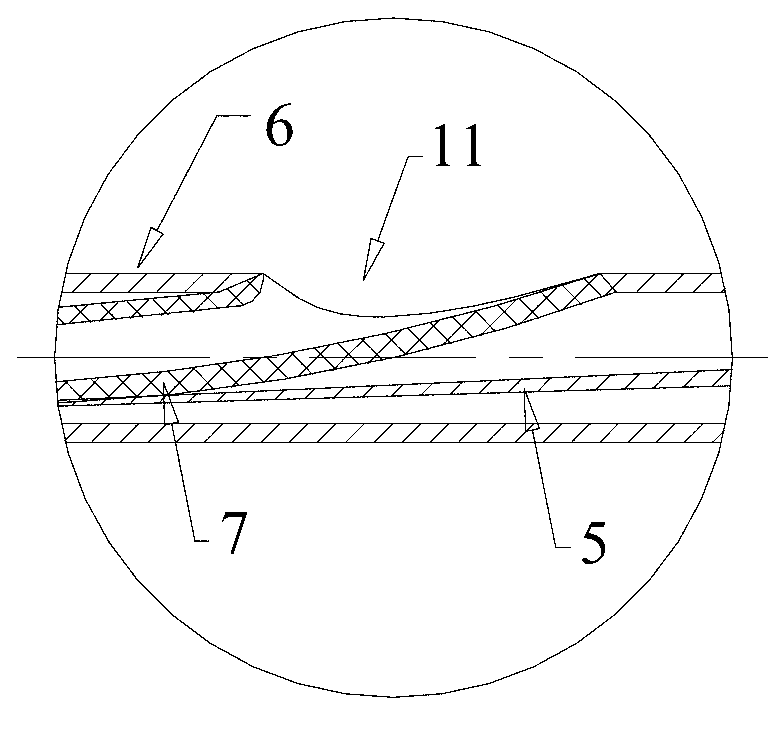

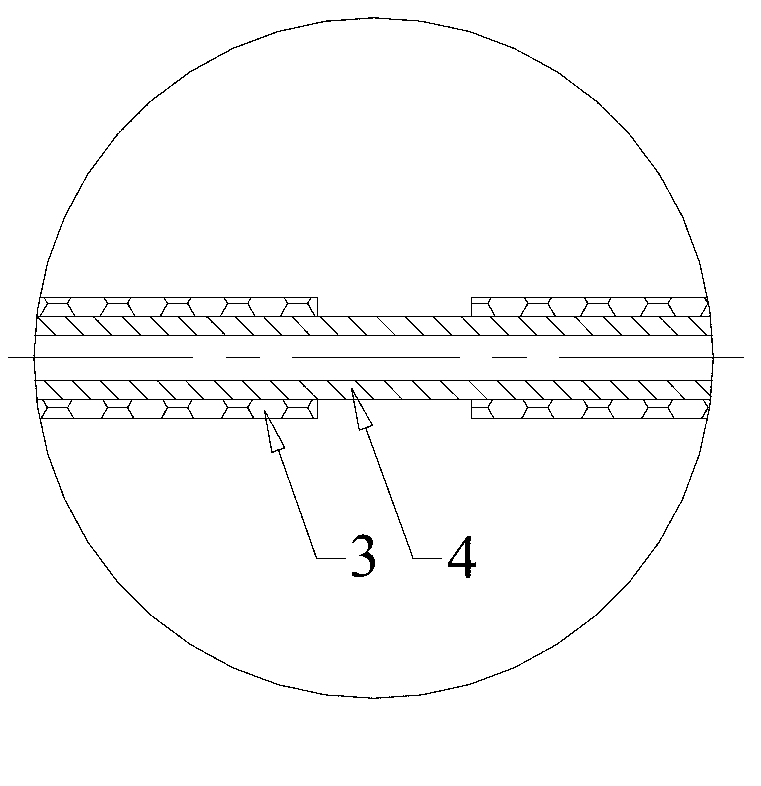

[0061] Such as figure 1 As shown, the rapid exchange balloon catheter, from the proximal end to the distal end, consists of an inner conical Luer connector needle seat (needle seat) 1, a proximal tube body 4 with a lubricating layer 3, and a tube body reinforcement wire inside. 5, the distal outer tube 6, the balloon 8 and the catheter tip 9 are connected together. The distal outer tube 6 and the balloon 8 are provided with a visible marking ring 13 (such as Figure 11-Figure 13 Shown) the inner tube 7. The axis of the inner hole of the needle seat 1 is a straight line.

[0062] Such as image 3 As shown, the proximal tube body 4 is tubular in shape, made of stainless steel or nickel-titanium memory alloy, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com