Method and devices for preparing microscopic samples with the aid of pulsed light

An electron microscope and sample technology, applied in the field of microscope samples, can solve the problems of not always successful, slow preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings. Components that are structurally and functionally similar to each other are identified by reference numerals having the same numerals but differentiated by adding different letters. For the description of these components, reference is also made to the preceding and following corresponding parts of the description, respectively.

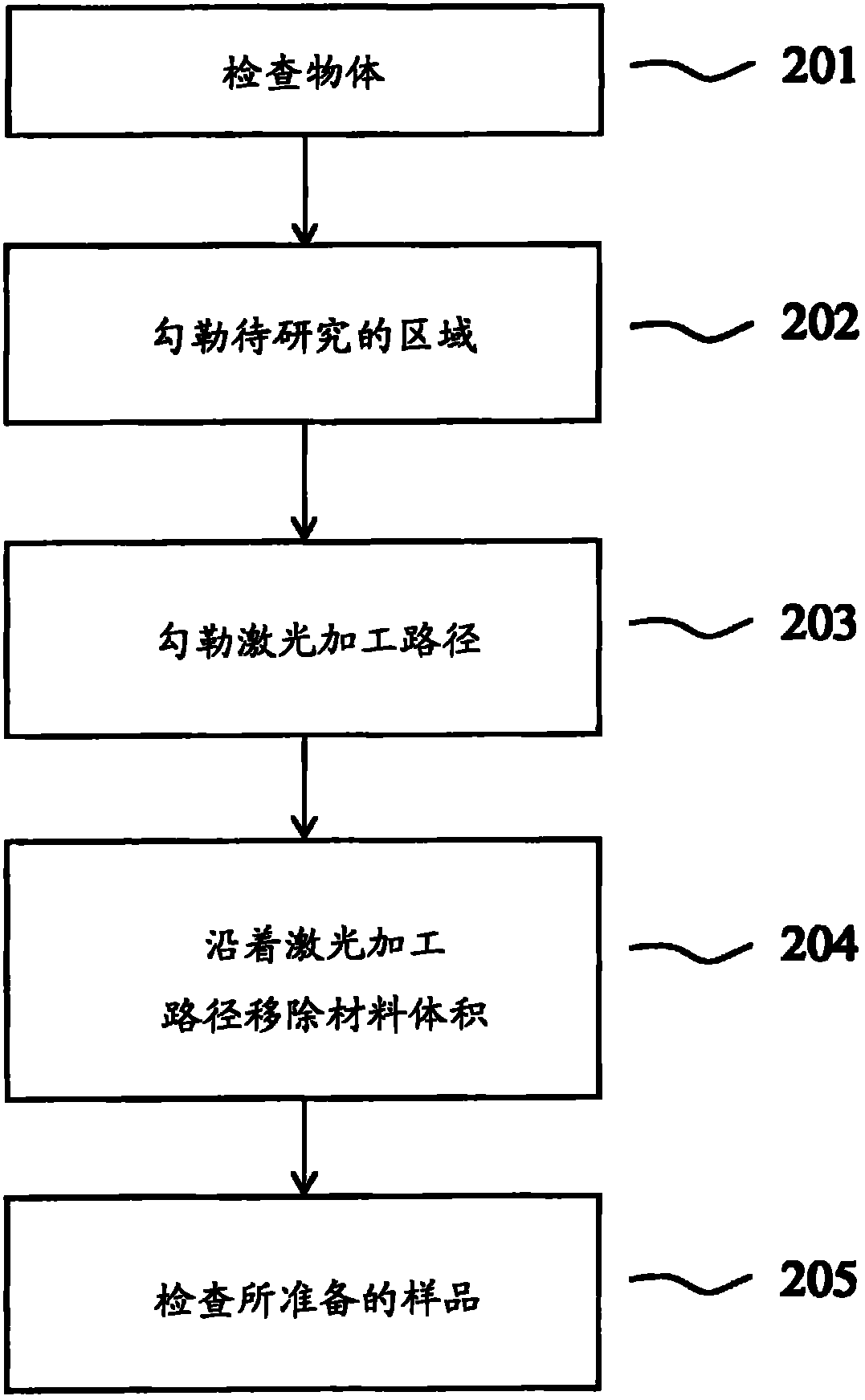

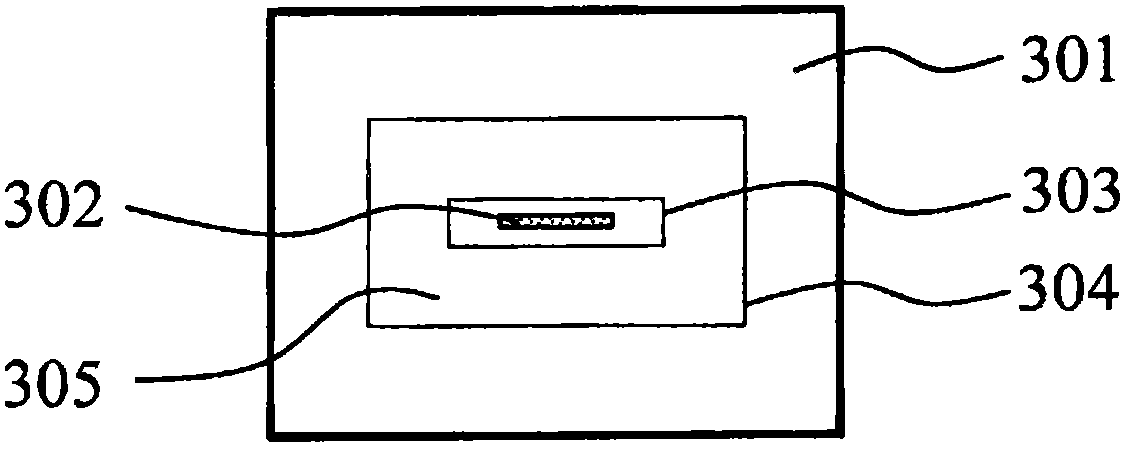

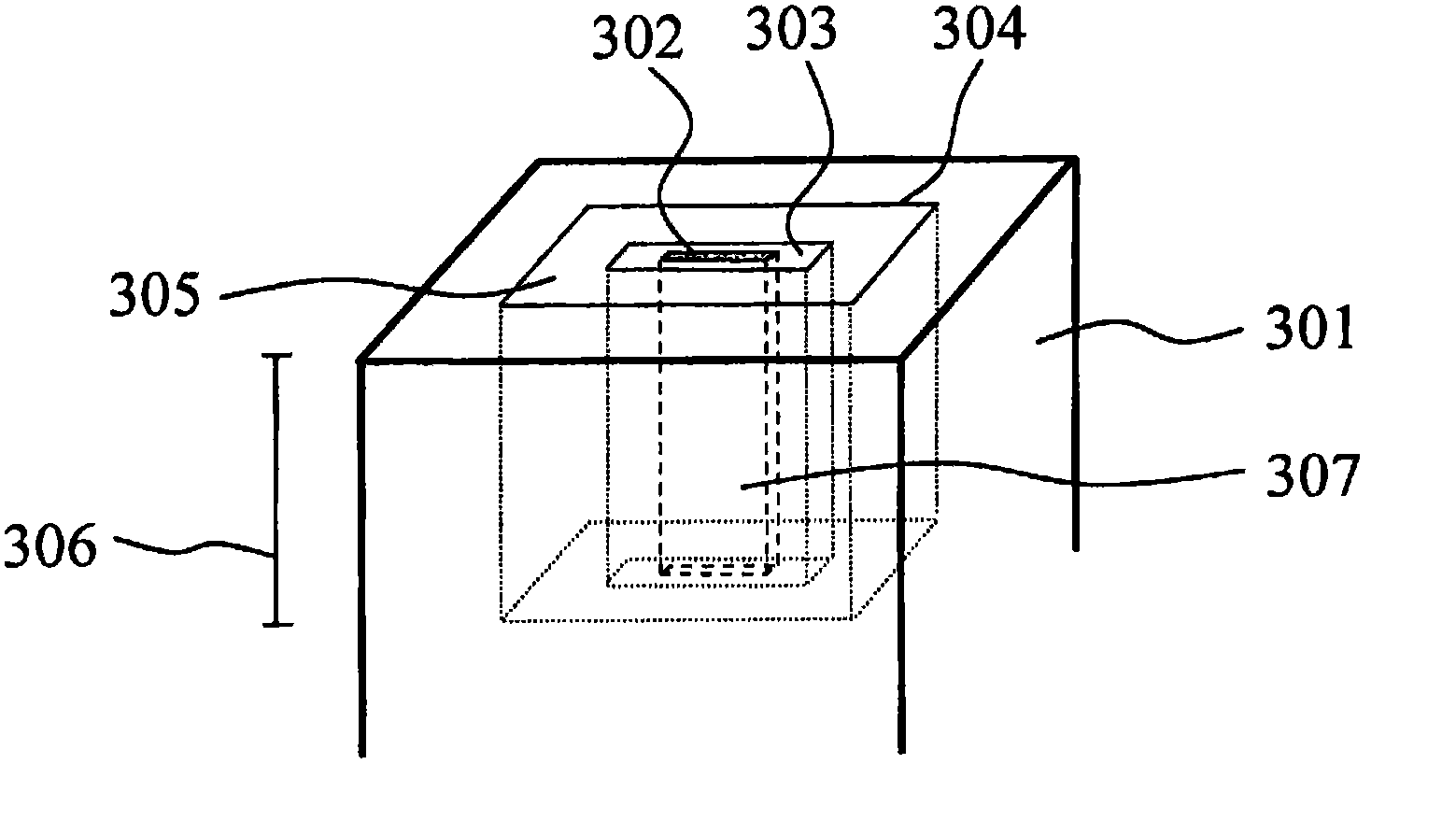

[0069] figure 1 A flowchart representing the method according to the invention. The object from which the sample is to be prepared is placed in the processing chamber of the processing system according to the invention. In step 201 the object is checked. Inspection may be performed using an electron microscope or a focused ion beam, or a combination of electron microscope and focused ion beam. In any event, an image is recorded, which can be stored into memory for possible later use. In step 202 , the part of the object to be s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com