Robot stacking system and stacking method thereof

A stacking system and robot technology, applied in the stacking, transportation and packaging of objects, can solve the problems of disordered material stacking, inconsistent incoming material size, low efficiency, etc., to improve efficiency and reduce workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

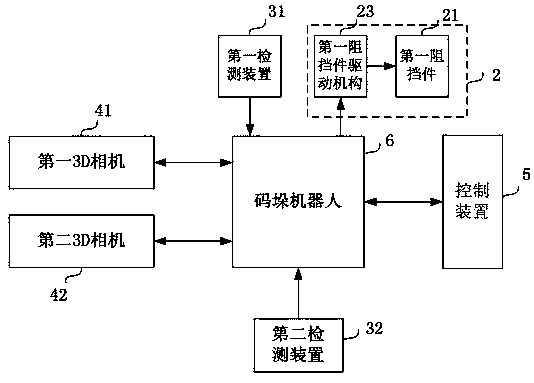

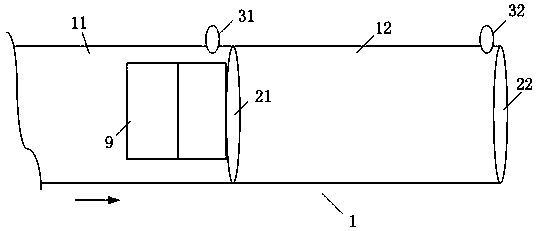

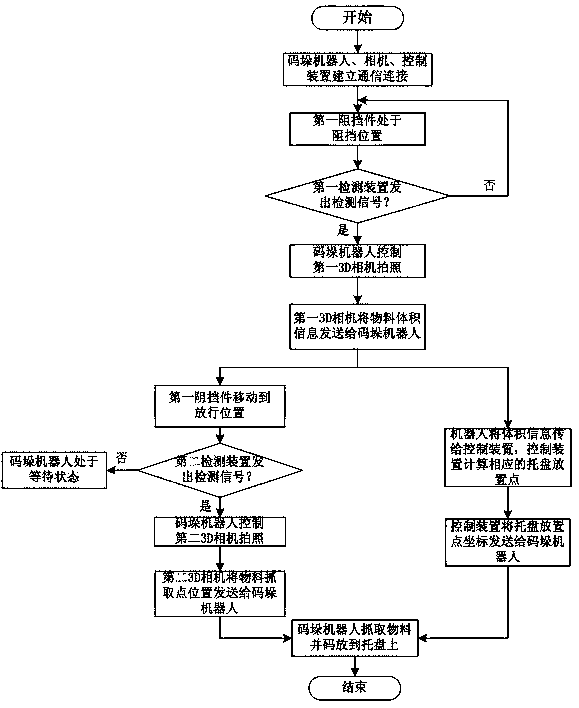

[0041] figure 1 A functional block diagram of an embodiment of the robot palletizing system of the present invention is shown, figure 2 A schematic diagram of a conveying mechanism according to an embodiment of the present invention is shown. see figure 1 and figure 2, according to an embodiment of the present invention, the robot palletizing system includes a conveying mechanism 1, a first blocking mechanism 2, a first detection device 31, a second detection device 32, a first 3D camera 41, a second 3D camera 42, and a control device 5 and palletizing robot 6.

[0042] The conveying mechanism 1 has a main conveying area 11 and a buffer conveying area 12 . In this embodiment, the conveying mechanism 1 is a roller conveying mechanism, but it is not limited thereto.

[0043] The first blocking mechanism 2 includes a first blocking membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com