Large-scale piled material volume two-side parallel measuring device and method

A technology of parallel measurement and measurement device, applied in the direction of measurement device, optical device, instrument, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

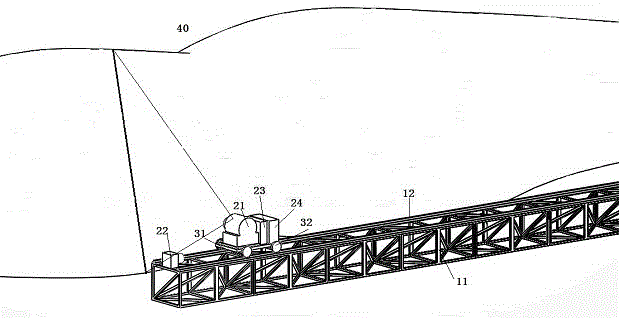

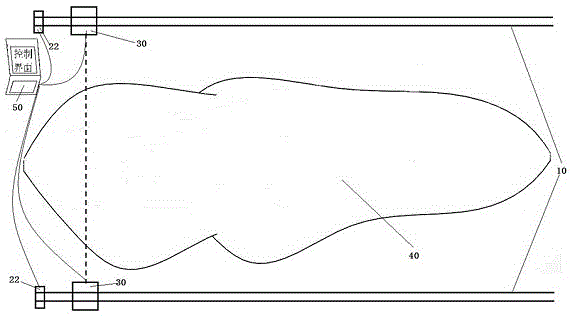

[0025] see figure 1 and figure 2 , the parallel measurement device on both sides of the volume of large-scale accumulated materials includes two sets of laser scanning devices arranged in parallel, each of which has a laser scanner (21), a laser ranging sensor (22), and a trolley controller ( 23), a trolley driver (24), a pair of rails (12), a rail frame (11) and a carrying trolley (30), sharing a computer (50), characterized in that the laser scanner (21) is Installed on the carrying trolley (30), through the uniform movement of the trolley (30), the material pile (40) is scanned line by line, and the laser ranging sensor (22) installed at one end of the track (10) synchronously measures the trolley ( 30) and the position of the laser scanner (21), the information of the two sets of sensors is transmitted to the computer (50) and after fitting, the complete outline information of the stockpile (40) can be presented, and then the expected volume of the stockpile can b...

Embodiment 2

[0028] Implementation example 2: Measurement of the volume of raw material piles in steel mills

[0029] see figure 2 As shown, raw materials in steel mills generally have fixed stacking positions, so the present invention is suitable for stockpile measurement in large raw material stockyards in steel mills. On both sides of the stockpile (40), the transport vehicle roads are reserved, and the two sets of laser scanning measurement equipment are fixed on the ground, while ensuring that the tracks (10) of the two sets of equipment are parallel to each other, and the track (10) is determined according to the actual site requirements. length. Adjust the measurement direction of the laser ranging sensor (22) so that it always faces the laser scanner (21) to measure its offshore distance as the one-dimensional information of the stockpile contour model.

[0030] An operator operates the laser scanning measurement system by using a control interface on a computer (50). After the...

Embodiment 3

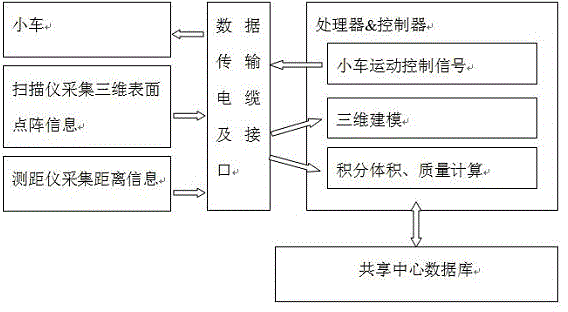

[0033] This implementation example is basically the same as the first implementation example, except that the laser scanning measurement system includes a laser scanning measurement device and data acquisition, processing and communication modules. see figure 1 and image 3 , the stockpile profile information collected by the laser scanner (21) and the laser ranging sensor (22) is transmitted to the computer (50) that can process the data through the data transmission cable and interface with a certain communication protocol, and the obtained data is simulated by discrete points. The contour model of the stockpile is reconstructed by combining the scanning curve, and the volume and mass information of the stockpile are calculated by the method of integral reconstruction. This information can be passed to the management through the shared platform, and the management can make timely decisions based on the production plan. The invention is applicable to the volume and quality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com