Casting design method of 38W machine body

A casting design and machine body technology, applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of easy cracks in castings, high quality requirements, complex structures, etc., to reduce sand sticking, ensure casting quality, improve The effect of molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with specific embodiment, technical content of the present invention is elaborated:

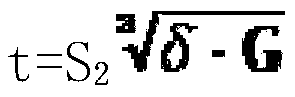

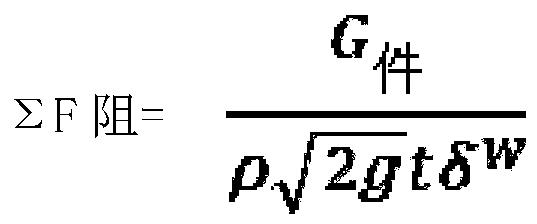

[0035] A casting design method for a 38W body. The main cavity of the 38W body casting is a V-shaped structure, the lower part is an air cavity, and there are multiple shaft stops in the middle. The casting design method is sequentially performed by casting design-pouring design-riser design. Optimization, the design requirements are as follows:

[0036] 1) Casting design:

[0037] a. Pouring process confirmation: choose the vertical pouring method for pouring. The vertical pouring system refers to the pouring method in which the cylinder hole of the machine body faces downward and the foot plate faces upward, and resin sand mold is used for pouring;

[0038] b. Modeling: three out-of-box and eight-model models are adopted, namely the lower box, middle box and upper box. The lower box is made of air cooling, axle box core and side wall core model; the middle box d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com