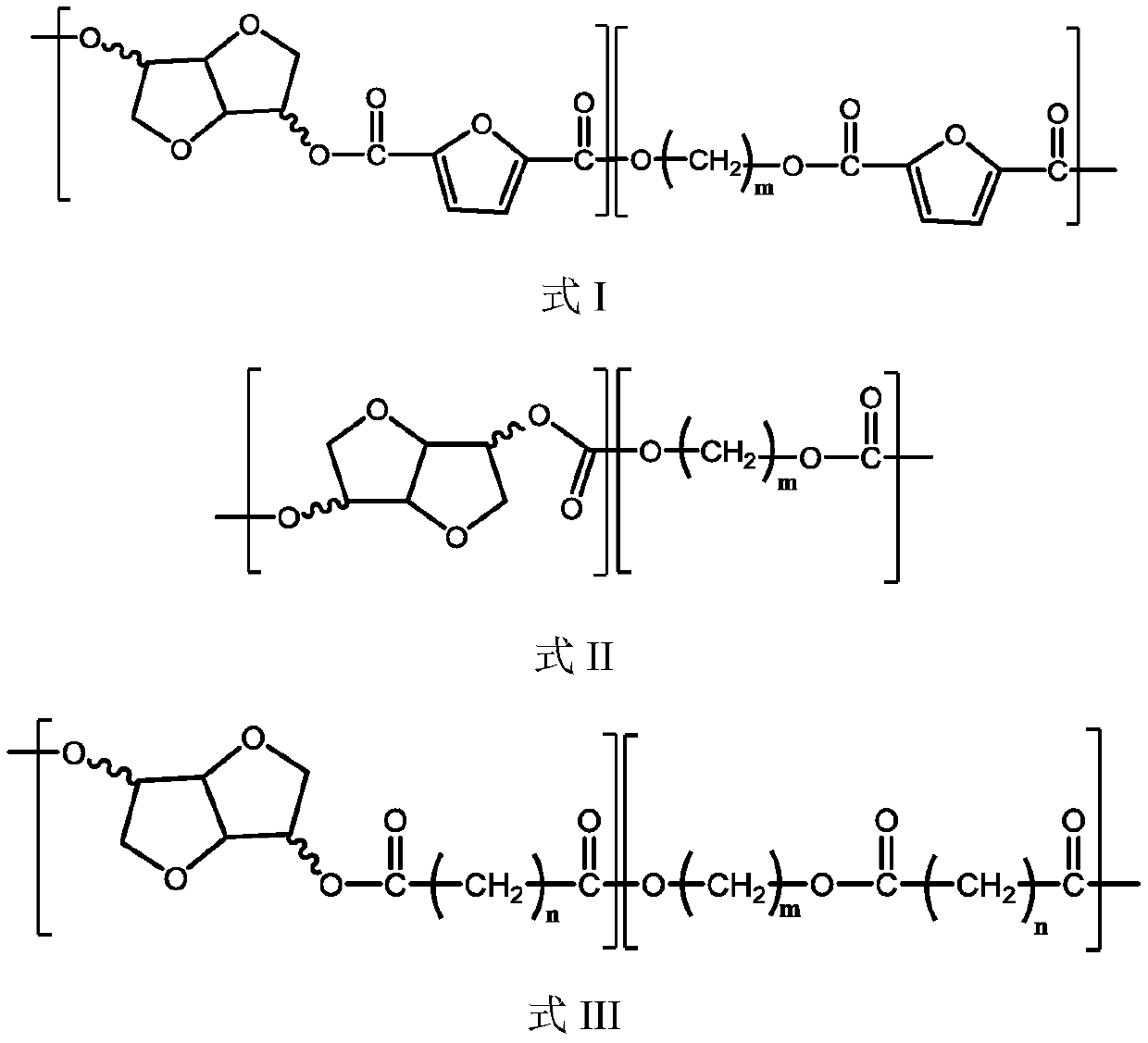

1,4;3,6-dianhydro mannitol modified furan dicarboxylic acid-based random copolymer, preparation method and applications thereof

A technology of random copolymer and furandicarboxylic acid, applied in the field of polymer materials, can solve the problems of increasing production cost, reducing the proportion of bio-based monomer units, etc., and achieves increased molecular weight, high glass transition temperature, and high intrinsic viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Embodiment 1. prepare the polybutylene furandicarboxylate random copolymer of isosorbide modification

[0072] (1) At room temperature, in a 250mL glass flask, add 11.7g (0.08mol) isosorbide, 36.0g (0.40mol) dimethyl carbonate and 0.0026g transesterification catalyst lithium acetylacetonate under nitrogen atmosphere, (isosorbide The molar ratio of sorbitol to dimethyl carbonate is 1:5), stirred and reacted at 60°C for 3 hours, then gradually raised the temperature to 200°C, and completely distilled out the by-product methanol produced by the reaction to obtain isosorbide polycarbonate Esters prepolymer O1; characterized by NMR, its transesterification rate is 90%.

[0073] (2) In a 250mL glass flask, add 18.6g (0.12mol) of furandicarboxylic acid, 21.8g (0.24mol) of 1,4-butanediol and 0.002g of esterification catalyst titanium glycol (furan) under a nitrogen atmosphere The molar ratio of dicarboxylic acid to 1,4-butanediol is 1:2.0), start stirring at 160°C, gradually r...

Embodiment 2

[0085] Embodiment 2. prepare the polybutylene furandicarboxylate random copolymer of isosorbide modification

[0086] (1) At room temperature, in a 500mL glass flask, add 17.6g (0.12mol) isosorbide, 216g (2.4mol) dimethyl carbonate and 0.0016g transesterification catalyst potassium hydroxide, (isosorbide The molar ratio of alcohol to dimethyl carbonate is 1:20), stirred and reacted at 60°C for 3 hours, then gradually raised the temperature to 200°C, and completely distilled out the by-product methanol produced by the reaction to obtain isosorbide polycarbonate The prepolymer O1; the transesterification rate is 95% by NMR.

[0087] (2) In a 250mL glass flask, add 12.4g (0.08mol) of furandicarboxylic acid, 145g (1.6mol) of 1,4-butanediol and 0.0016g of esterification catalyst titanium glycol (furand dicarboxylate) under a nitrogen atmosphere. The molar ratio of formic acid to 1,4-butanediol is 1:20), start stirring at 160°C, gradually raise the temperature to 200°C, and react u...

Embodiment 3

[0089] Embodiment 3. prepare isosorbide modified polybutylene furandicarboxylate random copolymer

[0090] (1) At room temperature, in a 1000mL glass flask, add 23.4g (0.16mol) isosorbide, 701g (4.8mol) dimethyl carbonate and 0.00026g transesterification catalyst stannous octoate, (isosorbide The molar ratio of alcohol to dimethyl carbonate is 1:30), stirred and reacted at 60°C for 3 hours, then gradually raised the temperature to 200°C, distilled out the by-product methanol produced by the reaction until the reaction was complete, and stopped the reaction to obtain The prepolymer O1 of isosorbide polycarbonate; the transesterification rate is 98% as characterized by NMR.

[0091] (2) In a 50mL glass flask, add 3.1g (0.02mol) furandicarboxylic acid, 2.7g (0.03mol) 1,4-butanediol and 0.002g of esterification catalyst tetrabutyl titanate ( The molar ratio of furandicarboxylic acid to 1,4-butanediol is 1:1.5), start stirring at 160°C, gradually raise the temperature to 200°C, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com