Hydrolysis-resistant polyester composition and preparation method of the composition solution and application thereof

A composition and hydrolysis-resistant technology, applied in the field of polyester, can solve the problems of anti-hydrolysis agents in the polluted environment, difficult process control, low content of diethylene glycol, etc., and achieve the effects of easy use, high intrinsic viscosity, and good hue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

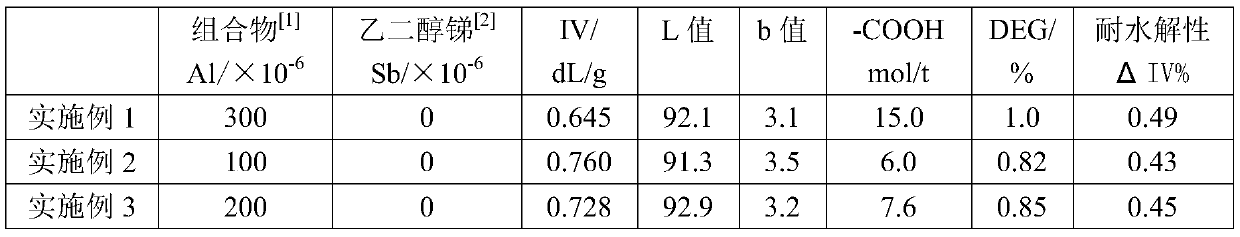

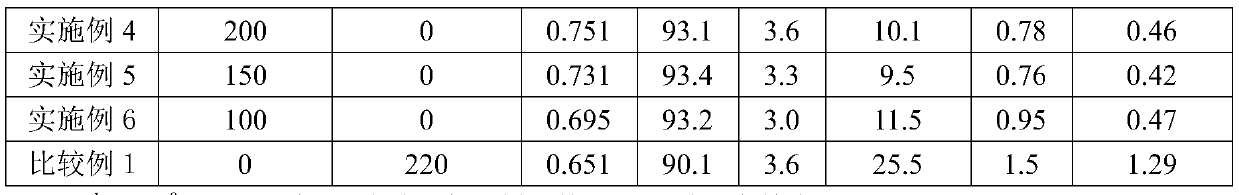

Examples

Embodiment 1

[0037] Aluminum hydroxide is 1 part, potassium hydroxide is 1 part, ethylene glycol is 5 parts, trimethyl phosphate is 0.5 part, tetramethyl titanate is 0.25 part, polyethylene glycol (600) is 0.2 part, each Parts are expressed in moles of substance.

[0038] First weigh 15.6g (0.2mol) of aluminum hydroxide, 11.2g (0.2mol) of potassium hydroxide, and 62g (1mol) of ethylene glycol and place them in the reactor, and stir and react for 1 hour to become an intermediate solution. Add 11.0 g (0.05 mol) of tetramethyl titanate, 14.0 g (0.1 mol) of trimethyl phosphate, 24 g (0.04 mol) of polyethylene glycol (600), and stir the reaction for 3 hours at 80°C, remove A small molecule with a low boiling point becomes a stable composition solution A after cooling to room temperature.

[0039] Preparation of PET

[0040] In reactants 500g terephthalic acid (PTA), 260g ethylene glycol (EG) and titanium dioxide with a particle size of 0.3μ (based on the amount of polyester produced, the amou...

Embodiment 2

[0043] Aluminum acetate is 1 part, sodium hydroxide is 8 parts, ethylene glycol is 20 parts, triethyl phosphate is 4 parts, tetraethyl titanate is 1 part, polyethylene glycol (1500) is 0.05 parts, each Measured in moles of substance.

[0044] First weigh 40.8g (0.2mol) of aluminum acetate, 64g (1.6mol) of sodium hydroxide, and 248g (4mol) of ethylene glycol and place them in the reaction kettle, stir and react for 2 hours to form an intermediate solution, and add titanium to the intermediate solution. 45.6 g (0.2 mol) of tetraethyl phosphate, 145.6 g (0.8 mol) of triethyl phosphate, 15.0 g (0.01 mol) of polyethylene glycol (1500), and stirred for 1 hour under the condition of raising the temperature to 170° C. A small molecule with a boiling point becomes a stable composition solution B after cooling to room temperature.

[0045] Preparation of PET

[0046] The reactant 500g terephthalic acid (PTA), 260g ethylene glycol (EG) and calcium carbonate with a particle diameter of ...

Embodiment 3

[0049] Aluminum glycolate is 1 part, sodium hydroxide is 1 part, ethylene glycol is 10 parts, tributyl phosphate is 1 part, tetraisopropyl titanate is 0.5 parts, polyethylene glycol (800) is 0.1 parts , each in moles of substance.

[0050] First weigh 42.6g (0.2mol) of aluminum ethylene glycol, 8g (0.2mol) of sodium hydroxide, and 124g (2mol) of ethylene glycol and place them in the reactor, and stir and react for 1 hour to become an intermediate solution. Add 28g (0.1mol) of tetraisopropyl titanate, 53.2g (0.2mol) of tributyl phosphate, 16g (0.02mol) of polyethylene glycol (800), and stir the reaction for 1 hour at 170°C, remove A small molecule with a low boiling point becomes a stable composition solution C after cooling to room temperature.

[0051] Preparation of PET

[0052] In the reactant 500g terephthalic acid (PTA), 260g ethylene glycol (EG) and barium sulfate (based on the amount of polyester produced, the amount added is 2500×10 -6 ), adding composition solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com