Patents

Literature

34results about How to "Low yellowness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

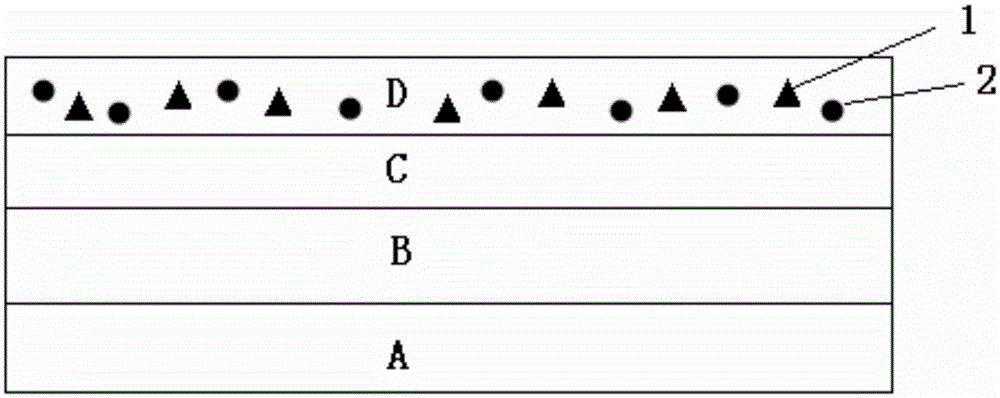

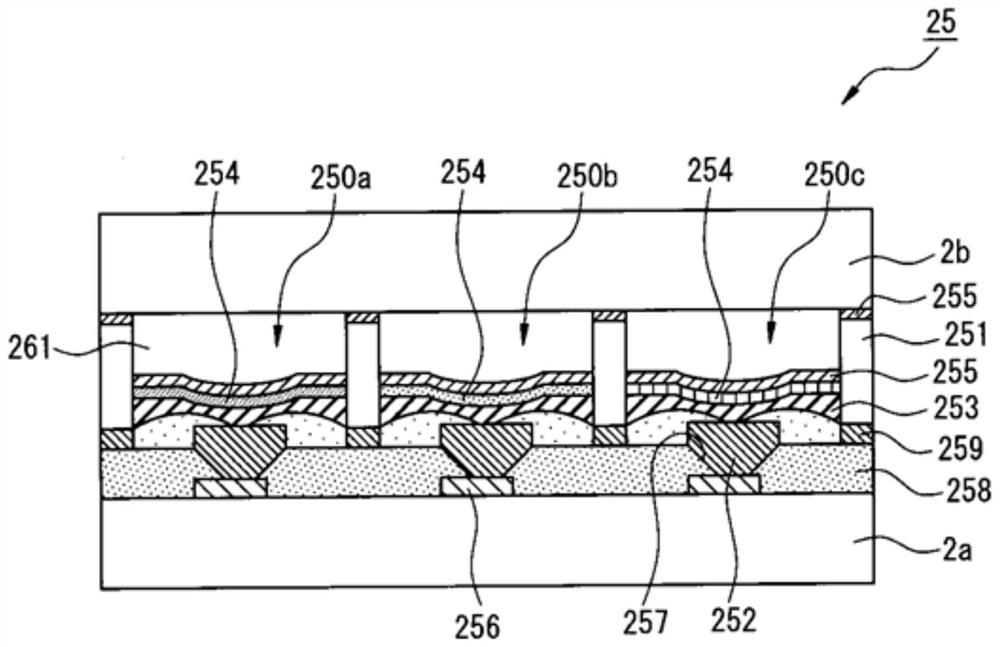

Resin precursor, resin composition containing same, polyimide resin membrane, resin film, and method for producing same

ActiveCN106661326AGood adhesionNo particlesSynthetic resin layered productsSolid-state devicesOrganic solventAbsorbance

Provided is a resin composition including a polyimide precursor that has exceptional adhesiveness to glass substrates and that does not generate particles during laser detachment. A resin composition containing (a) a polyimide precursor, (b) an organic solvent, and (d) an alkoxysilane compound, wherein the resin composition shows polyimide obtained by imidation of the (a) polyimide precursor after application of the resin composition to the surface of a support, the residual stress with the support is from -5 MPa to 10 MPa, and the 308 nm absorbance of the (d) alkoxysilane compound when made into a 0.001 mass% NMP solution is from 0.1 to 0.5 at a solution thickness of 1 cm.

Owner:ASAHI KASEI KK

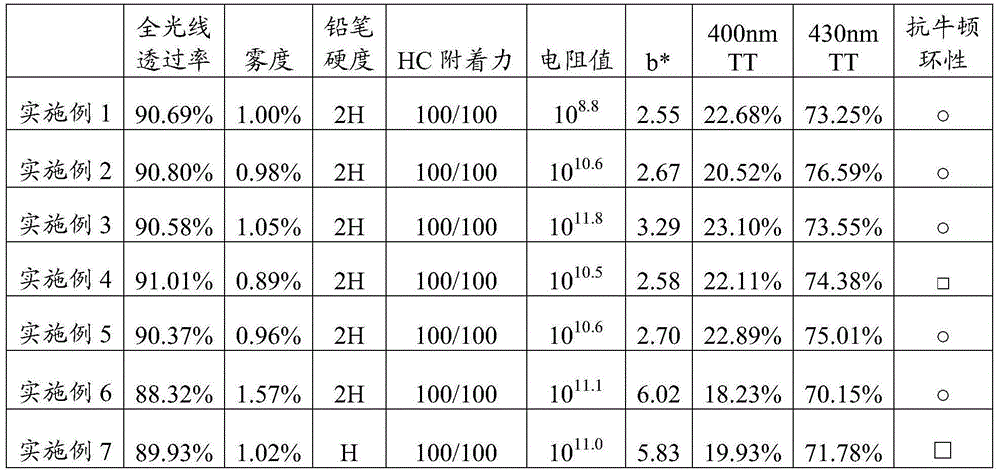

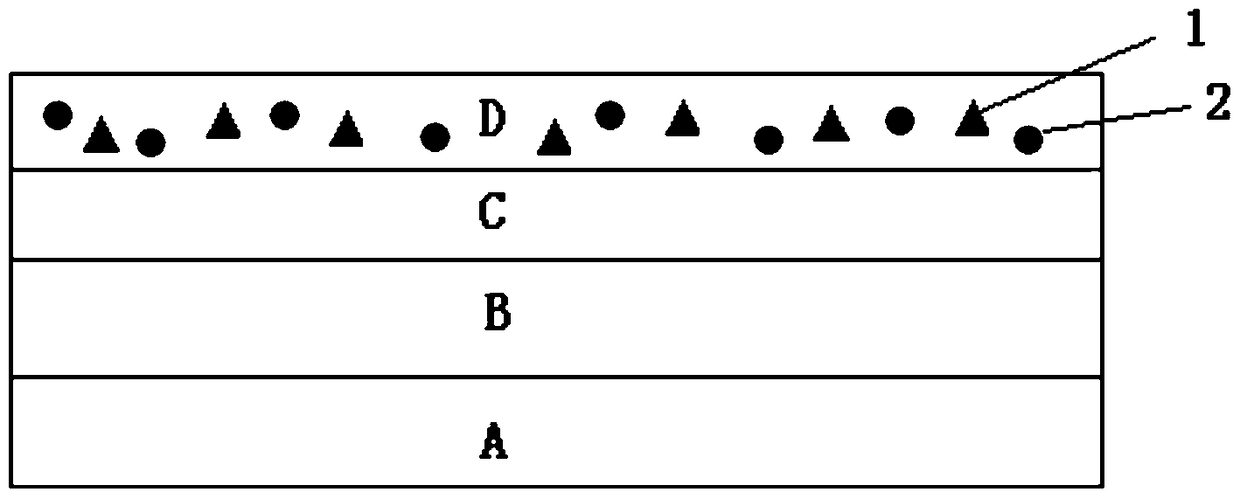

Multifunctional screen protection film

ActiveCN105058929AHigh hardnessImprove adhesionSynthetic resin layered productsAntistatic agentBiochemical engineering

The invention provides a multifunctional screen protection film which sequentially comprises a release film layer, an optimal adhesive layer, a base material layer and a multifunctional layer, wherein the optical adhesive layer is arranged on the release film layer, the base material layer is arranged on the optical adhesive layer, and the multifunctional layer is arranged on the base material layer and comprises an anti-blue-light agent, an antistatic agent and anti-newton's-ring coating resin. The multifunctional screen protection film has antistatic, anti-blue-light and anti-newton's-ring functions and has better anti-blue-light performance and the lower yellowing degree, so that the comfort degree of the screen protection film in use is increased. Besides, the multifunctional screen protection film is high in hardness, large in adhesive force, simple in structure, easy to produce and low in cost.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

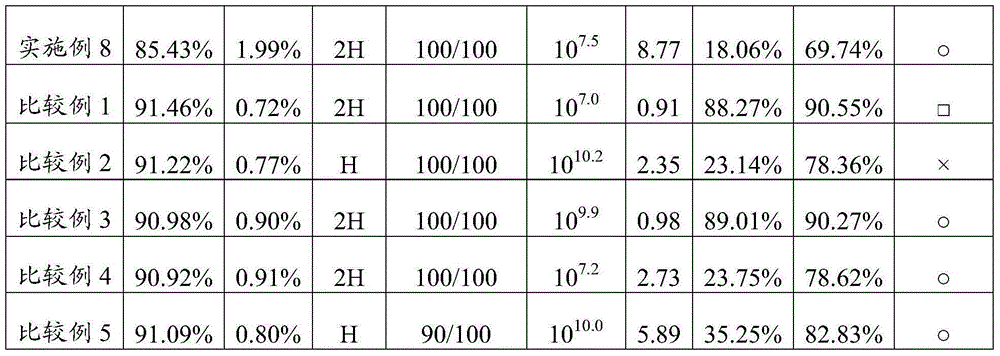

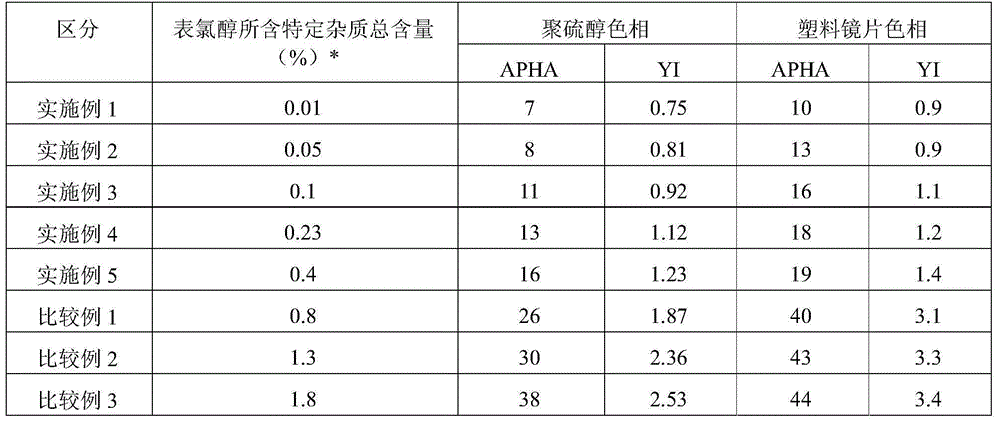

Method for producing polythiol compound for optical materials and composition comprising same for optical materials

ActiveCN104066716AInhibit coloringLow yellownessThiol preparationSulfide preparationChemical compound2-Mercaptoethanol

The present invention relates to a polythiol compound for optical materials exhibiting desirable characteristics from a coloring perspective, a composition comprising same for optical materials, and a method for producing optical materials. The present invention provides a method for producing a polythiol compound for optical materials which reacts epichlorohydrin compound having total impurities content of less than 0.5 wt% and 2-Mercaptoethanol. The present invention allows obtaining a polythiol compound exhibiting suppressed coloration, and by using same, allows obtaining a urethane group exhibiting suppressed coloration, low yellowness and good coloring. The polythiol compound according to the present invention can be used in the production of a variety of optical materials such as a urethane group, and optical lenses having good coloring, obtained by means of the present invention, can replace existing lenses and be widely used in diverse fields, particularly as lenses for glasses, polarized lights and cameras.

Owner:MITSUI CHEM INC

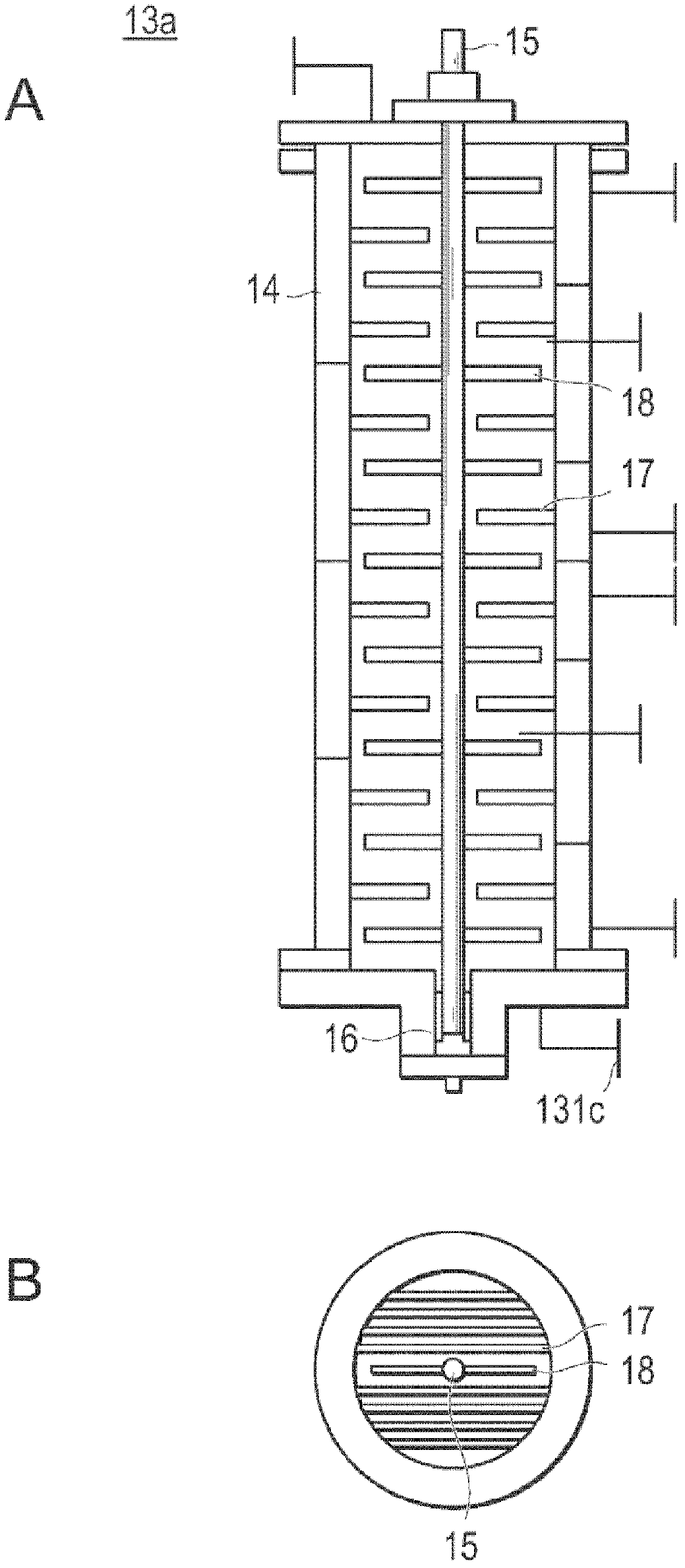

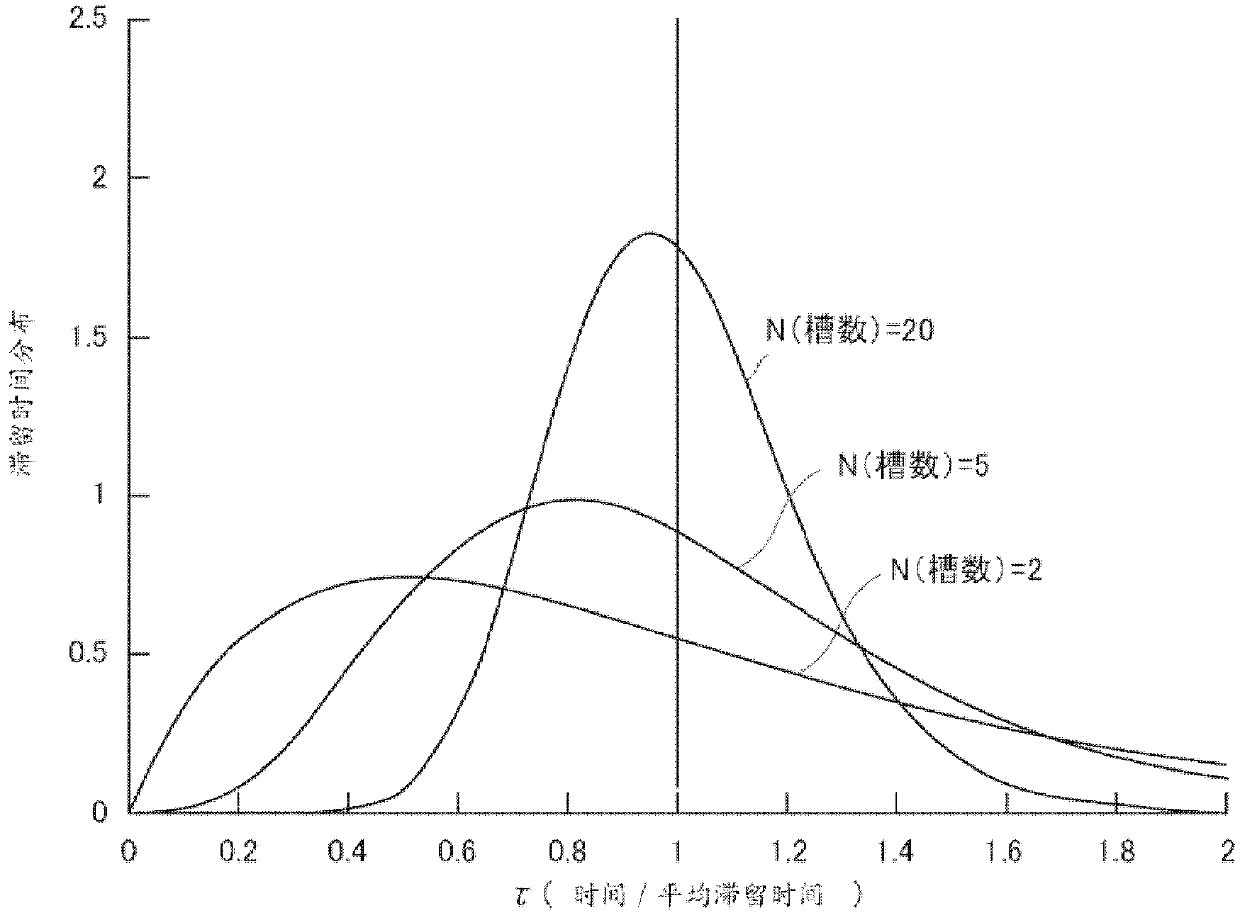

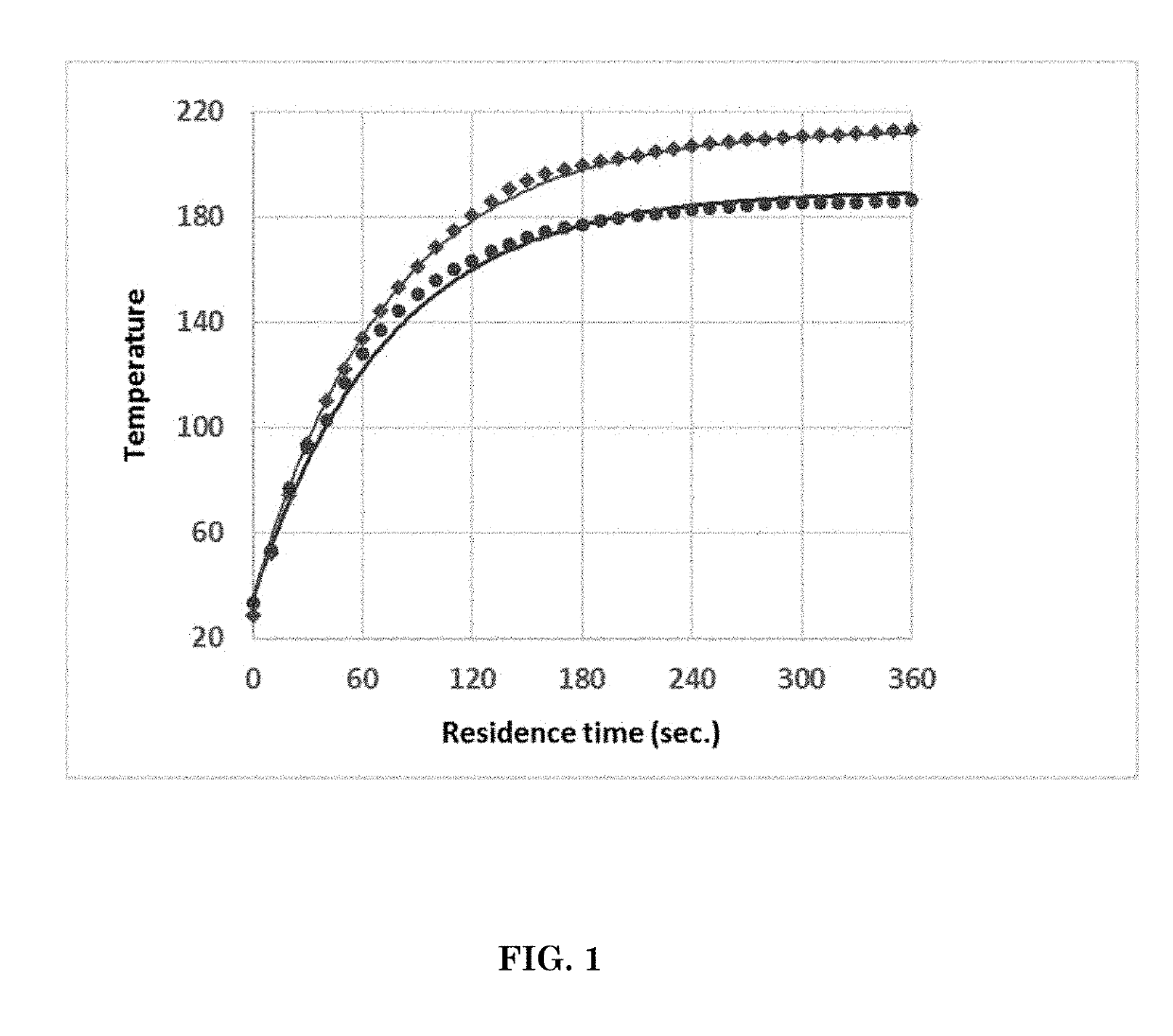

Process for production of polylactic acid

ActiveCN102459401ALow costHigh molecular weightChemical/physical/physico-chemical processesPolylactic acidImpulse response

Provided is a process for the production of polylactic acid, by which a high-molecular-weight polylactic acid can be obtained at a low cost. A process for the production of polylactic acid which comprises polymerizing molten lactide using at least one plug flow reactor that has a Xi(t) value of 0.3 or smaller as calculated from numerical formula (1) [wherein E(t) is a residence time distribution function found by an impulse response method with a starch syrup having a viscosity of 3Pas, and t is the ratio of elapsed time (Theta) to mean residence time (Theta0)].

Owner:UHDE INVENTA FISCHER

Reducing and bleaching composition for pulp from decoloured waste paper and its bleaching method

InactiveCN1351211AReduce invalid decompositionImprove bleaching efficiencyPulp bleachingSodium carbonateSolvent

A reducing and bleaching composition for decoloured waste pulp is prepared from sodium dithionite (5-15 wt.%), chelating agent (1.25-15), sodium carbonate or sodium hydroxide or their mixture (0.25-3) and water (79.5-93.5) through uniform mixing. Its bleaching method features that the stabilizer and said composition are cooperated, and the oil or solvent not dissolved in water is added to isolate air, so improving the stability of bleaching liquid, reducing consumption of sodium dithionite and improving bleaching effect. Its advantages include less damage to strength and opaqueness of paper fibres, less corrosion to pipeline, less pollution and low cost.

Owner:SOUTH CHINA UNIV OF TECH

Reducing and bleaching composition for pulp from decoloured waste paper and its bleaching method

Owner:SOUTH CHINA UNIV OF TECH

Polymethacrylate composition and optical device made therefrom, and display apparatus

ActiveCN110016195AImprove heat resistanceGood thermal stabilityOptical elementsPolymer scienceAcrylate ester

A polymethacrylate composition, an optical device made therefrom, and a display apparatus are provided. The polymethacrylate composition includes 50 to 85 parts by weight of methacrylate series polymer, and 15 to 50 parts by weight of styrene series-maleic anhydride series copolymer. The methacrylate series polymer includes methacrylate series monomer unit and acrylate series monomer unit and hasa weight average molecular weight (Mw) in a range between 20,000 and 200,000. A range of molecular weight distribution index (PDI) of the styrene series-maleic anhydride series copolymer is from 1.5 to 2.05. The styrene series-maleic anhydride series copolymer includes 76.5wt%-90wt% of styrene series monomer unit, 10wt%-23.5wt% of maleic anhydride series monomer unit, and 0-13.5wt% of second copolymerizable monomer unit.

Owner:CHI MEI CORP

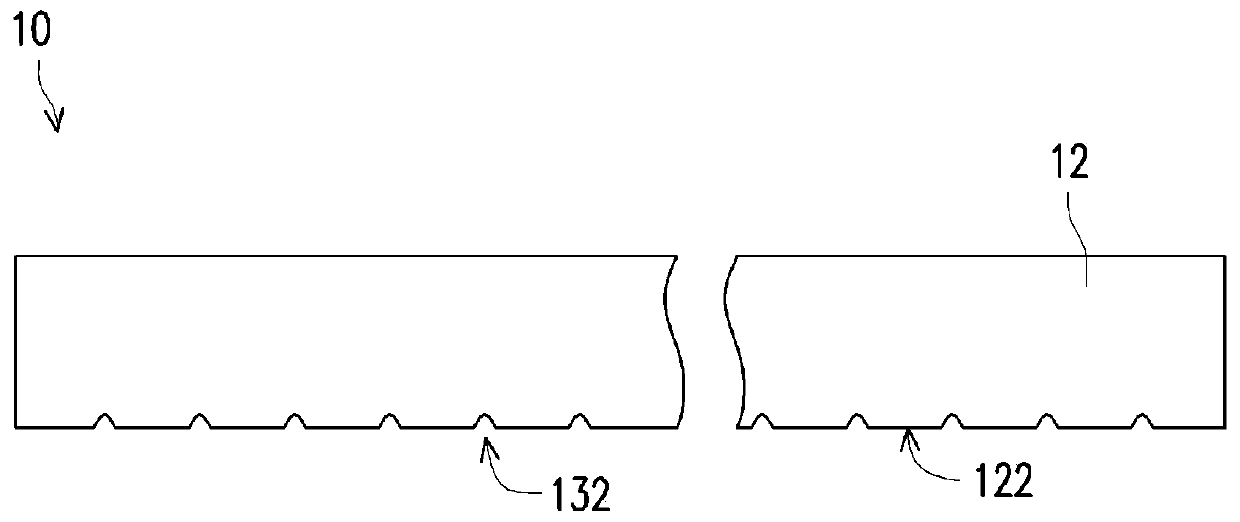

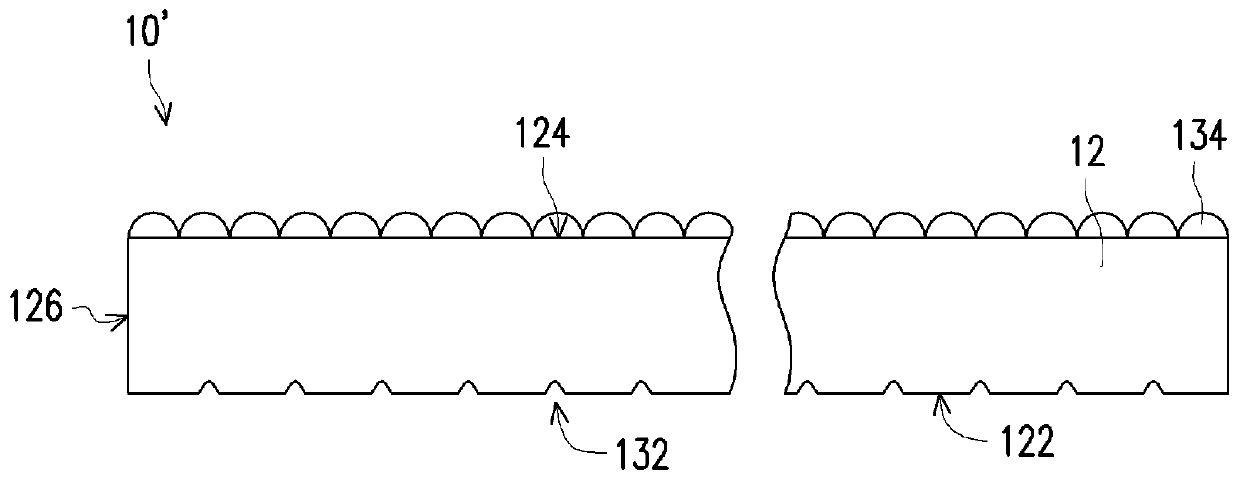

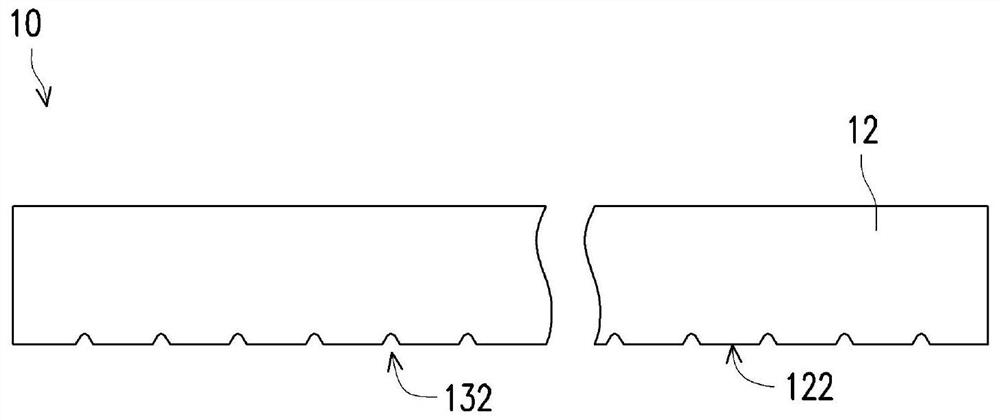

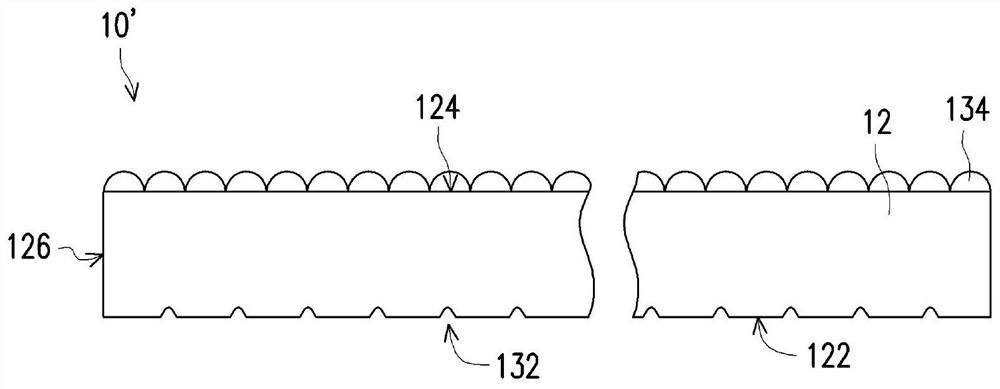

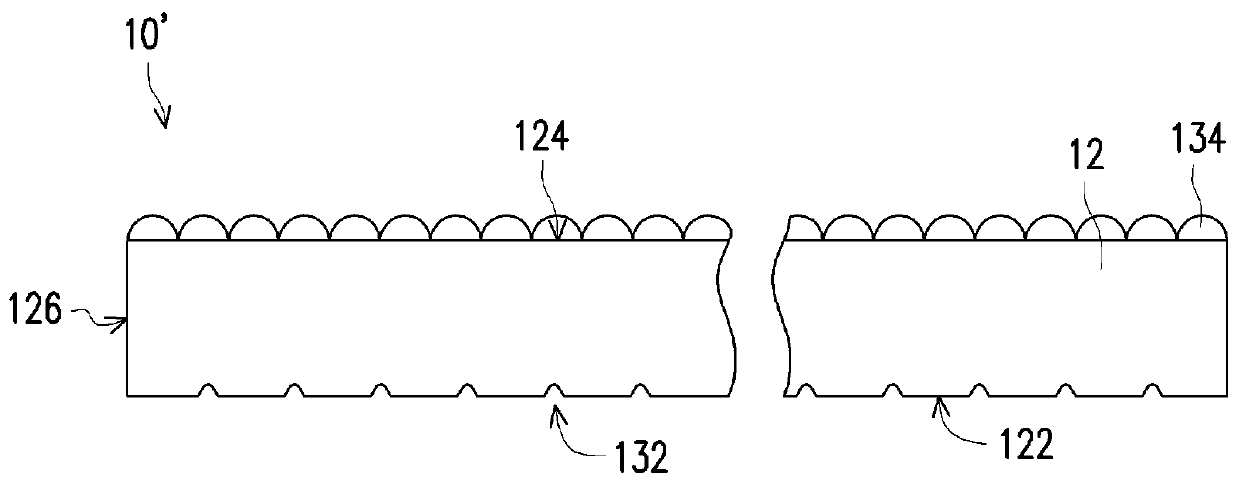

Optical film and optical member using optical film

The invention proivdes an optical film being capable of reducing yellow degree. The optical film is described in such way: for a sunken part satisfying the following conditions (1) and (2), the number of the sunken parts is lower than 4 per 10000 [mu]m<2> on a single surface and a back surface of the optical film. (1) the depth of the sunken part is more than 200 nm; (2) the diameter of the part, which is higher than 200 nm in depth, of the sunken part is more than 0.7 [mu]m.

Owner:SUMITOMO CHEM CO LTD

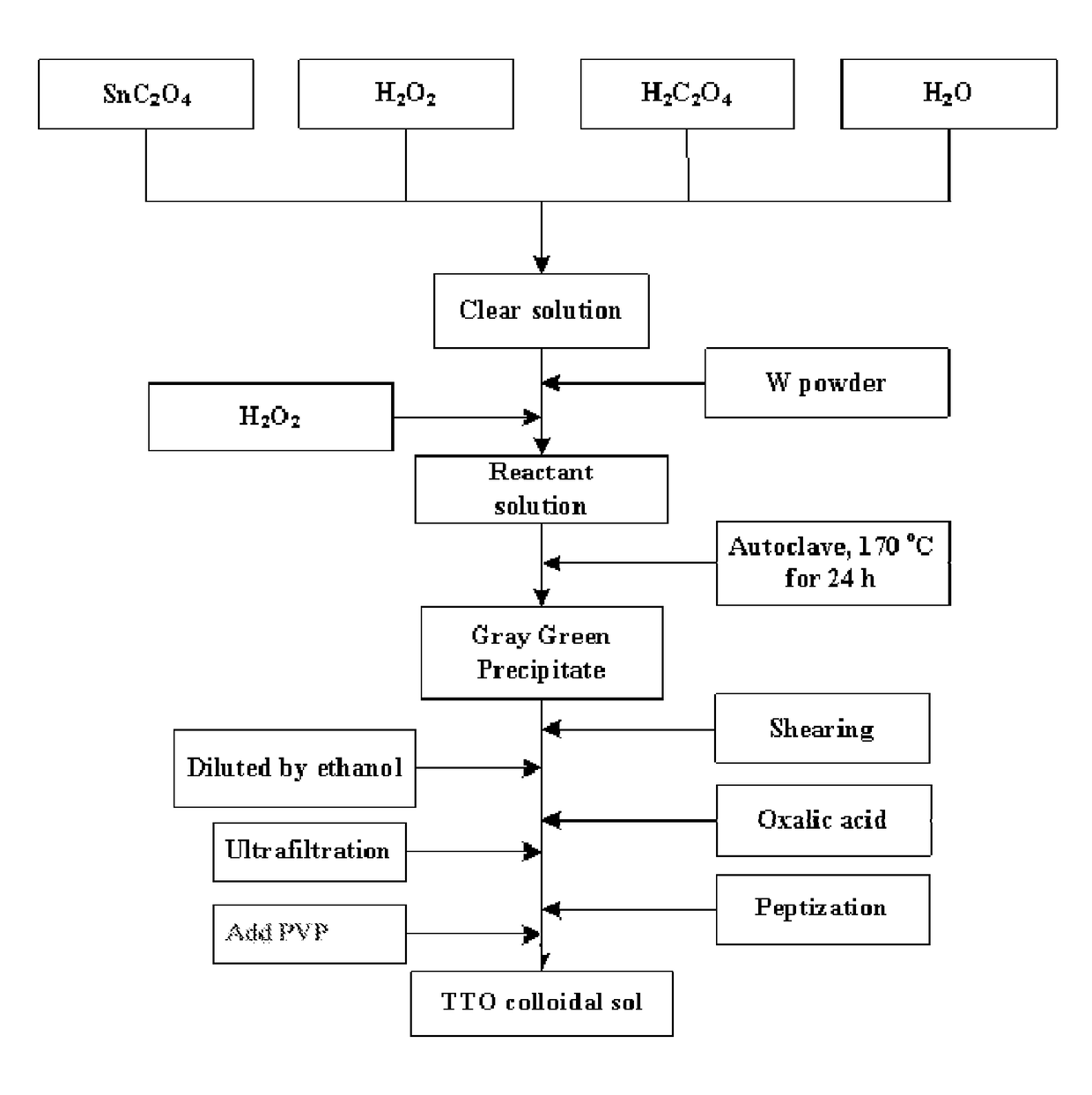

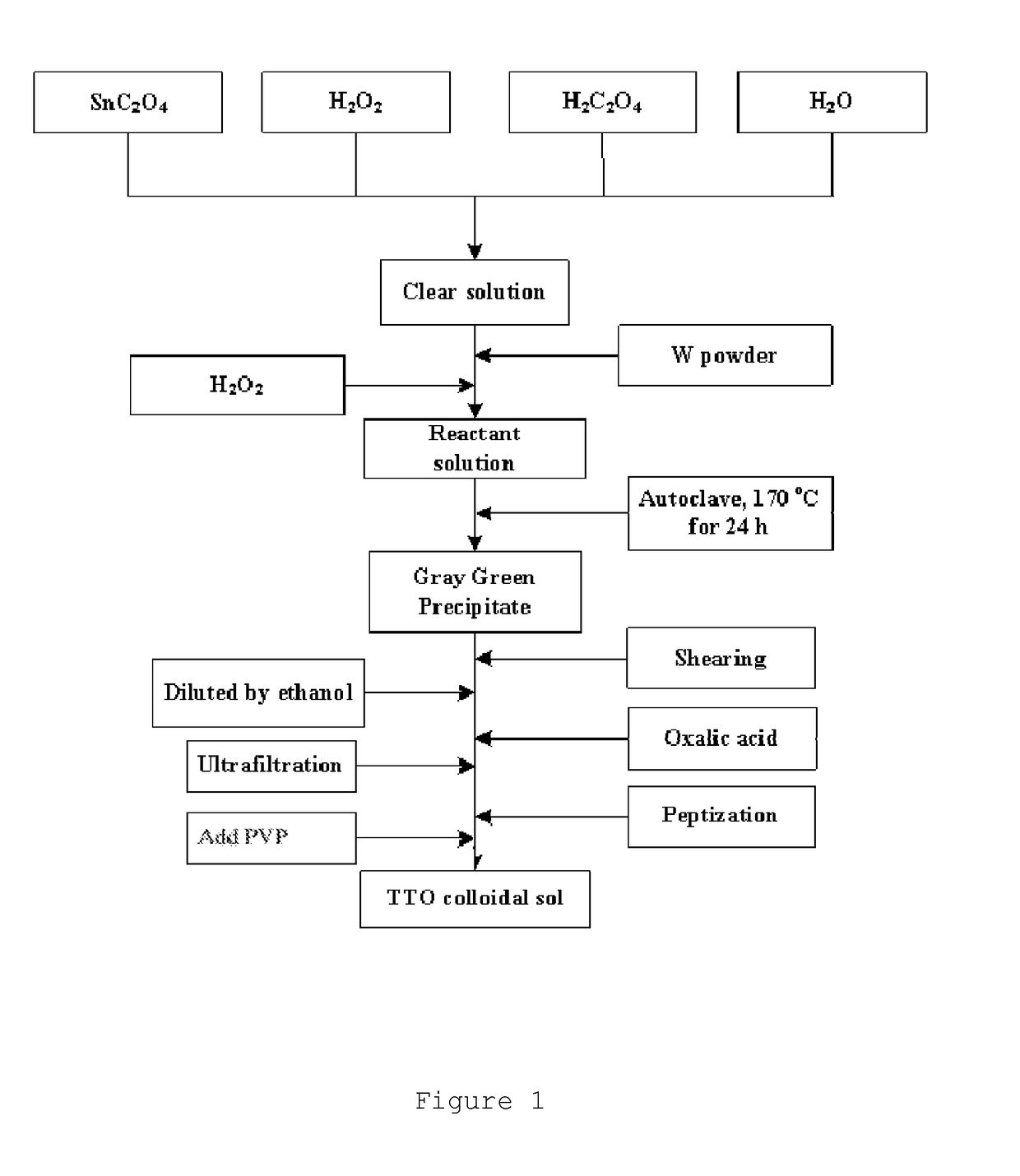

Tungsten-doped stannic oxide colloidal suspension and method for preparing the same

InactiveUS20180171158A1Good performanceLow yellownessElectrically-conductive paintsTin oxidesChemistryTungsten

Owner:SHANGHAI UNIV +1

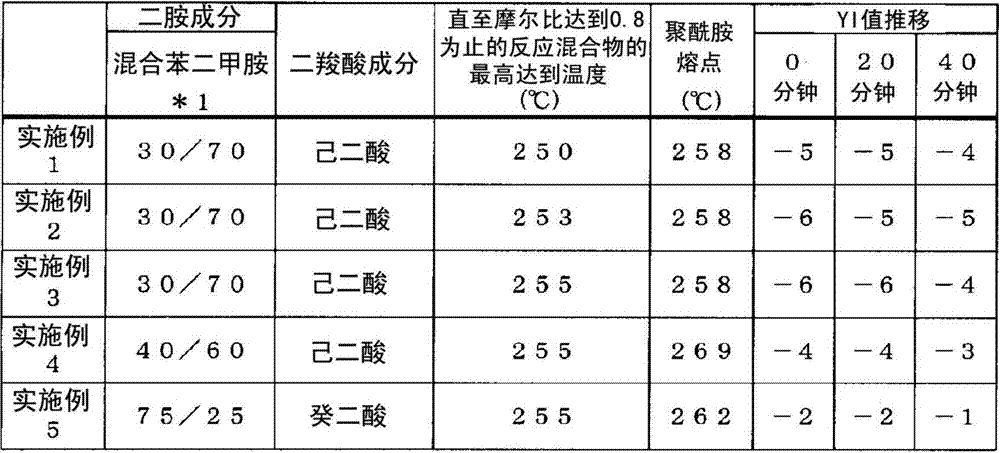

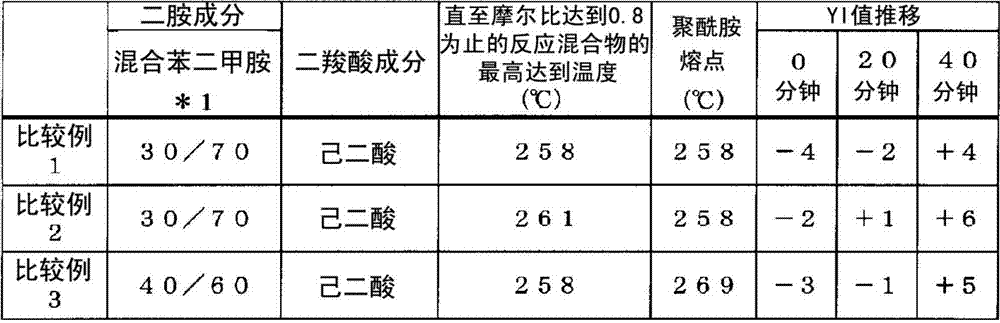

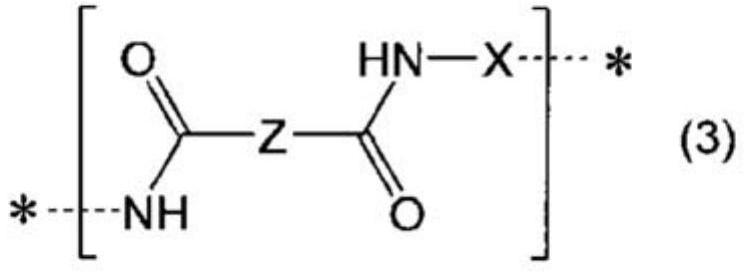

Manufacturing method of polyamide

The present invention provides a method for producing polyamide having improved color tone and favorable quality polyamide, which is characterized in that mixed xylylenediamine containing p-xylylenediamine is used as a diamine component together with two In the method of producing polyamide having a melting point of 255°C or higher by polycondensation of carboxylic acid components using a batch reaction device, the reaction mixture is heated to a temperature above the melting point while maintaining a molten state under a pressure of 0.1 MPaG or higher. When adding the diamine component dropwise to the molten dicarboxylic acid component, keep the temperature of the reaction mixture below 255°C until the molar ratio of the reaction mixture (diamine component / dicarboxylic acid component) reaches 0.8, and when the dropwise addition is completed, The temperature of the reaction mixture is above the melting point of the aforementioned polyamide.

Owner:MITSUBISHI GAS CHEM CO INC

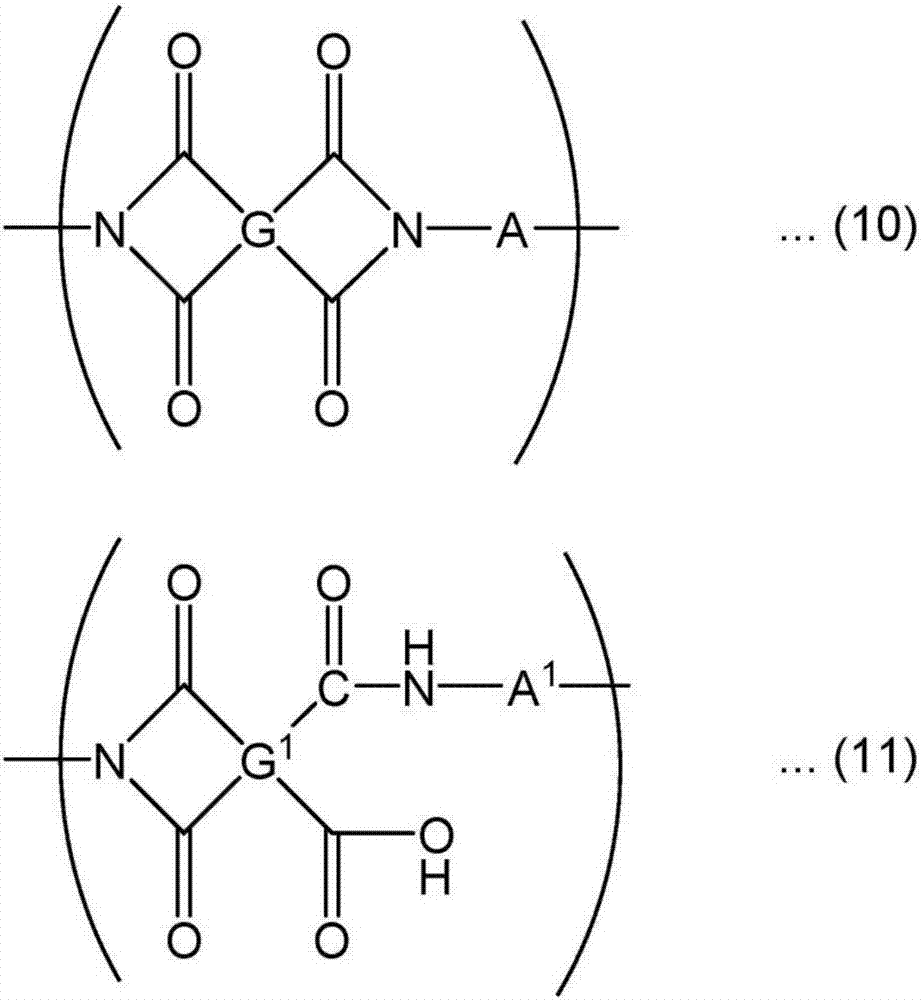

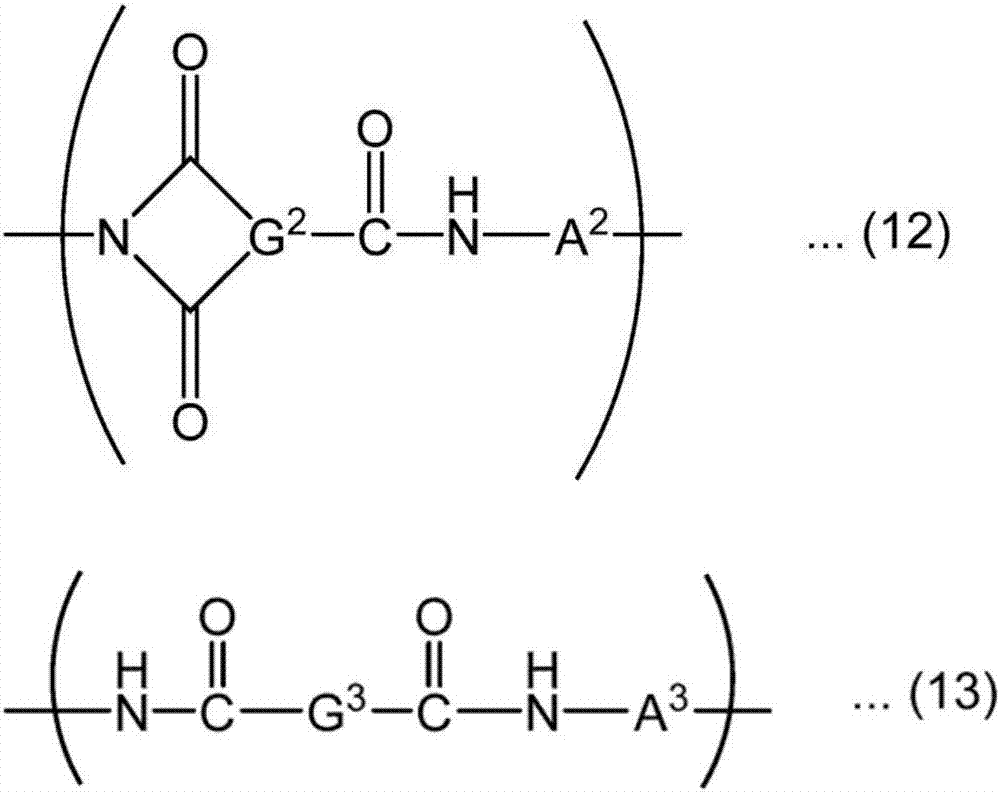

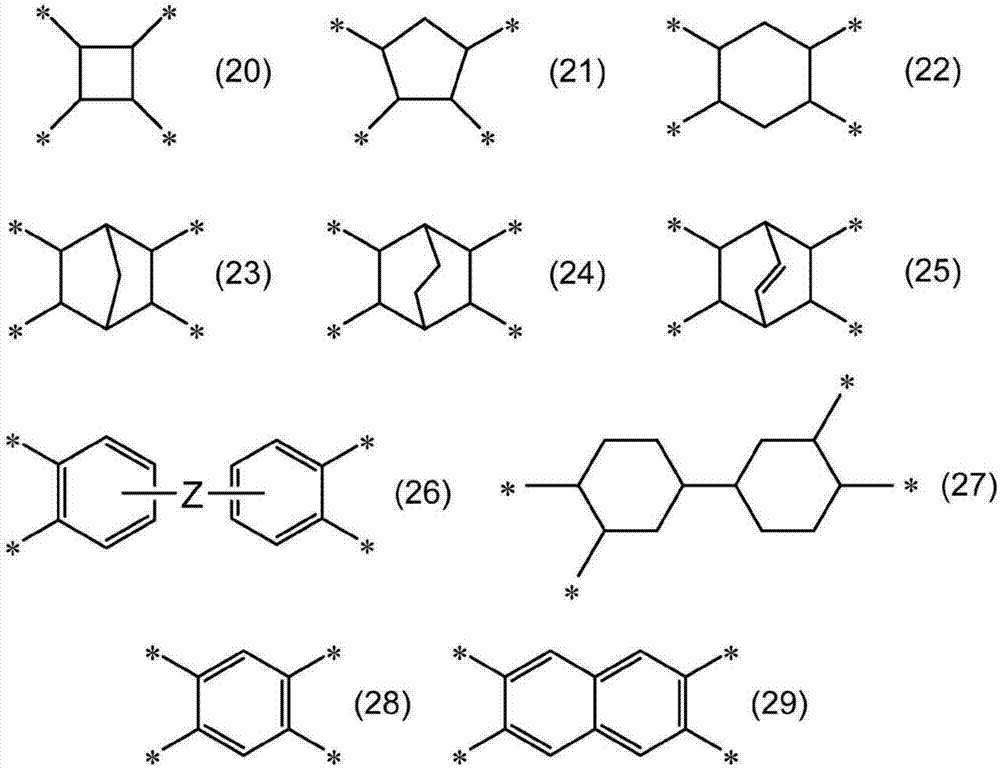

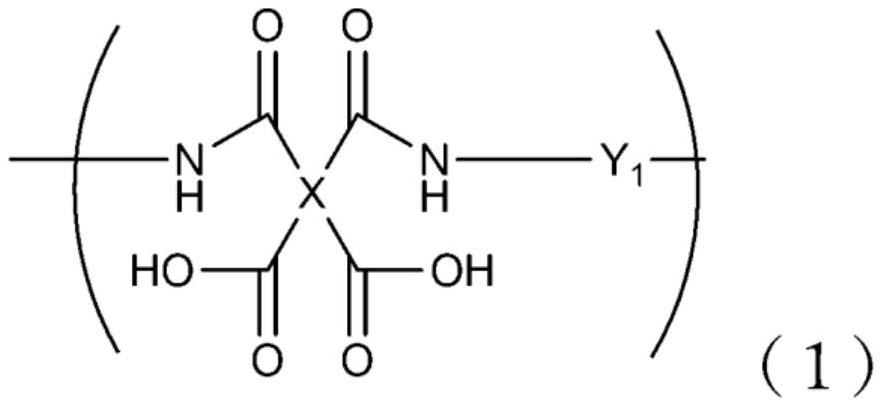

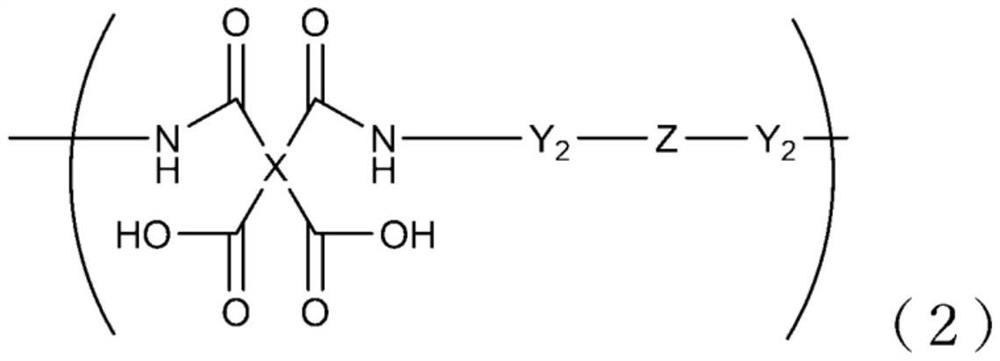

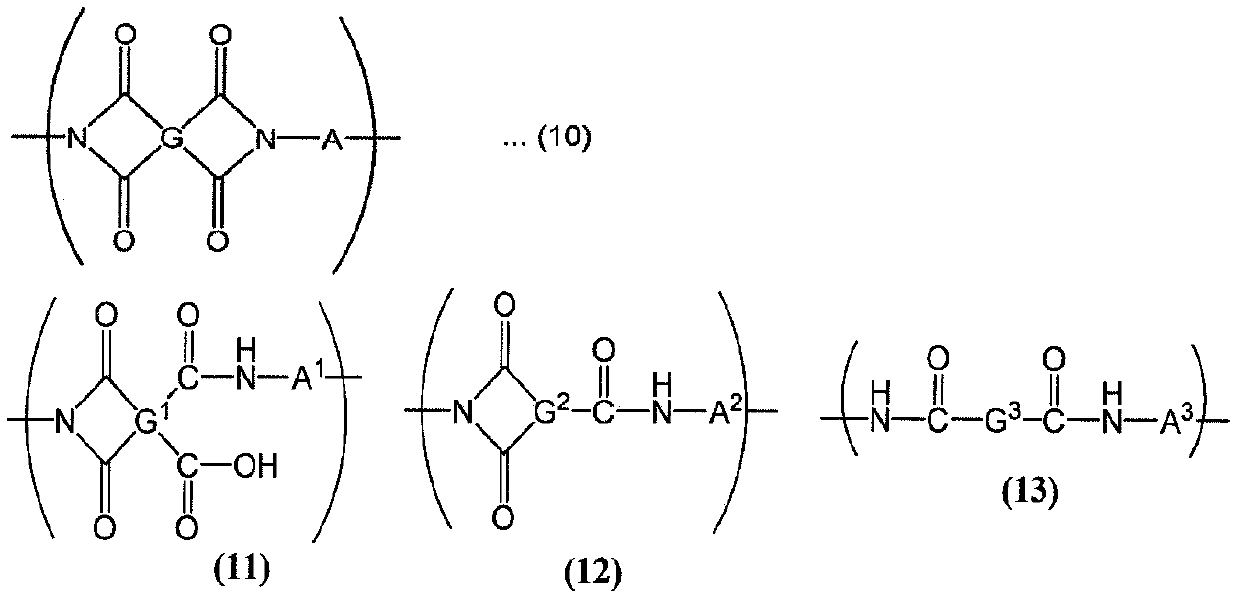

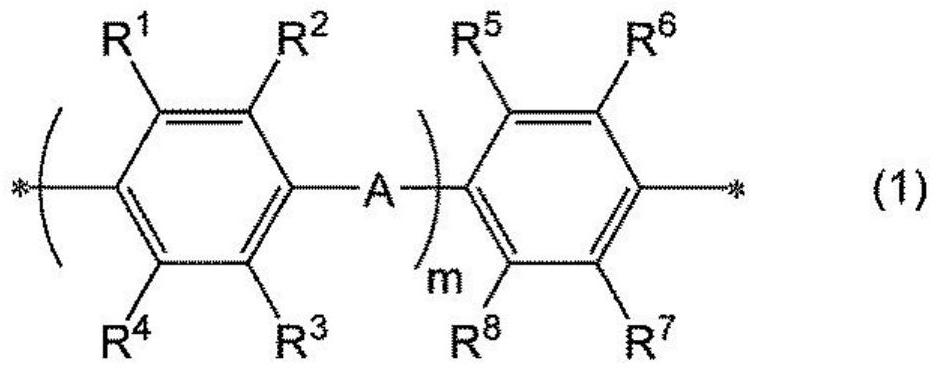

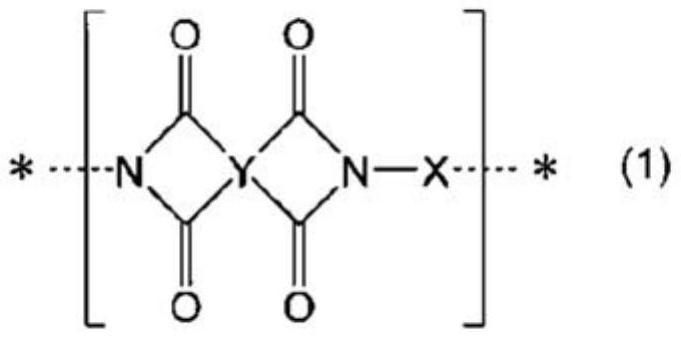

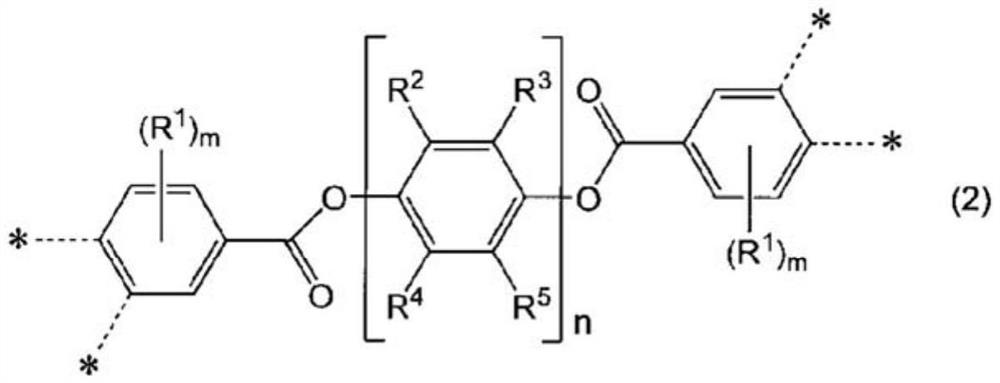

Polyimide precursor, resin composition comprising same, polyimide resin film, resin film, and method for producing same

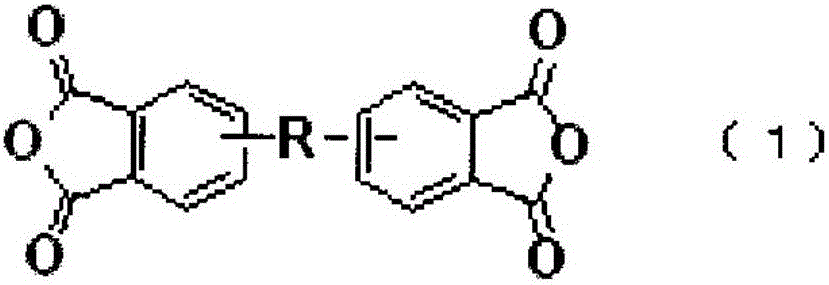

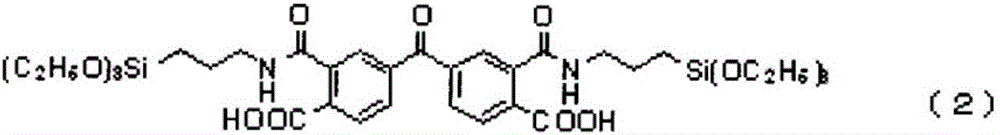

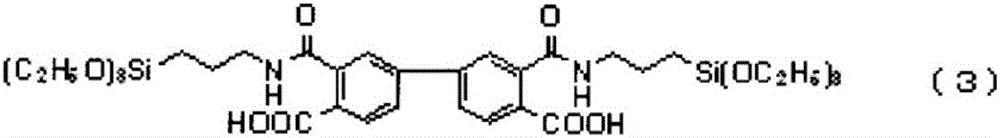

PendingCN113549217AReduce warpageLow yellownessSolid-state devicesSemiconductor/solid-state device manufacturingImidePolymer science

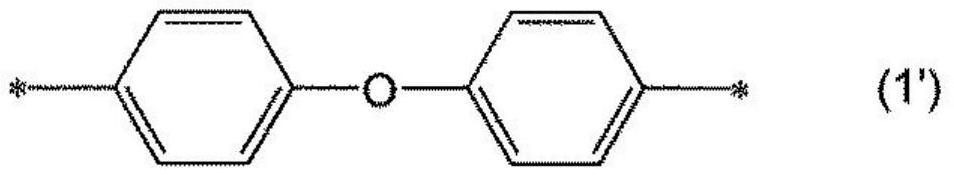

A polyimide precursor, a resin composition comprising the same, a polyimide resin film, a resin film, and a method for manufacturing the same. Provided are: a polyimide resin film which has low residual stress, little warpage, low yellowness (YI value) at high temperatures (particularly 430 DEG C or higher), low haze (Haze value), and excellent laser peelability from a substrate; and a method for producing the polyimide resin film. A polyimide precursor comprising: (a1) a structural unit L represented by general formula (1); and (a2) a structural unit M represented by general formula (2). The ratio of the amount of the structural unit M to the total amount of the structural unit L and the structural unit M is 0.005-0.5 mol%.

Owner:ASAHI KASEI KK

Optical film

PendingCN110412665ALow yellownessHigh elastic modulusPolarising elementsNon-linear opticsChemistryElastic modulus

An object of the present invention is to provide an optical film capable of simultaneously achieving low yellowness (ZI value) and high elastic modulus. The solution of the present invention is an optical film comprising a polyamideimide resin. When the cross section of the membrane was measured by time-of-flight secondary ion mass spectrometry, the intensity ratio (A / B) of the methoxyl ion intensity (A) to the silicon ion intensity (B) was greater than or equal to 0.02.

Owner:SUMITOMO CHEM CO LTD

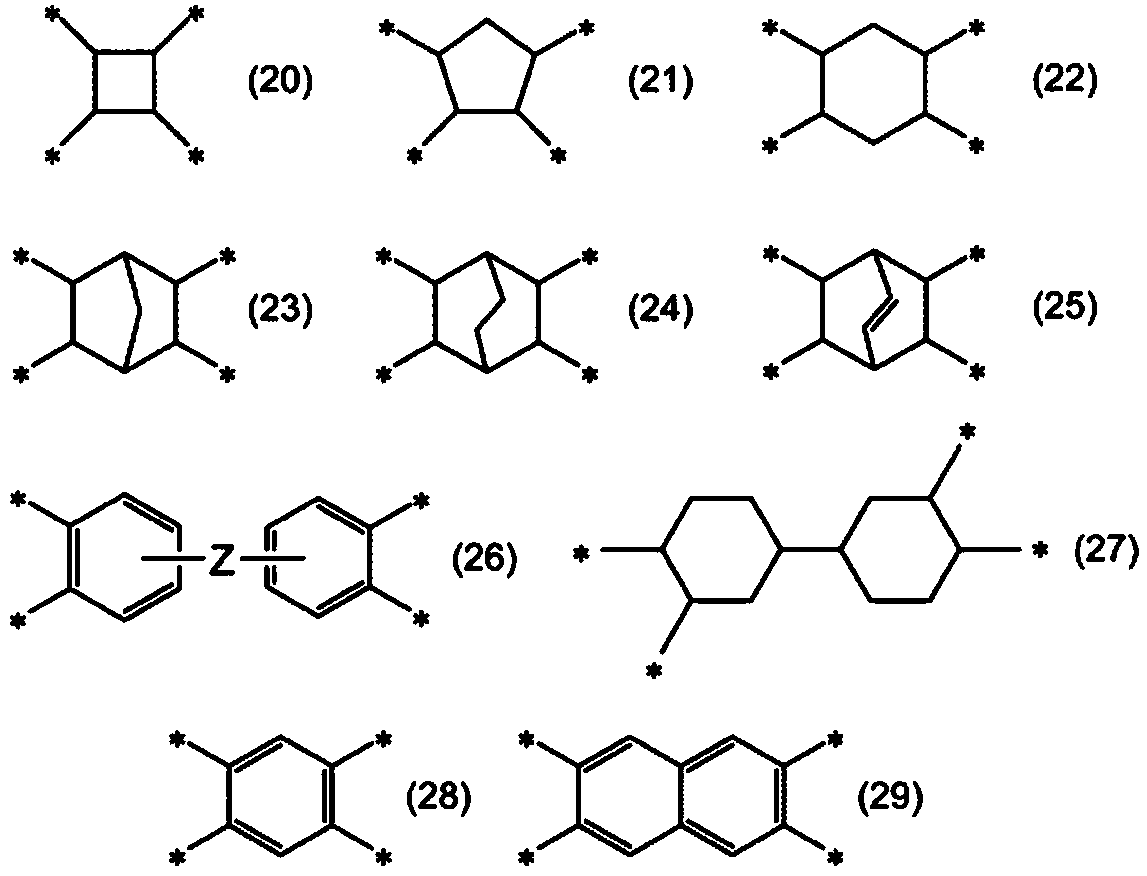

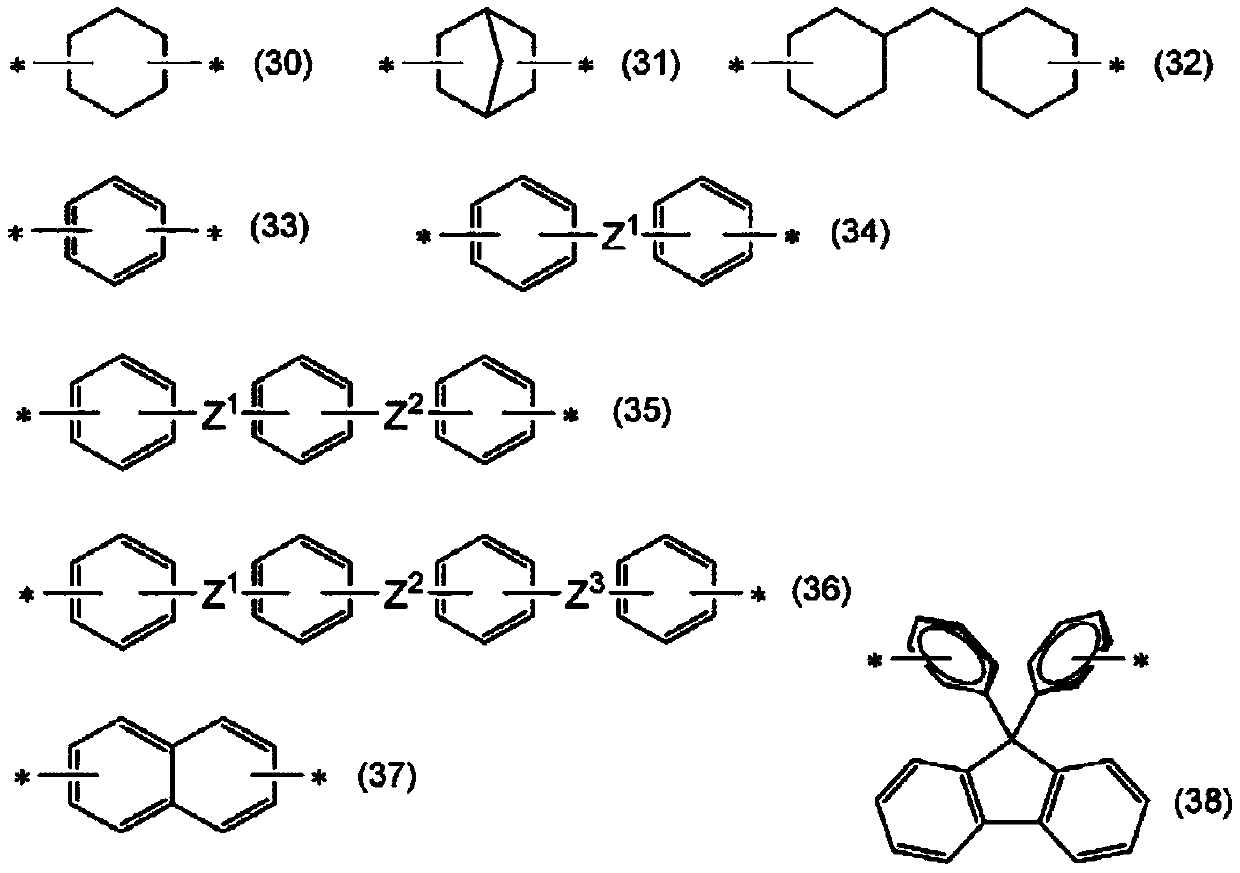

Anti-glare film, method for producing same, and use thereof

PendingCN111433640AGuaranteed anti-glareLow yellownessDiffusing elementsLayered productsPolymer scienceDiffuse reflection

Owner:DAICEL CHEM IND LTD

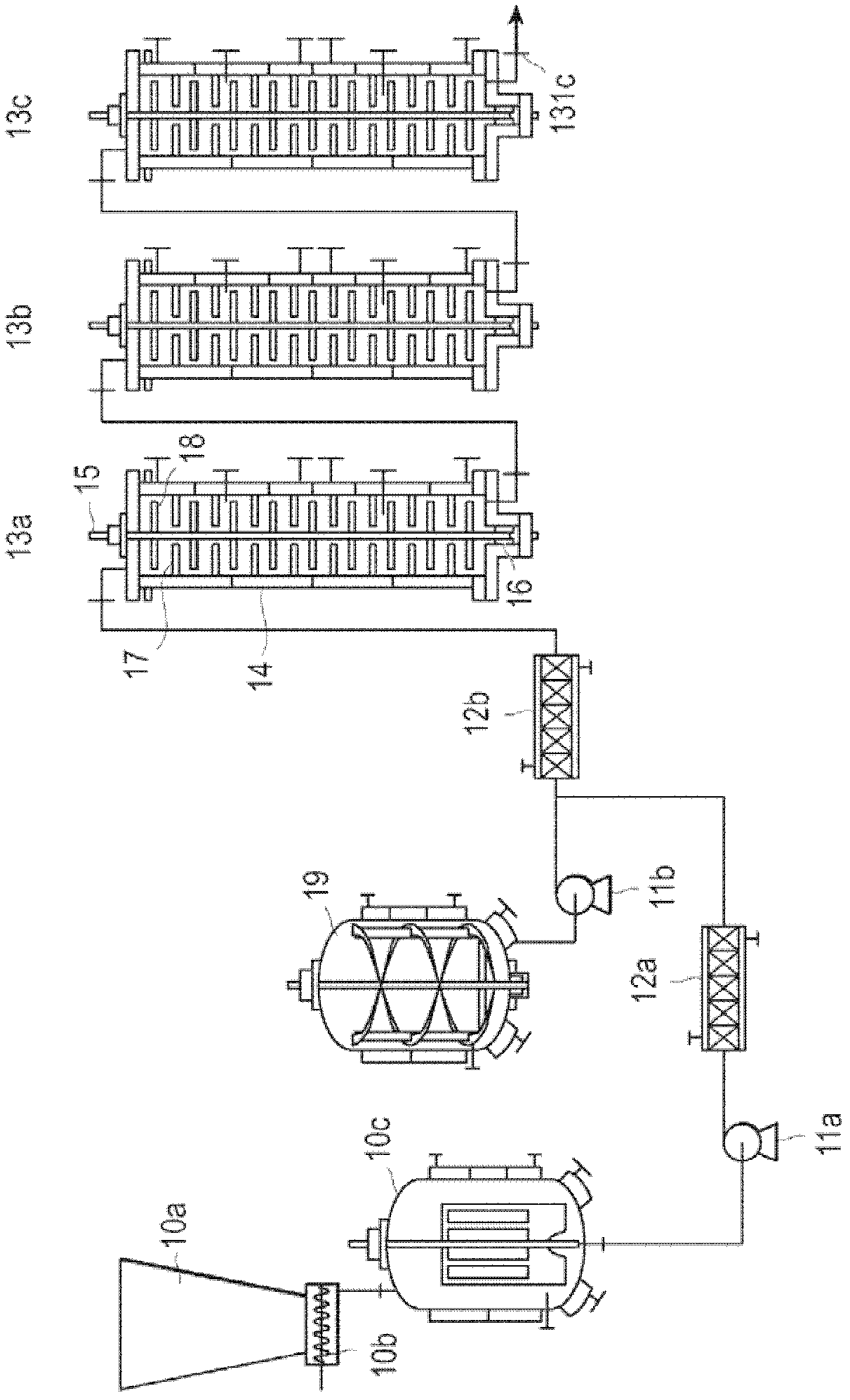

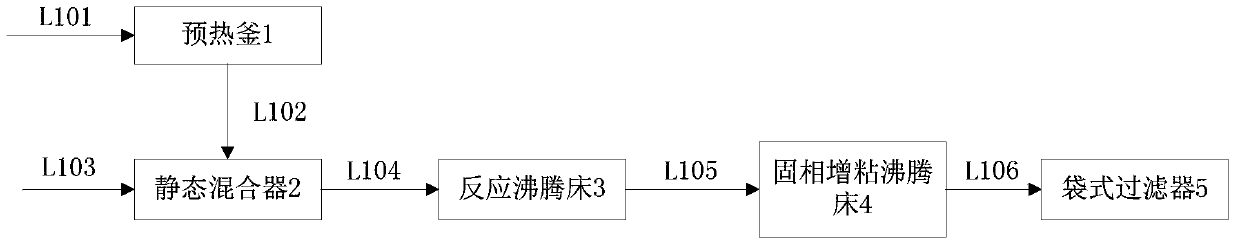

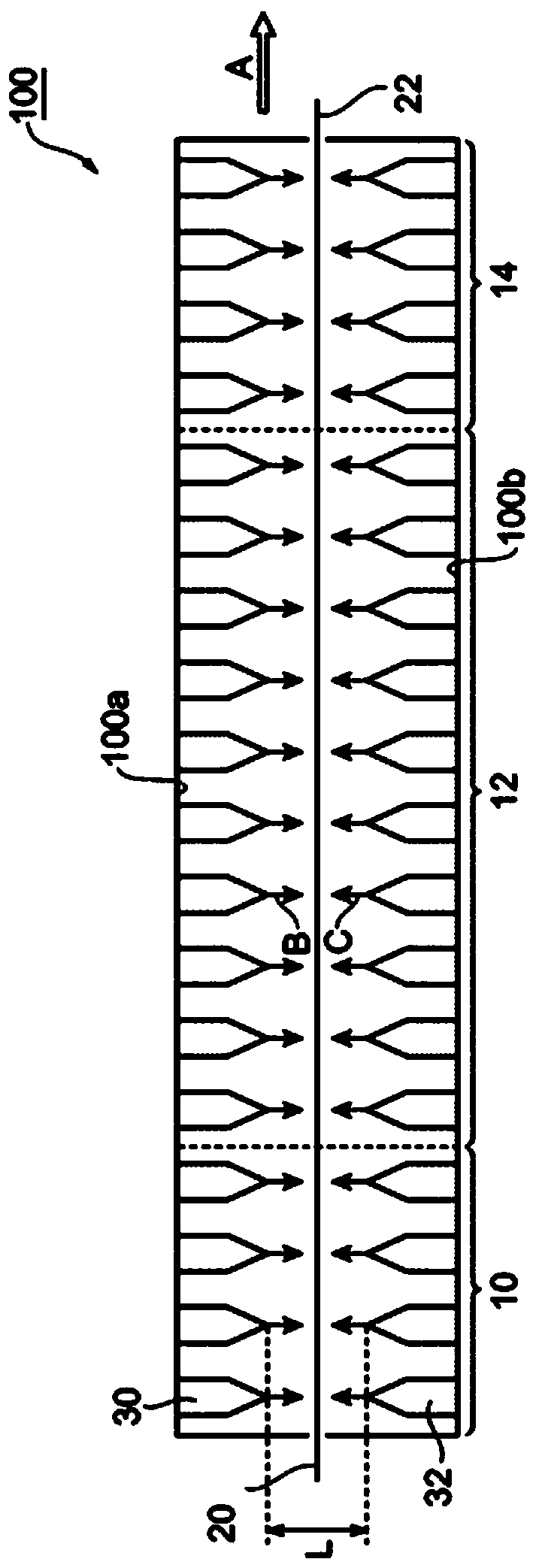

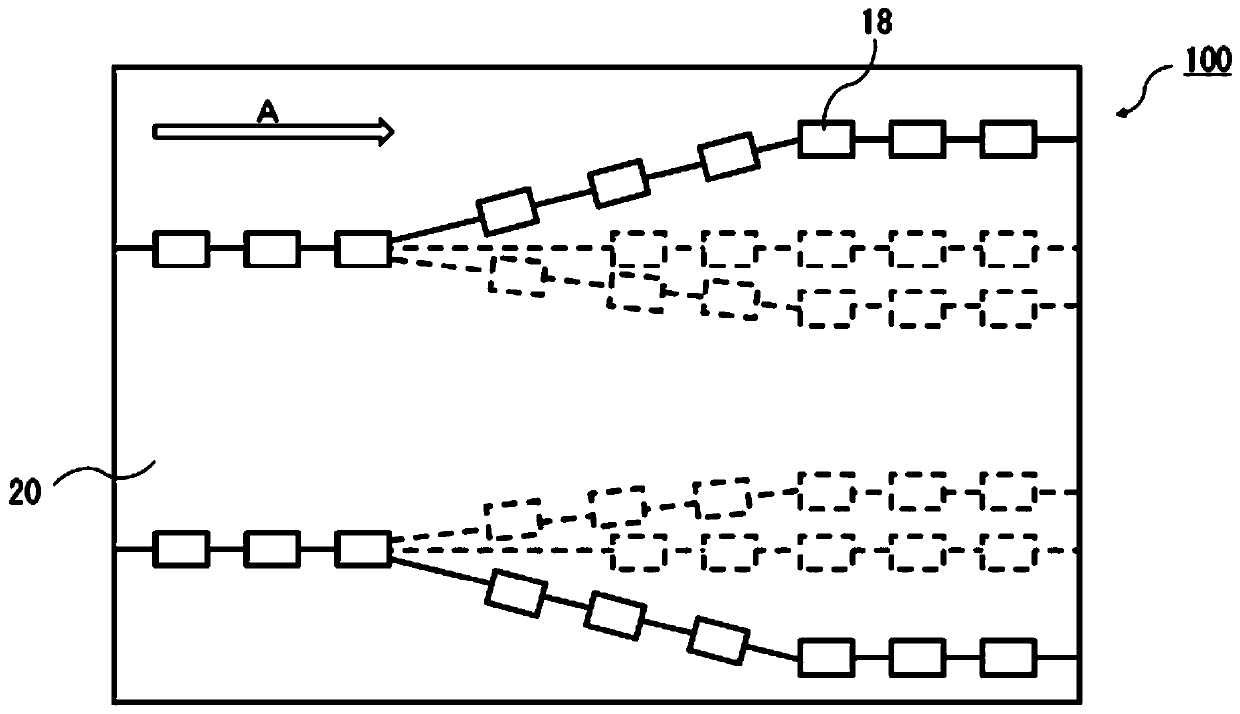

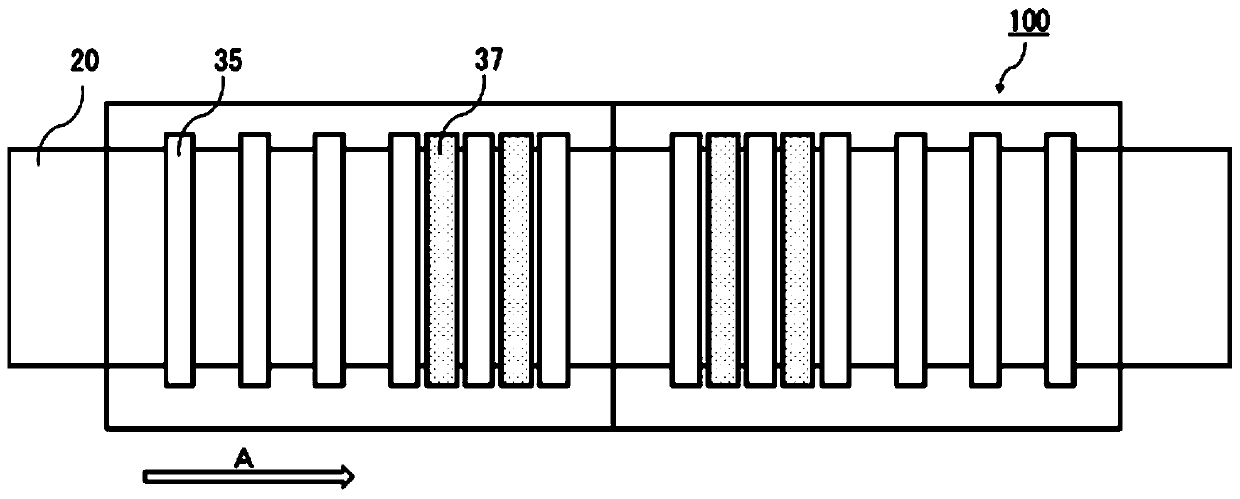

A device and process for preparing high molecular weight polyester by ring-opening polymerization of cyclic ester

ActiveCN106928437BThe implementation only recyclesRealize continuous productionPolyesterState of art

The invention relates to an apparatus and process for preparing high-molecular-weight polyester by ring-opening polymerization of a cyclic ester; the process comprises the steps of feeding raw cyclic ester (L101) into a preheating kettle, and melting to form first liquid (L102); dissolving a catalyst and a photoinitiator in a solvent to form second liquid (L103); adding both the first liquid (L102) and the second liquid (103) into static mixer (2), and mixing well to form third liquid (L104); feeding the third liquid to atomizing nozzle (6) at the top of a reaction boiling bed (3), atomizing, spraying into the reaction boiling bed (3), reacting under an inert carrier gas to obtain first solid (L105), feeding the first solid to solid tackifying boiling bed (4), performing tackifying reaction to obtain second solid (L106), feeding the second solid to a bag filter (5), and isolating to obtain the product, the high-molecular-weight polyester. Compared with the prior art, the apparatus and process can provide continuous production and high production efficiency, and the obtained product has high molecular weight and low yellow value.

Owner:PUJING CHEM IND SHA

Resin film and manufacturing method thereof

PendingCN110628057ADefect suppressionExcellent optical propertiesInput/output processes for data processingIdentification meansPolymer scienceOptical property

The present invention addresses the problem of providing: a resin film which has optical properties required for a front panel, while being suppressed in defects such as damage due to rattling of thefilm during production; and a method for producing the resin film. The invention provides a resin film. The resin film contains at least one of a polyimide resin or a polyamide resin, and the center point in the width direction of the film is set as TDc; the in-plane phase difference value R (TDc) of TDc and the in-plane phase difference value R (TD80) of TD80, which are measured at a wavelength of 590 nm, satisfy formula (1), where TD80 is the point of 80% of the length from the center point in the width direction to the end portion with the center point being 0%. R (TDc) / R (TD80)>=0.35 (1).

Owner:SUMITOMO CHEM CO LTD

Multifunctional AMOLED screen protection film

InactiveCN107310209AWith anti-scratch functionWith anti-reflection functionSynthetic resin layered productsRubber layered productsModulation functionHardness

The invention discloses a multifunctional AMOLED screen protection film which comprises a PET structure unit. A releasing film layer is arranged on the upper surface of the PET structure unit, a silicone rubber layer is arranged on the upper surface of the releasing film layer, and a multifunctional layer is arranged on the upper surface of the silicone rubber layer. Compared with the prior art, a material having a color modulation function is added to a PET base material, the color modulation function is achieved, a functional film improving the color of an AMOLED screen is obtained, the multifunctional layer has an anti-scratching function, an anti-reflection function, an anti-static function and an anti-dazzle function, so that the AMOLED screen has better anti-blue-light performance and also has smaller yellowness, and the using comfort of the screen protection film is improved. In addition, the multifunctional AMOLED screen protection film is high in hardness, good in attachment, simple in structure, easy to manufacture and low in cost.

Owner:HEFEI HUIKE PRECISION DIE CO LTD

Polymethacrylate composition and its formed optical element and display device

ActiveCN110016195BImprove heat resistanceGood thermal stabilityOptical elementsPolymer sciencePolymethyl methacrylate

The invention provides a polymethacrylate composition and the formed optical element and display device. The polymethacrylate composition comprises 50 to 85 parts by weight of methacrylate polymers and its weight average molecular weight (Mw) is 20,000 to 200,000, and 15 to 50 parts by weight of styrene-based polymers. Anhydride-based copolymers and organic phosphorus compounds. The methacrylate polymer includes methacrylate monomer units and acrylate monomer units. The styrene-maleic anhydride copolymer comprises 76.5wt% to 90wt% of styrenic monomer units, 10wt% to 23.5wt% of maleic anhydride monomer units and 0 to 13.5wt% of the second Copolymerizable monomer units. The content of the organophosphorus compound ranges from 200ppm to 900ppm.

Owner:CHI MEI CORP

Method for producing oxymethylene copolymer

ActiveUS10954332B2Reduce generationYellowness of the molded articles is reducedPolymer scienceOxomethylene

A method for producing an oxymethylene copolymer which gives molded articles that are inhibited from emitting formaldehyde and can be reduced in yellowness is provided. In producing an oxymethylene copolymer, an effective polymerization initiator amount is regulated to a value within a given range, the amount being calculated from the amount of perchloric acid or a derivative thereof contained in the polymerization initiator and the amount of triethanolamine contained in all the monomers comprising trioxane and comonomers, which are starting materials for the copolymer.

Owner:MITSUBISHI GAS CHEM CO INC

Optical film and method for producing the same

ActiveCN110199210BHigh surface hardnessSufficient surface hardnessCoatingsOptical elementsImidePolymer science

The object of the present invention is to provide an optical film comprising a polyamide-imide resin, especially a polyamide-imide resin-containing optical film which can be suitably used as a front plate of a flexible display or the like, and which can improve surface hardness even under relatively low-temperature heating conditions. Optical film of imide resin. The present invention provides an optical film comprising a polyamide-imide resin having a peak of tan δ measured by DMA in a temperature range of 300 to 370° C. and having a YI value of 3 or less.

Owner:SUMITOMO CHEM CO LTD

A multifunctional screen protector

ActiveCN105058929BImprove anti-blue light effectLow yellownessSynthetic resin layered productsAntistatic agentAdhesive

The invention provides a multifunctional screen protection film which sequentially comprises a release film layer, an optimal adhesive layer, a base material layer and a multifunctional layer, wherein the optical adhesive layer is arranged on the release film layer, the base material layer is arranged on the optical adhesive layer, and the multifunctional layer is arranged on the base material layer and comprises an anti-blue-light agent, an antistatic agent and anti-newton's-ring coating resin. The multifunctional screen protection film has antistatic, anti-blue-light and anti-newton's-ring functions and has better anti-blue-light performance and the lower yellowing degree, so that the comfort degree of the screen protection film in use is increased. Besides, the multifunctional screen protection film is high in hardness, large in adhesive force, simple in structure, easy to produce and low in cost.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

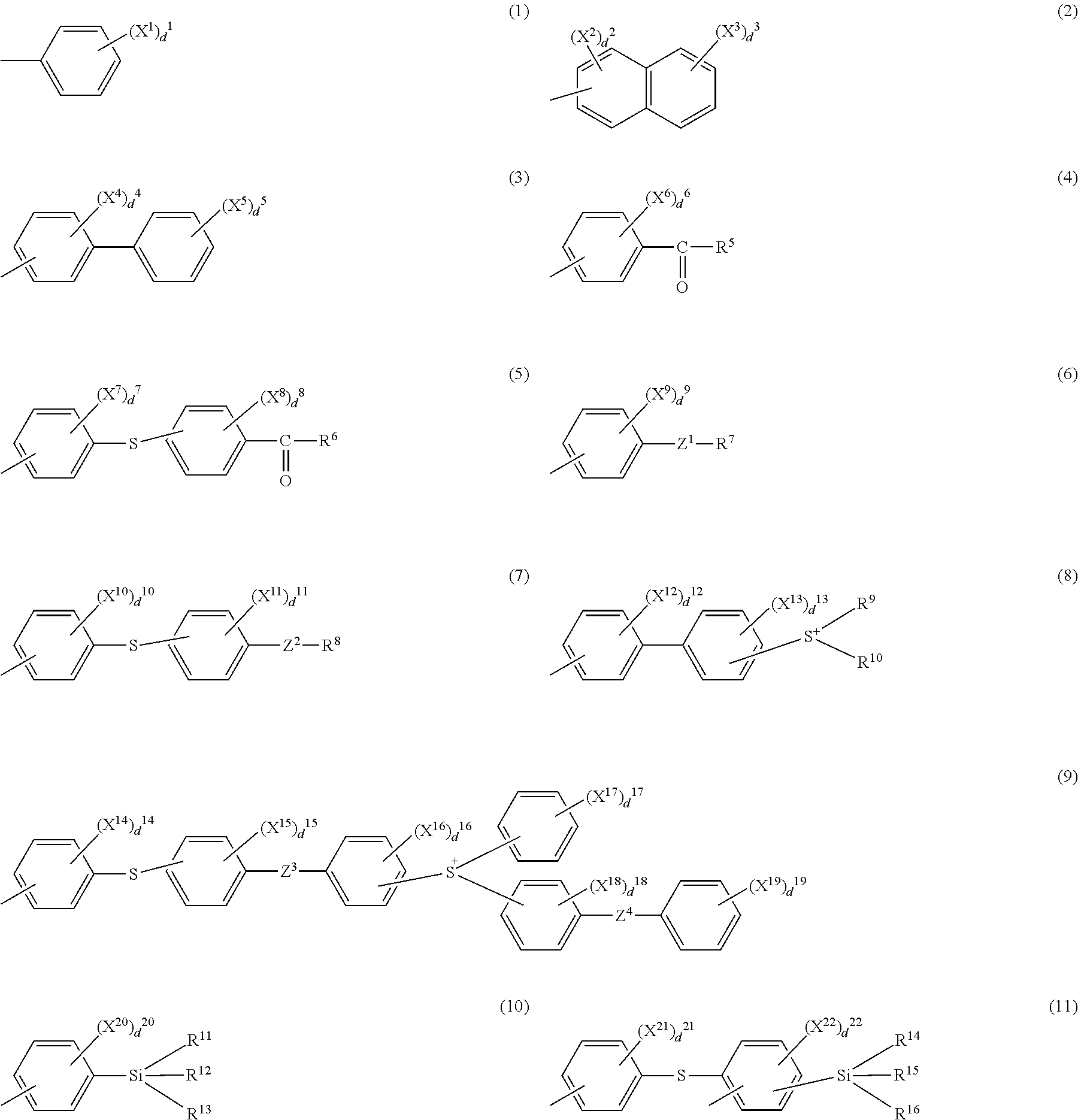

Resin composition for optical stereolithography

ActiveUS9416220B2Excellent in safety and handling propertyReduce yellowness3-dimensional image productionPhotosensitive materials for photomechanical apparatusPolymer scienceCationic polymerization

A resin composition for optical stereolithography including a cation-polymerizable organic compound (A), a radical polymerizable organic compound (B), a cationic polymerization initiator (C) and a radical polymerization initiator (D), wherein the cationic polymerization initiator (C) is an aromatic sulfonium compound (C-1) represented by the following general formula (C-1):wherein R1, R2, and R3 represent a monovalent organic group, Rf represents a fluoroalkyl group, m is the same number as the cationic charge of the “cation [S+(R1)(R2)(R3)]”, and n is an integer in a range of 0 to 6. The resin composition also includes an aromatic thiol compound (E) represented by the following general formula (E):R4SH)p (E)wherein, R4 represents a mono- or di-valent aromatic hydrocarbon which may optionally have a substituent, and p is an integer of 1 or 2.

Owner:CMET

Method for producing oxymethylene copolymer

ActiveUS20200354500A1Generation of formaldehyde is reducedOdor suppressionPolymer sciencePerchloric acid

A method for producing an oxymethylene copolymer which gives molded articles that are inhibited from emitting formaldehyde and can be reduced in yellowness is provided. In producing an oxymethylene copolymer, an effective polymerization initiator amount is regulated to a value within a given range, the amount being calculated from the amount of perchloric acid or a derivative thereof contained in the polymerization initiator and the amount of triethanolamine contained in all the monomers comprising trioxane and comonomers, which are starting materials for the copolymer.

Owner:MITSUBISHI GAS CHEM CO INC

Optical film and flexible display device

PendingCN114599739ALow yellownessImprove folding resistancePolarising elementsIdentification meansFlexible displayMaterials science

Provided is an optical film having low yellowness and excellent folding resistance. The optical film contains a polyimide-based resin, and has a yield strength in a tensile test of 81 MPa or more and a yellowness of less than 3.0.

Owner:SUMITOMO CHEM CO LTD

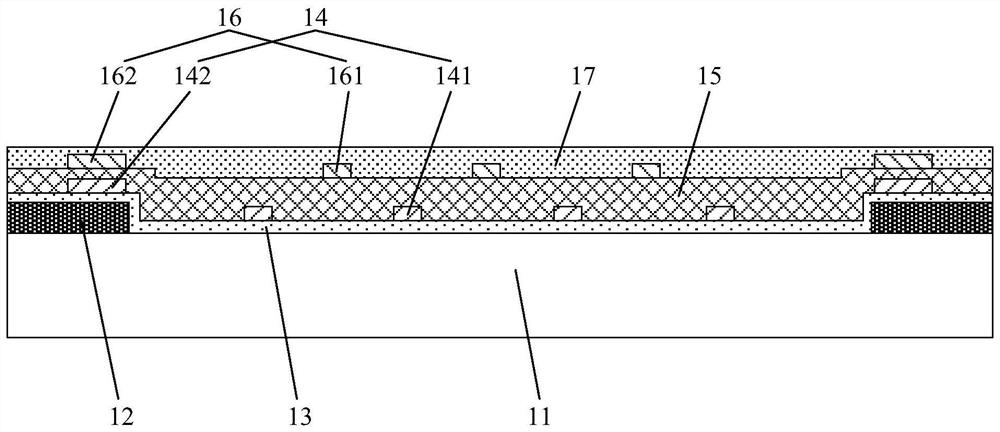

Touch substrate, preparation method thereof and display device

PendingCN112905049ASolve the yellowish colorAvoid shades of yellowInput/output processes for data processingDisplay deviceMaterials science

The embodiment of the invention provides a touch substrate, a preparation method thereof and a display device. The touch substrate comprises a visible region, and the touch substrate comprises a cover plate substrate; the touch structure layer is located on one side of the cover plate substrate; and the chromaticity function layer is at least located in the visible region and is configured to reduce the yellow chromaticity of the visible region of the touch substrate. The chromaticity function layer can reduce the yellow chromaticity of the visible region of the touch substrate, and the situation that the chromaticity of the visible region of the touch substrate is slightly yellow is avoided.

Owner:BOE TECH GRP CO LTD +1

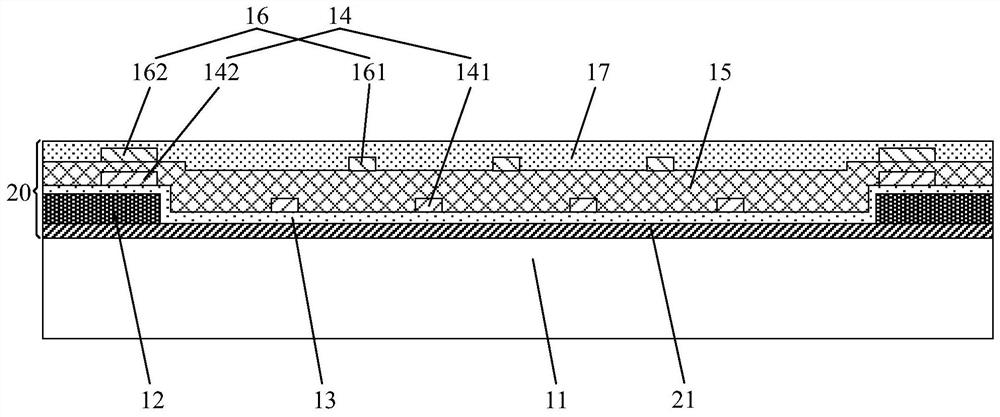

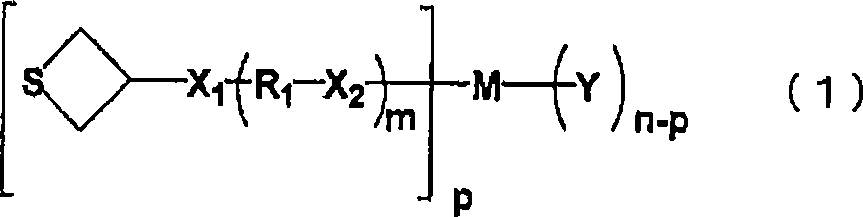

Polymerizable composition, resin using the same, optical component and lens

Disclosed is a polymerizable composition containing a compound represented by the general formula (1) below and a blueing agent. (In the general formula (1) below, M represents a metal atom; X1 and X2 independently represent a sulfur atom or an oxygen atom; R1 represents a divalent organic group; m represents 0 or an integer of not less than 1; p represents an integer of not less than 1 but not more than n; n represents the valence of the metal atom M; Y's independently represent an inorganic or organic residue, and when n-p is not less than 2, Y's may combine together to form a ring containing the metal atom M.

Owner:MITSUI CHEM INC

Scratch-resistant protective film for AMOLED display screen

The invention discloses a scratch-resistant protective film for an AMOLED display screen. The scratch-resistant protective film comprises a release film layer, a protective film adhesive layer arranged on the release film layer, a TAC base film layer arranged on the protective film adhesive layer, and a multifunctional layer arranged on the TAC base film layer, wherein the multifunctional layer comprises an anti-ultraviolet blue UV layer, an antistatic layer and a nano absorption layer. The scratch-resistant protective film has anti-static and anti-blue light functions at the same time, has relatively good anti-blue light property and also has relatively low yellowness, the use comfort of the screen protective film is improved, and the scratch-resistant protective film is capable of effectively eliminating reflected light and strong glare while having high permeability, and is relatively good in scratch resistance.

Owner:HEFEI HUIKE PRECISION DIE CO LTD

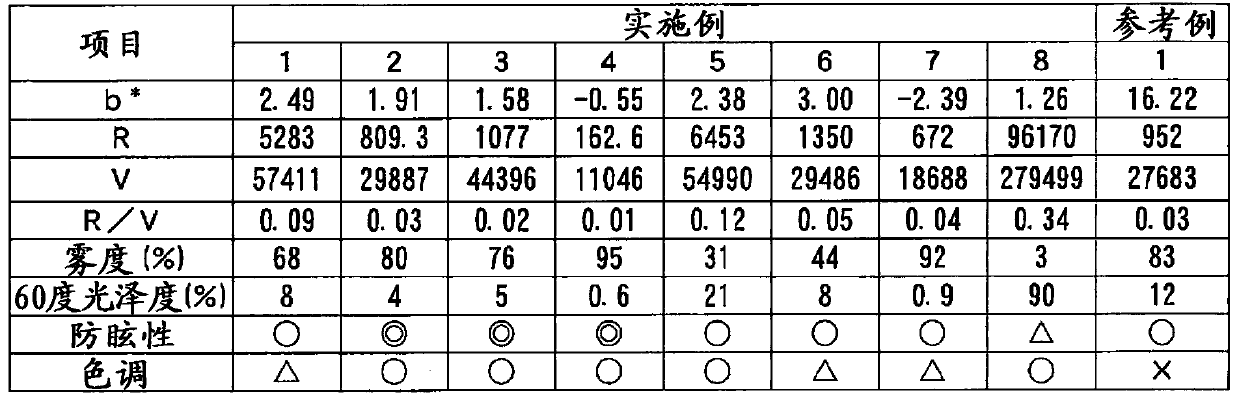

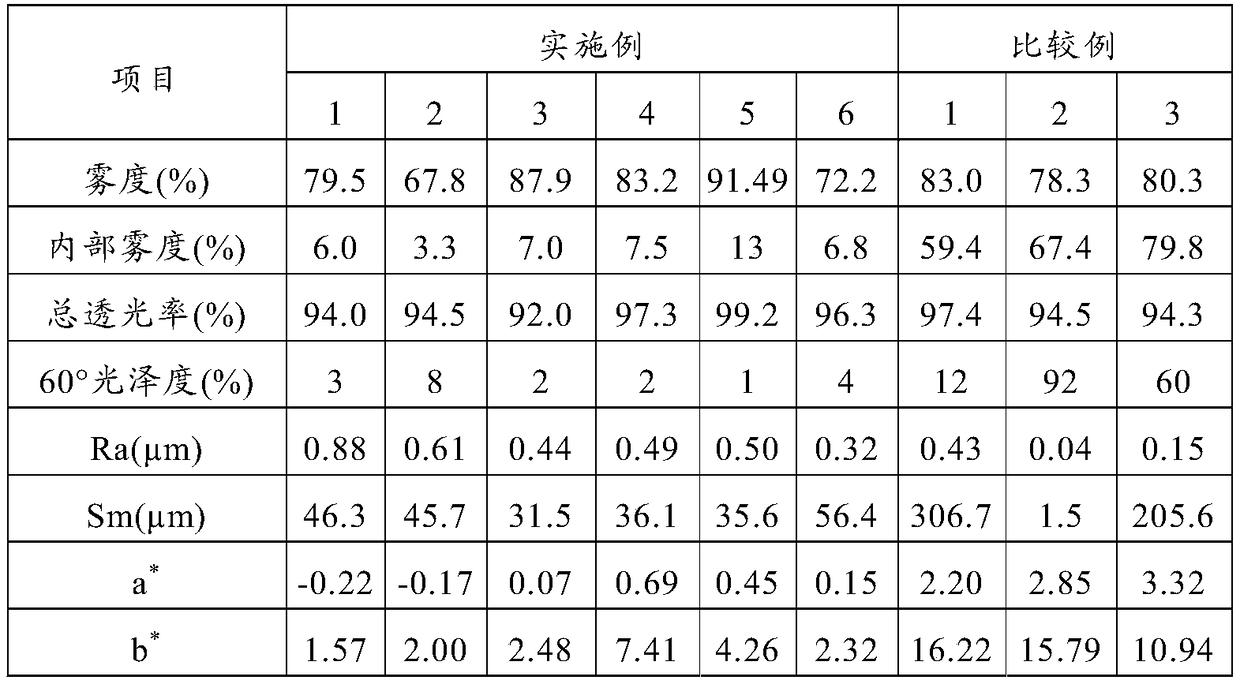

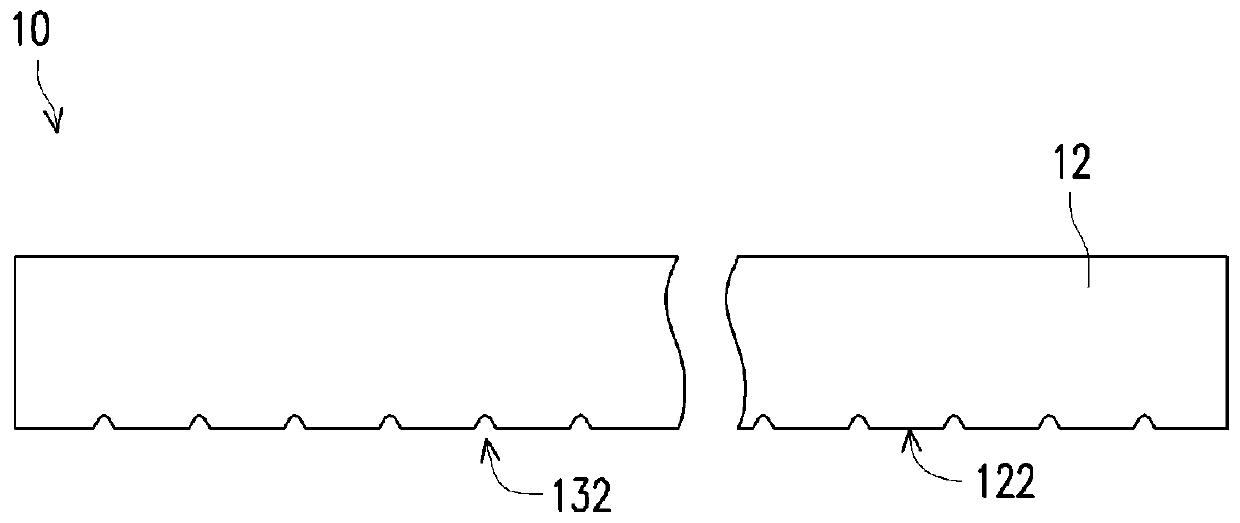

Light-diffusing film and production method therefor, and display device

PendingCN109313288AHigh transparencyLow yellownessDiffusing elementsSynthetic resin layered productsDisplay deviceTransmittance

The present invention addresses the problem of preparing a light-diffusing film that has a haze of at least 50%, an inner haze of at most 15%, and a total light transmittance of at least 90%. This light-diffusing film may be configured such that the light transmitted therethrough has a chromaticity b* of 10 or less and a chromaticity a* of 2 or less. The light-diffusing film includes a transparentfilm and a light-diffusing layer formed on at least one side of the transparent film, and the light-diffusing layer may have a 60 DEG-gloss value of 10% or less. The surface of the light-diffusing layer may have an arithmetic average surface roughness Ra of 0.3 mum or more. The average interval Sm between the irregularities on the surface of the light-diffusing layer may be 100 mum or less. The light-diffusing layer can be a cured material of a curable compound that contains at least one type of a polymer component and at least one type of a cured resin precursor component. This light-diffusing film exhibits high degrees of light diffuseness and luminance.

Owner:DAICEL CHEM IND LTD

Polymethacrylate composition, optical device made therefrom, and display apparatus

The invention provides a polymethacrylate composition, an optical device made therefrom, and a display apparatus. The polymethacrylate composition includes 50 to 85 parts by weight of methacrylate series polymer, and 15 to 50 parts by weight of styrene series-maleic anhydride series copolymer. The methacrylate series polymer includes methacrylate series monomer unit and acrylate series monomer unit and has a weight average molecular weight (Mw) in a range between 20,000 and 200,000. Based on the total weight of the styrene series-maleic anhydride series copolymer, the styrene series-maleic anhydride series copolymer includes 76.5wt%-90wt% of styrene series monomer unit, and 10wt%-23.5wt% of maleic anhydride series monomer unit. A range of molecular weight distribution index (PDI) of the styrene series-maleic anhydride series copolymer is from 1.5 to 2.05.

Owner:CHI MEI CORP

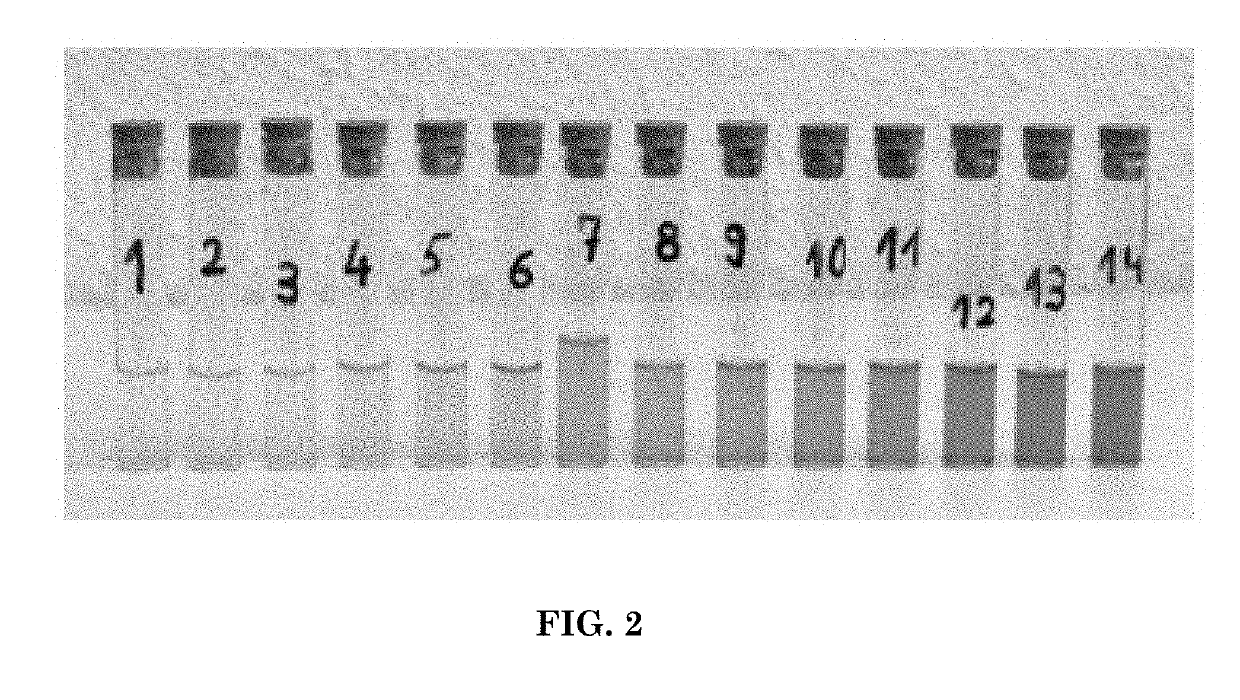

Process for making expandable polyvinyl chloride paste containing trimellitate plasticizers

InactiveUS20190177502A1Low yellownessUniform densityDomestic upholsteryLayered productsEmulsionPolymer chemistry

The present disclosure relates to the processing of a flexible polyvinyl chloride foam having predetermined characteristics formed from a polyvinyl chloride emulsion including polyvinyl chloride resin and a plasticizer by controlling one or more of the following: a concentration of stabilizer in the final foam, a heating rate during processing, a maximum temperature during fusion, and / or a total residence time during heating. Predetermined characteristics of interest for a flexible PVC foam may include, for example, low yellowness, uniform density, high compression modulus and / or a uniform cell morphology.

Owner:MANDUKA LLC

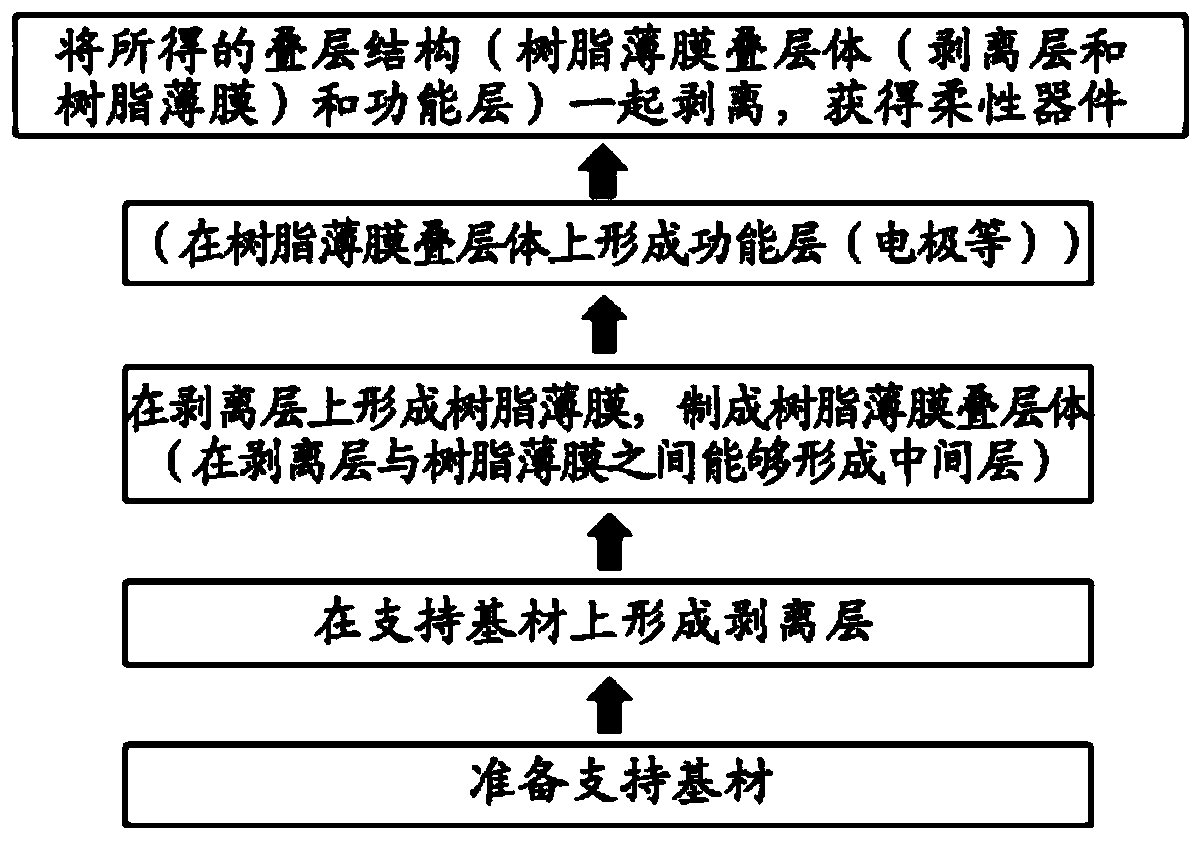

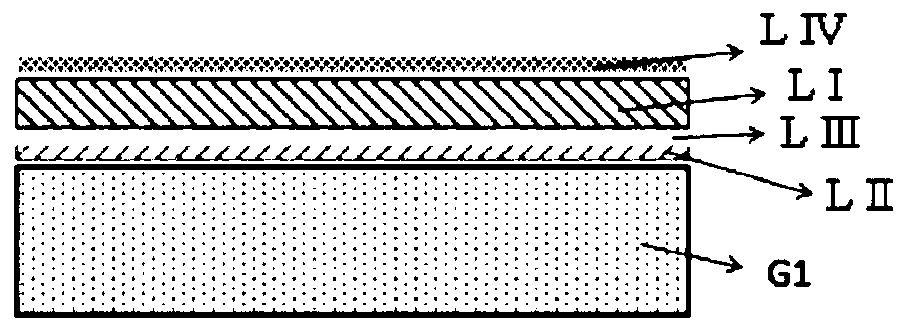

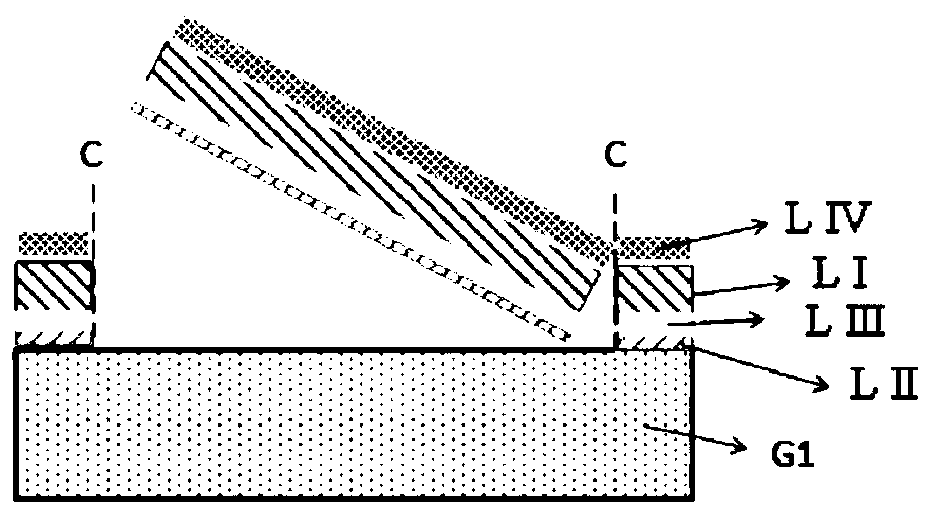

Method for producing substrate for flexible device

ActiveCN111344130AEasy to manufactureEasy to peelSynthetic resin layered productsCoatingsPolymer scienceOrganic solvent

The purpose of the present invention is to provide a method for forming a resin thin film laminate that makes it possible to preserve the exceptional performance attributes of exceptional heat resistance, low retardation, exceptional flexibility, and exceptional transparency, said resin thin film laminate being applied to a plastic thin film having exceptional performance as a base film of a flexible device substrate such as a flexible display substrate that can be easily peeled from a glass carrier. A method for producing a resin thin film laminate, said resin thin film laminate being characterized in that after a peeling layer is formed on a support substrate using a peeling-layer-forming composition containing a heat resistant polymer and an organic solvent, a resin thin film is formedon the peeling layer using a resin thin film-forming composition containing a heat resistant polymer and an organic solvent, and the peeling layer and the resin thin film are subsequently peeled fromthe support substrate as a single entity, said method being further characterized in that silicon dioxide particles having an average particle diameter of 100 nm or less as calculated from the specific surface area measured by nitrogen adsorption are incorporated in substantially only the resin thin film-forming composition.

Owner:NISSAN CHEM IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com