Optical film

An optical film, polyamide-imide technology, applied in the field of optical film, can solve the problems of easy cracking and difficult front panel material utilization, and achieve the effect of high elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

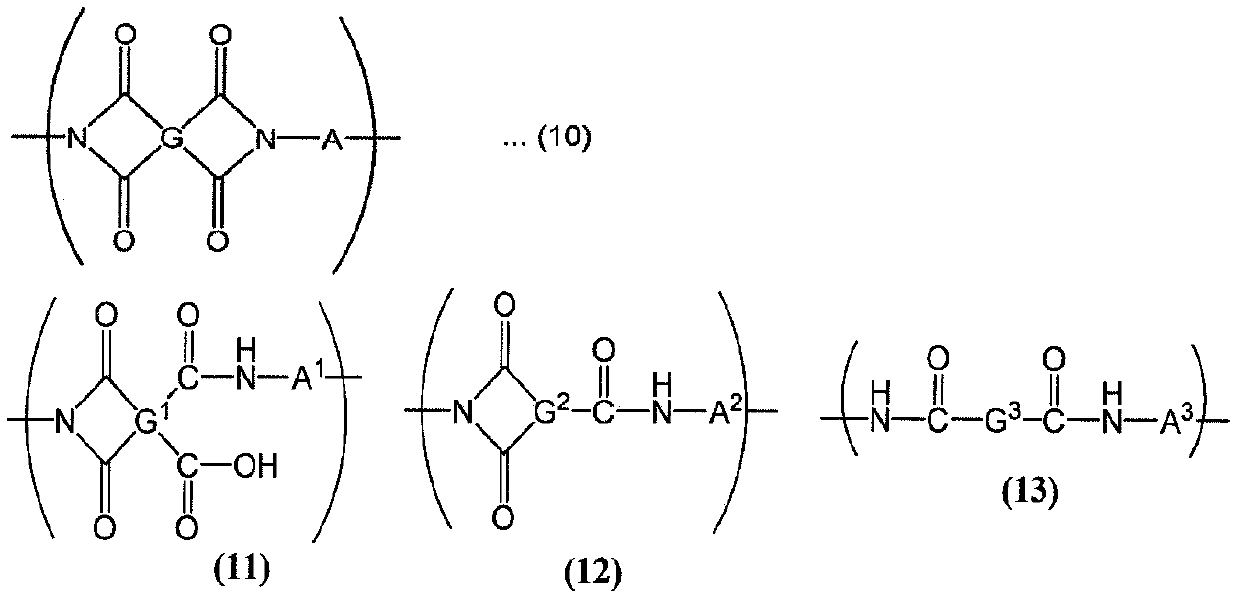

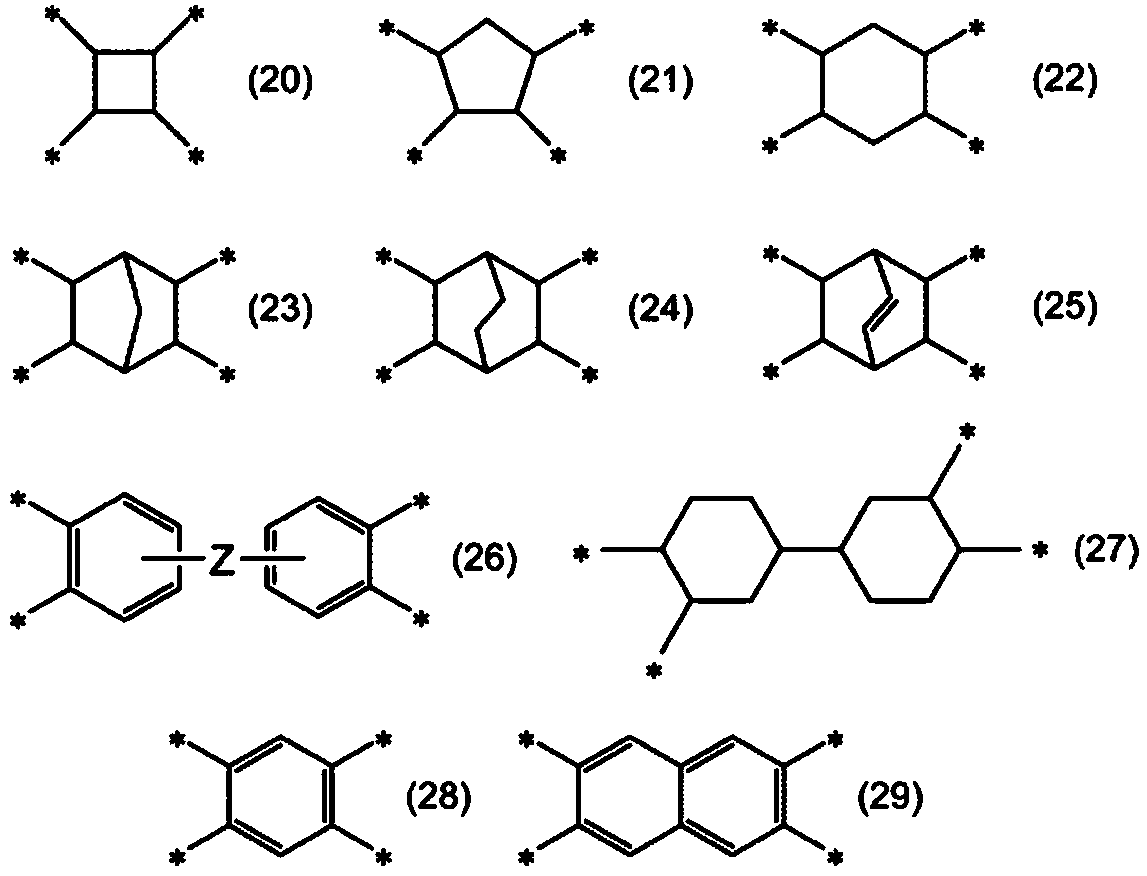

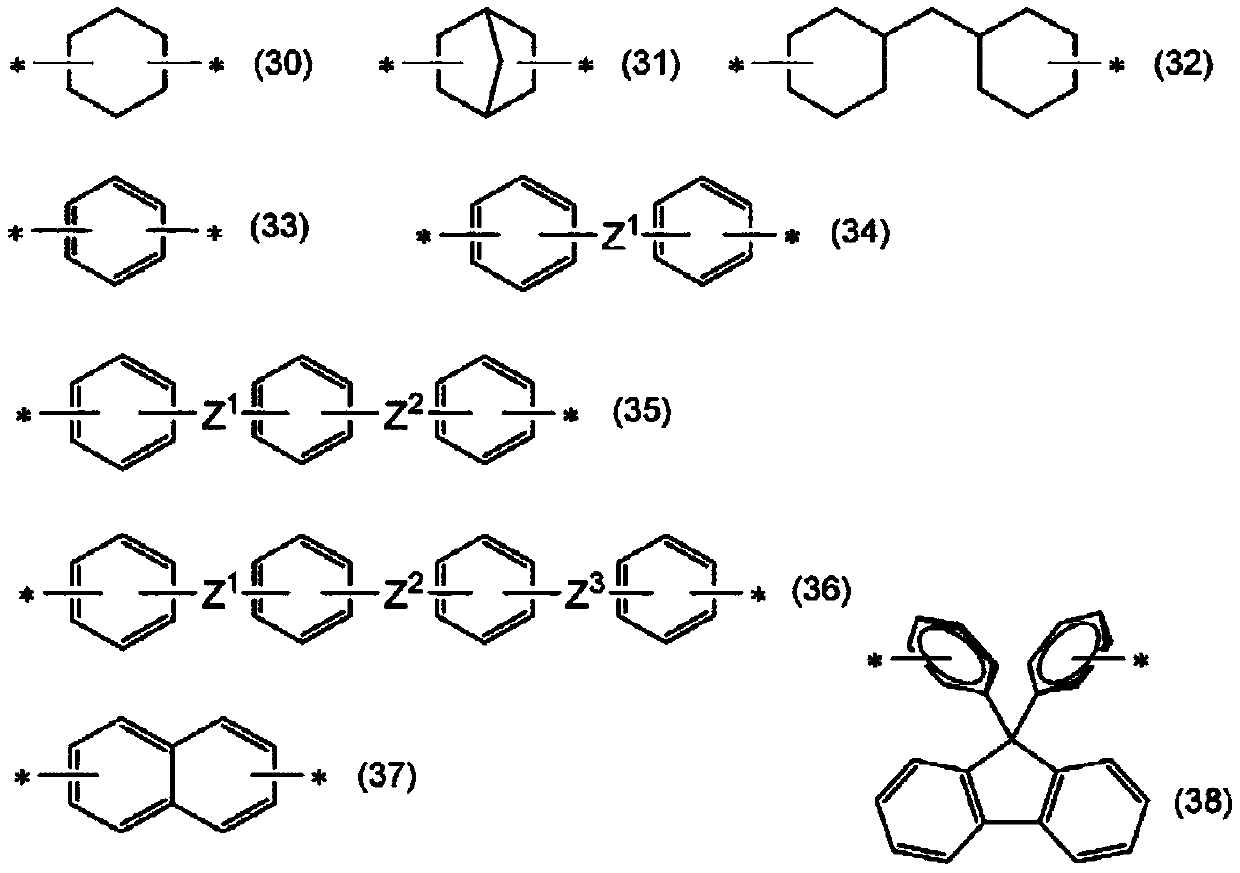

Method used

Image

Examples

preparation example Construction

[0127] The solvent usable in the preparation of the varnish is not particularly limited as long as it can dissolve the aforementioned resin. Examples of the solvent include amide-based solvents such as N,N-dimethylacetamide and N,N-dimethylformamide; lactone-based solvents such as γ-butyrolactone and γ-valerolactone; Sulfur-containing solvents such as dimethyl sulfone, dimethyl sulfoxide, and sulfolane; carbonate-based solvents such as ethylene carbonate and 1,2-propylene carbonate; and combinations thereof. Among these, amide-based solvents or lactone-based solvents are preferable. These solvents can be used individually or in combination of 2 or more types. In addition, water, alcohol-based solvents, ketone-based solvents, acyclic ester-based solvents, ether-based solvents, and the like may be contained in the varnish. The solid content concentration of the varnish is preferably 1 to 25% by mass, more preferably 5 to 15% by mass.

[0128] In the coating step, the varnish ...

Embodiment 1

[0230] (Preparation of silica sol)

[0231] In a 1000 mL flask, 517.2 g of methanol-dispersed silica sol (“MA-ST-M” manufactured by Nissan Chemical Industries, Ltd., primary particle size: 23 nm, solid content of silica particles: 40.6%) and γ-butylene Lactone (GBL) 490.9g, methanol was evaporated at 400hPa for 1 hour at 400hPa, and methanol was evaporated at 250hPa for 1 hour in a hot water bath at 45°C using a vacuum evaporator. Furthermore, the temperature was raised to 70° C. at 250 hPa, and heating was performed for 30 minutes to obtain γ-butyrolactone-dispersed silica sol 1 (GBL-dispersed silica sol 1). The solid content concentration of the obtained GBL-dispersed silica sol 1 was 29.8%.

[0232] (Preparation of polyamideimide)

[0233]Under a nitrogen atmosphere, 45 g (140.52 mmol) of 2,2'-bis(trifluoromethyl)-4,4'-diaminobiphenyl (TFMB) and N , N-dimethylacetamide (DMAc) 768.55g, TFMB was dissolved in DMAc while stirring at room temperature. Next, 18.92 g (42.58 mm...

Embodiment 2

[0239] Instead of methanol-dispersed silica sol "MA-ST-M", methanol-dispersed silica sol (manufactured by Nissan Chemical Industries, Ltd., "MA-ST-G-ML1", primary particle size: 27nm) was used, and in addition, the same In the same manner as in Example 1, an optical film was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com