Polymethacrylate composition, optical device made therefrom, and display apparatus

A polymethacrylate and methacrylate technology, which is applied in the field of optical components and display equipment, can solve problems such as affecting the optical properties of polymethacrylate, and achieve excellent display effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

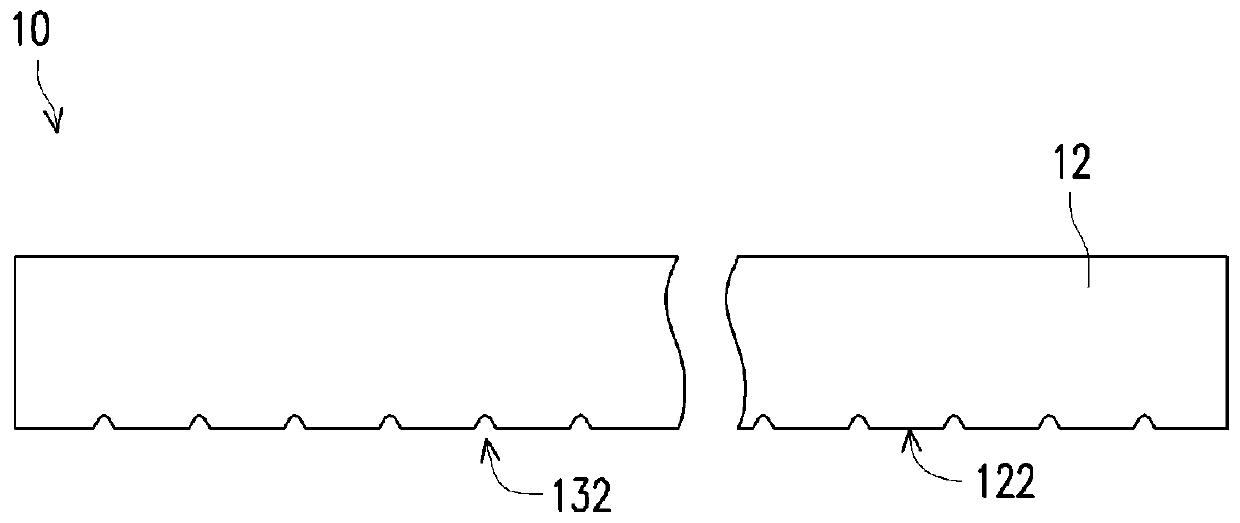

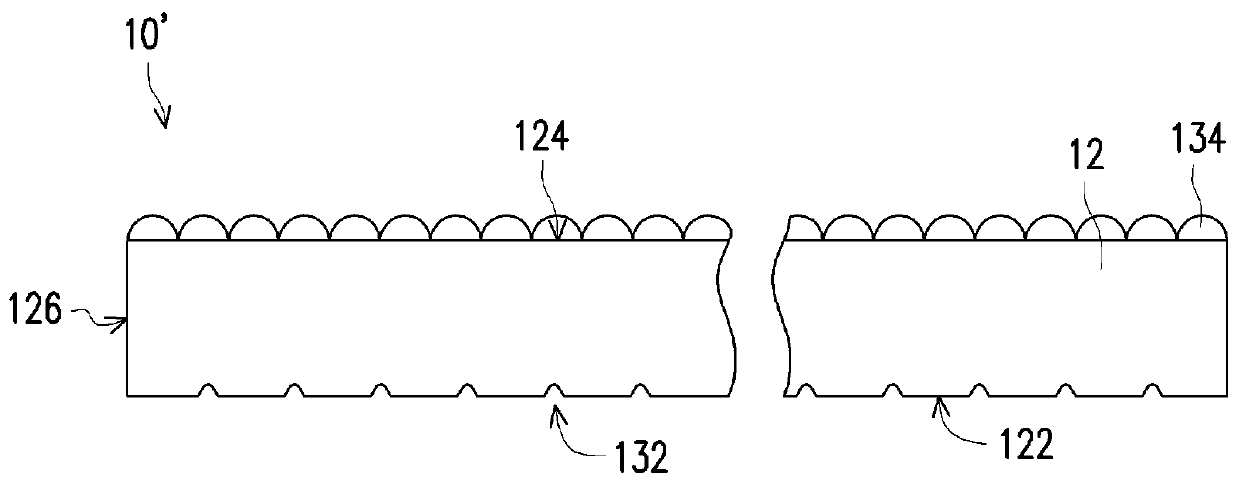

Image

Examples

preparation example Construction

[0070] 1.1. Preparation of PMMA

[0071] First, mix 95 parts by weight of methyl methacrylate, 5 parts by weight of methyl acrylate, 0.4 parts by weight of n-dodecyl mercaptan, 0.08 parts by weight of 2,2'-azobisisobutyronitrile, and 66 parts by weight of toluene Afterwards, it is continuously sent to a reaction tank for continuous solution polymerization. The above-mentioned reaction tank is an interlayer with heat medium oil circulation, and the reaction temperature is maintained at 100° C. and the pressure is 600 torr. Thoroughly stir the components in the reaction tank to make them evenly mixed, and heat the obtained polymer solution to 265°C, then use a continuous devolatilization device to devolatilize the above polymer solution under reduced pressure, and then pass it through the extrusion equipment to produce strips. After cooling and pelletizing, polymethyl methacrylate plastic particles are obtained. The polymethyl methacrylate plastic particles contain 97 wt% of ...

Embodiment 1 to 9

[0090] Examples 1 to 9 are mixed according to the proportions of the ingredients listed in Table 2, and then mixed and extruded with an extruder at 240°C to granulate, and then the polymethacrylate compositions are obtained respectively. The haze (HAZE), The test results of yellowness (YI), light transmittance (T%) and glass transition temperature (Tg) are also described in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com