Manufacturing method of polyamide

A manufacturing method, polyamide technology, applied in the field of polyamide, can solve problems such as undisclosed temperature, achieve the effect of increasing commodity value, easy adjustment, and high industrial utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

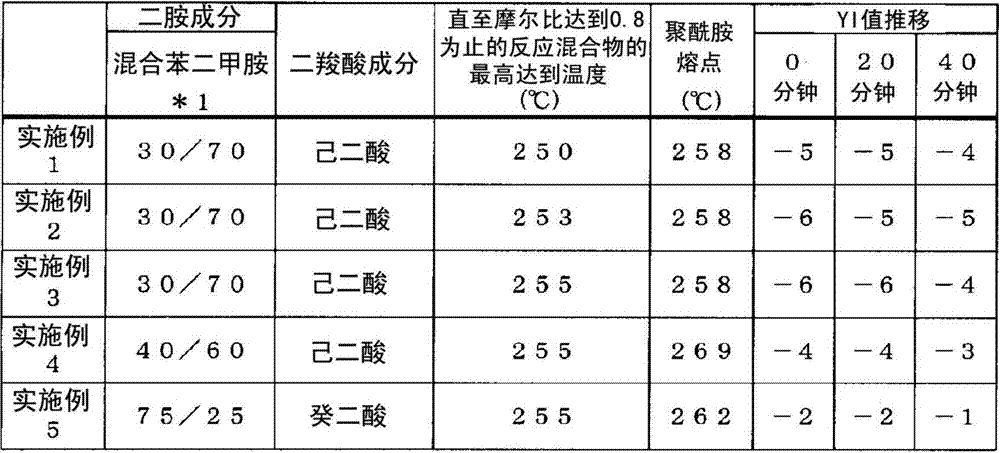

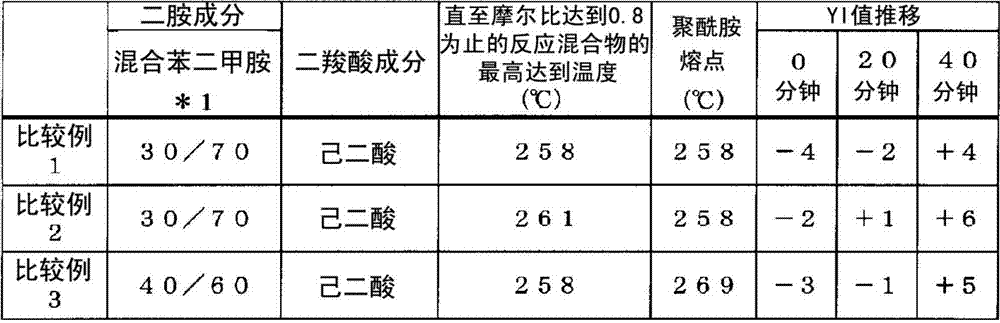

Examples

Embodiment 1

[0057]Into a jacketed 50-liter stainless steel reaction tank equipped with a partial condenser, a total condenser, a stirrer, a nitrogen gas inlet pipe, and a diamine dropping port through which temperature-adjusted oil flows, accurately weighed 15.000 kg of adipic acid (purity: 99.85wt%) was fed as powder and fully replaced with nitrogen. The oil at 300°C was poured into the jacket to start heating up, and the adipic acid was melted while stirring to form a uniform flow state. During this period, supply of nitrogen gas into the reaction tank was started, and the pressure in the reaction tank was increased to 0.3 MPaG. When heated to 190° C., while stirring the molten adipic acid, 13.909 kg of mixed xylylenediamine (purity: 99.95 wt%) containing 70 mol% m-xylylenediamine and 30 mol% p-xylylenediamine were consumed. Add dropwise over 2 hours. During the dropwise addition of the diamine component, until the molar ratio (diamine component / dicarboxylic acid component) in the rea...

Embodiment 2

[0059] During the dropwise addition of the diamine component until the molar ratio (diamine component / dicarboxylic acid component) in the reaction mixture reaches 0.8, in addition to raising the temperature of the reaction mixture with 253°C as the upper limit and maintaining it in a molten state, It carried out similarly to Example 1. The obtained polyamide had a melting point of 258° C. and a number average molecular weight of 16,000. As shown in Table 1, the yellowness (YI) of the obtained polyamide pellets was -6 at the beginning of taking out, -5 after 20 minutes, and -5 after 40 minutes. Almost no increase in YI over time was confirmed, and a color tone was obtained. Good polyamide.

Embodiment 3

[0061] During the dropwise addition of the diamine component until the molar ratio (diamine component / dicarboxylic acid component) in the reaction mixture reaches 0.8, in addition to raising the temperature of the reaction mixture with 255°C as the upper limit and maintaining it in a molten state, It carried out similarly to Example 1. The obtained polyamide had a melting point of 258° C. and a number average molecular weight of 16,000. As shown in Table 1, the yellowness (YI) of the obtained polyamide pellets was -6 at the beginning of taking out, -6 after 20 minutes, and -4 after 40 minutes. Almost no increase in YI over time was confirmed, and the color tone was obtained. Good polyamide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com