Touch substrate, preparation method thereof and display device

A technology of touch control and substrate, which is applied in the directions of instruments, calculations, electrical digital data processing, etc., to achieve the effect of avoiding yellowish chromaticity and solving yellowish chromaticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

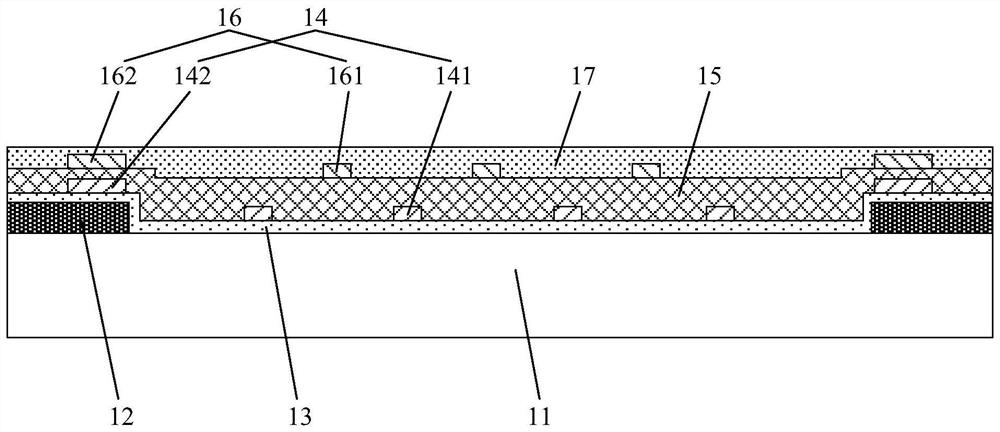

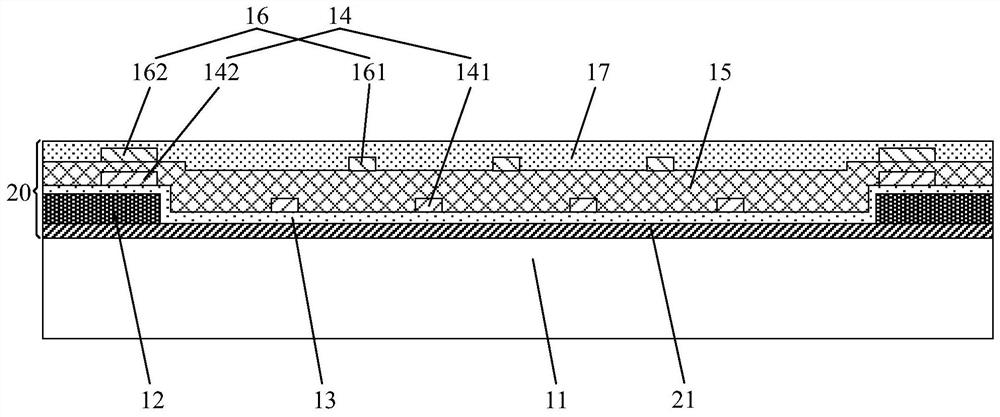

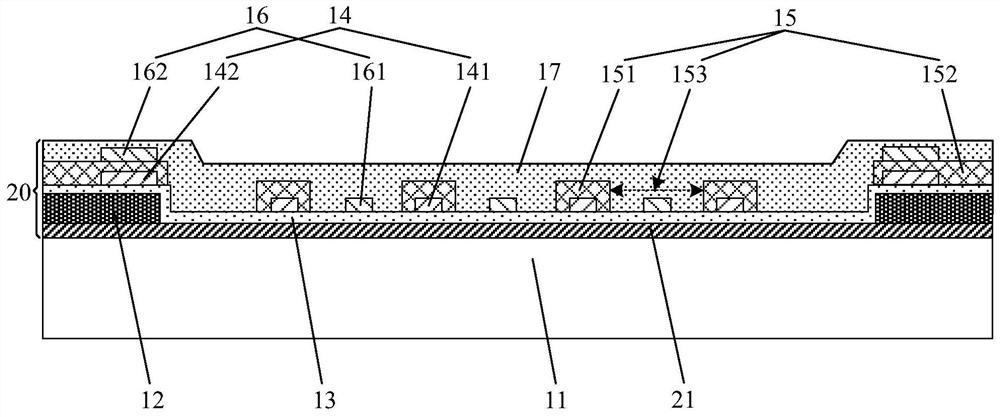

[0052] figure 1 The preparation process of the shown touch substrate may include:

[0053] Toughened glass is selected as the cover substrate, and ultrasonic cleaning is performed on the cover substrate 11 . A light-shielding layer 12 located in the frame area is formed on one side of the cover substrate 11 , and yellow light coating and developing processes can be used in the process of making the light-shielding layer. A protective layer 13 is formed on the side of the light-shielding layer 12 away from the cover substrate 11. The material of the protective layer 13 is an organic substance, such as a photolithographic insulating protective glue (also called a photolithographic OC glue). In the process of forming the protective layer 13, Yellow light coating and development processes can be used, and high temperature baking at 200°C for about 30 minutes is required for curing. The first metal layer 14 is formed on the side of the protective layer 13 away from the cover subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com