Preparation process of a controllable color silver nanowire conductive film

A technology of silver nanowires and conductive films, which is applied in cable/conductor manufacturing, conductive layers on insulating carriers, circuits, etc., can solve the problems of undiscovered suitable modification materials or dyes, and achieve excellent light fastness and humidity Dealing with fastness, increasing application scenarios and scope, and controlling the effect of dyeing depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation process of the color-controllable silver nanowire conductive film of this embodiment is to first coat the silver nanowire conductive ink containing epoxy ethylene type surfactant on the PET film as a transparent substrate and dry it (temperature 120 ℃, Time 30min), and then apply B-2GLN reactive blue solution with a concentration of 0.1mg / mL on the surface and dry (temperature 120°C, time 30min) to obtain.

[0032] Wherein, the composition of each raw material of silver nanowire conductive ink by mass fraction is:

[0033]

Embodiment 2~7

[0035] Examples 2 to 6 were prepared by the same method as in Example 1, except that the concentration of the azo metal complex dye solution was changed, or replaced with chloroauric acid solution. As a comparison, no alkylphenol polyoxyethylene ether was added to the silver nanowire conductive ink used in Example 7, and no azo metal complex dye solution or chloroauric acid solution was coated on the surface of the conductive layer. See Table 1 for details.

[0036] Table 1

[0037] Example surface modifier Concentration (mg / mL) 1 B-2GLN reactive blue 0.1 2 B-2GLN reactive blue 0.5 3 B-2GLN reactive blue 1 4 Chlorauric acid 0.1 5 Chlorauric acid 0.5 6 Chlorauric acid 1 7 none none

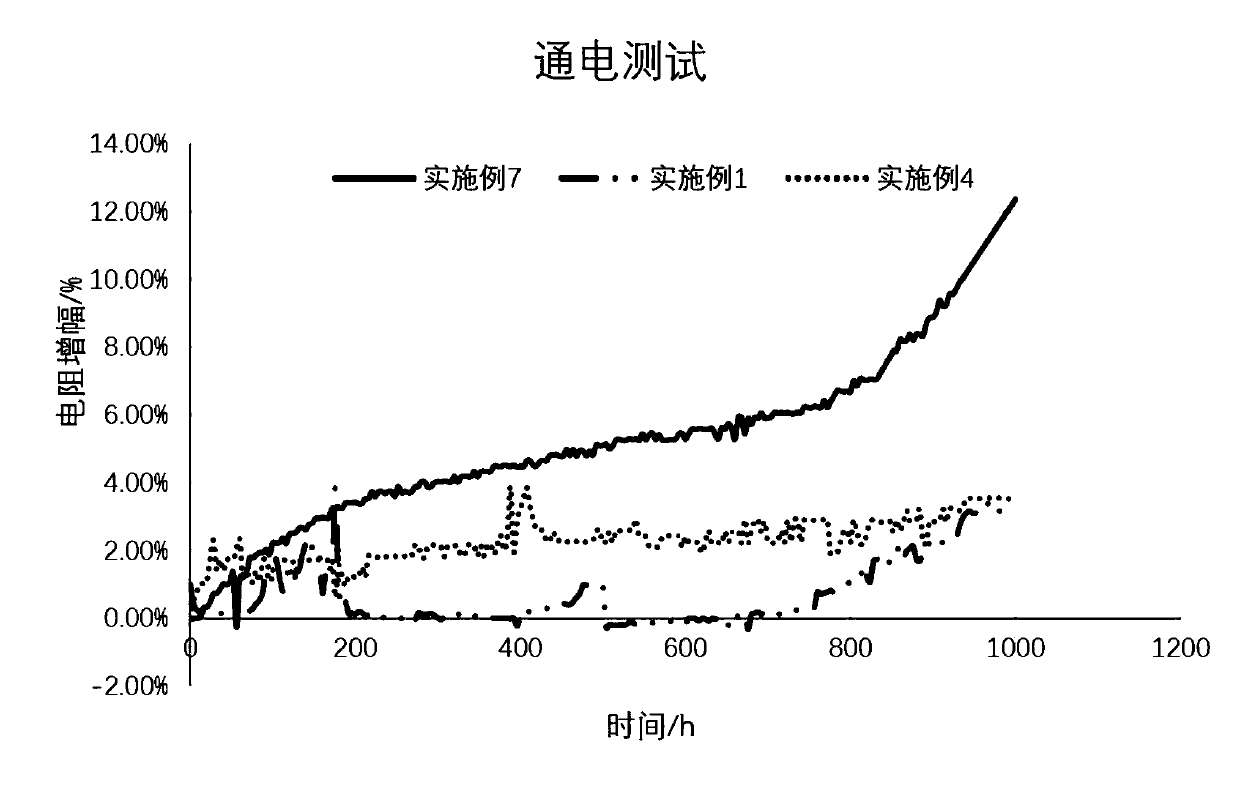

[0038] Performance Testing:

[0039] The transmittance and haze of the silver nanowire conductive film obtained in each embodiment were measured with a photoelectric haze tester of the Shenguang brand WGW. Use a four-probe squar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com