Polyimide precursor, resin composition comprising same, polyimide resin film, resin film, and method for producing same

A technology of polyimide precursor and resin composition, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., and can solve the problems that are difficult to use in fields requiring transparency and low light transmittance in the visible light region and other problems, to achieve the effect of excellent laser peeling, low yellowness, and less warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

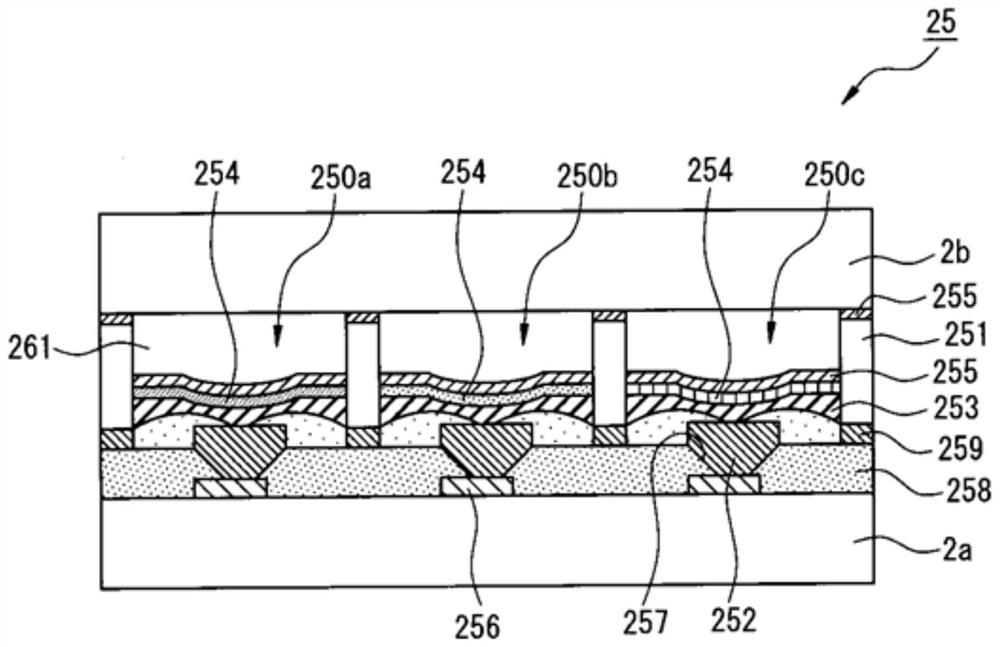

[0314] figure 1 It is a schematic diagram showing the structure above the polyimide substrate of a top-emission type flexible organic EL display as an example of the display of this embodiment.

[0315] against figure 1 The organic EL structure part 25 will be described. In the organic EL structure part 25, for example, an organic EL element 250a emitting red light, an organic EL element 250b emitting green light, and an organic EL element 250c emitting blue light are used as a unit, and are arranged in a matrix, and the partition walls (bank) 251 to define the light emitting area of each organic EL element. Each organic EL element is composed of a lower electrode (anode) 252 , a hole transport layer 253 , a light emitting layer 254 , and an upper electrode (cathode) 255 . In addition, a plurality of TFTs 256 ( It is selected from low-temperature polysilicon (LTPS), metal oxide semiconductor (IGZO, etc.), interlayer insulating film 258 having contact hole 257 , and low...

Embodiment

[0328] Hereinafter, the present invention will be described in more detail based on examples, but these are described for explanation, and the scope of the present invention is not limited to the following examples.

[0329] Various evaluations in Examples and Comparative Examples were performed as follows.

[0330]

[0331] Weight average molecular weight (Mw) and number average molecular weight (Mn) were measured by gel permeation chromatography (GPC) under the following conditions.

[0332] As a solvent, N,N-dimethylformamide (manufactured by Fujifilm Wako Pure Chemical Industries, Ltd., for high performance liquid chromatography) was used, and 24.8 mmol / L of lithium bromide monohydrate (manufactured by Fujifilm Wako Pure Chemical Industries, Ltd.) was added immediately before measurement. , purity of 99.5%) and 63.2 mmol / L phosphoric acid (manufactured by Fujifilm Wako Pure Chemical Industries, Ltd., for high performance liquid chromatography) and dissolved therein). A ...

Synthetic example 1(1-1

[0380] 90.00 g of N-methyl-2-pyrrolidone (NMP) was dropped into a 500 ml separable flask replaced with nitrogen, and 11.30 g (49.5 mmol) of 4-aminophenyl-4-aminobenzoate (APAB), 4,4-Azodiphenylamine (AzBz) 1.06 mg (5.0 μmоl) was stirred to dissolve APAB and AzBz. Thereafter, 14.7 g (50 mmol) of biphenyl-3,3', 4,4'-tetracarboxylic dianhydride (BPDA) and 13.25 g of N-methyl-2-pyrrolidone (NMP) were added to form the polyamic acid The concentration was adjusted so as to be 20% by mass, and the polymerization reaction was performed under a nitrogen stream at 80° C. and stirring for 3 hours. Then, it cooled to room temperature and obtained the NMP solution (it is also hereafter called the varnish containing a polyimide precursor) of a polyamic acid. The weight average molecular weight (Mw) of the obtained polyamic acid was about 100,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com