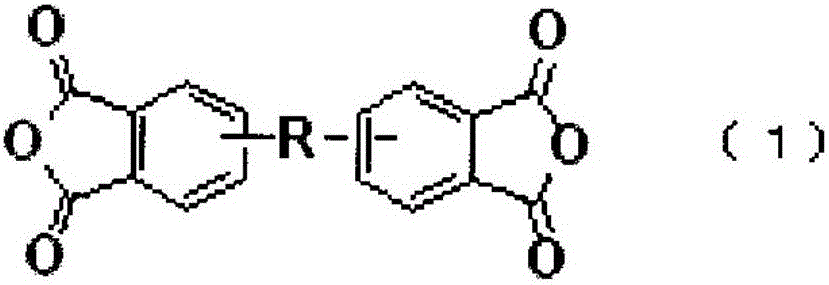

Resin precursor, resin composition containing same, polyimide resin membrane, resin film, and method for producing same

A technology of polyimide resin and resin composition, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, flat products, etc., and can solve the problems of low light transmittance, difficult to be used in fields requiring transparency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0282] Hereinafter, the present invention will be described in more detail based on examples, but these are described for illustration only, and the scope of the present invention is not limited to the following examples.

[0283] Various evaluations in Examples and Comparative Examples were performed as follows.

[0284] (Determination of weight average molecular weight and number average molecular weight)

[0285] The weight average molecular weight (Mw) and the number average molecular weight (Mn) were measured by gel permeation chromatography (GPC) under the following conditions. As a solvent, N,N-dimethylformamide (manufactured by Wako Pure Chemical Industries, Ltd., for high performance liquid chromatography) was used, and lithium bromide monohydrate (manufactured by Wako Pure Chemical Industries, Ltd.) to which 24.8 mmol / L was added before measurement was used. Co., Ltd., purity 99.5%) and 63.2 mmol / L phosphoric acid (Wako Pure Chemical Industries, Ltd., for high perfo...

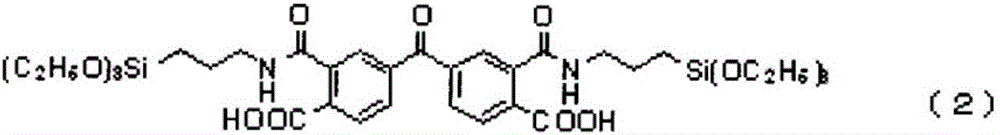

Synthetic example 1

[0296]A 50ml detachable flask was replaced with nitrogen, and 19.5 g of N-methyl-2-pyrrolidone (NMP) was put into the detachable flask, and then BTDA (benzophenone tetracarboxylate) as raw material compound 1 was put into the detachable flask. Acid dianhydride) 2.42g (7.5mmol) and 3-aminopropyltriethoxysilane (trade name: LS-3150, manufactured by Shin-Etsu Chemical Co., Ltd.) as raw material compound 2 3.321g (15mmol), react at room temperature 5 hours to obtain an NMP solution of alkoxysilane compound 1.

[0297] This alkoxysilane compound 1 was prepared as a 0.001% by mass NMP solution, filled in a quartz cuvette with a measurement thickness of 1 cm, and the absorbance when measured with UV-1600 (manufactured by Shimadzu Corporation) was 0.13.

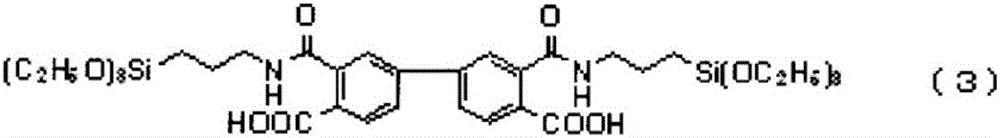

Synthetic example 2~5

[0299] In the above-mentioned Synthesis Example 1, the usage amount of N-methyl-2-pyrrolidone (NMP) and the types and usage amounts of the raw material compounds 1 and 2 were set to the usage amounts described in Table 1, respectively. 1. NMP solutions of alkoxysilane compounds 2-5 were obtained in the same manner.

[0300] These alkoxysilane compounds were each made into a 0.001% by mass NMP solution, and the absorbance measured in the same manner as in Synthesis Example 1 above is shown in Table 1 together.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com