A device and process for preparing high molecular weight polyester by ring-opening polymerization of cyclic ester

A high-molecular-weight, ring-opening polymerization technology is applied in the field of devices for preparing high-molecular-weight polyesters by ring-opening polymerization of cyclic esters. , Low yellowness value, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

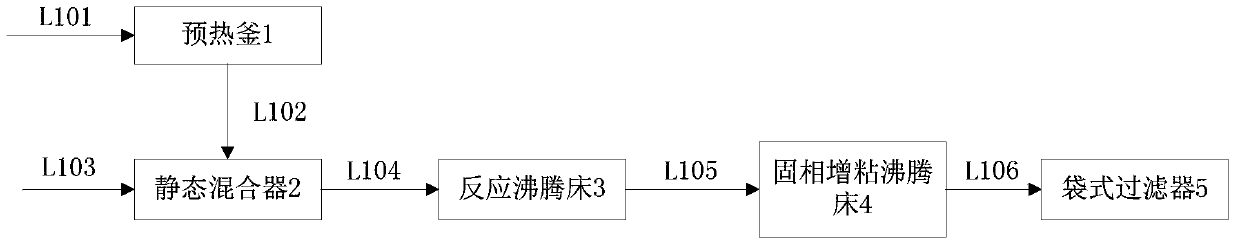

Embodiment 1

[0037] Heat and melt 100 weight of glycolide at 90°C, mix with 0.3 weight of stannous octoate and 0.35 weight of triphenyl phosphite through a static mixer, and then spray it into a 245°C high-purity nitrogen chamber with a flow rate of 0.4L / min. After reacting in the ebullating bed for 15 minutes, the powdered polyglycolic acid resin was blown into the ebullating bed at 230° C., and the high-purity nitrogen solid-phase viscosity-increasing ebullating bed was discharged for 4 hours after the solid-phase viscosity-increasing reaction, and collected. And analyze the polyglycolic acid resin powder. The weight average molecular weight Mw of the obtained polyglycolic acid resin was measured to be 218000, the molecular weight distribution was 1.8, and the yellowness index YI was 17.

Embodiment 2

[0039] Heat and melt 100 weight glycolide at 120°C, mix with 0.2 weight tetrabutyl titanate and 0.3 weight triphenyl phosphite through a static mixer, and then spray into the flow rate of 0.4L / min 180°C high-purity Nitrogen reaction After reacting in the ebullating bed for 5 minutes, the powdery polyglycolic acid resin was blown into the ebullating bed with high-purity nitrogen gas at 180°C for solid-phase viscosity-increasing reaction for 75 hours, then discharged and collected. And analyze the polyglycolic acid resin powder. The obtained polyglycolic acid resin had a weight average molecular weight Mw of 195,000, a molecular weight distribution of 2.0, and a yellowness index YI of 15.

Embodiment 3

[0041] Heat 75 weights of glycolide and 25 weights of lactide at 110°C to melt, mix with 0.3 weights of stannous octoate, 0.28 weights of triphenyl phosphite and 0.075 weights of pentaerythritol through a static mixer and spray into 0.4 The flow rate of L / min is 230°C high-purity nitrogen reaction fluidized bed. After reacting for 30 minutes, the powdered polylactide resin is blown into the 190°C high-purity nitrogen solid-phase viscosity-increasing fluidized bed for 40 hours of solid-phase increase. Discharge after viscous reaction and collect. And the polyethylene lactide resin powder was analyzed. The obtained polyethylene lactide resin had a weight average molecular weight Mw of 290,000, a molecular weight distribution of 1.6, and a yellowness index YI of 25.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| yellowness index | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com