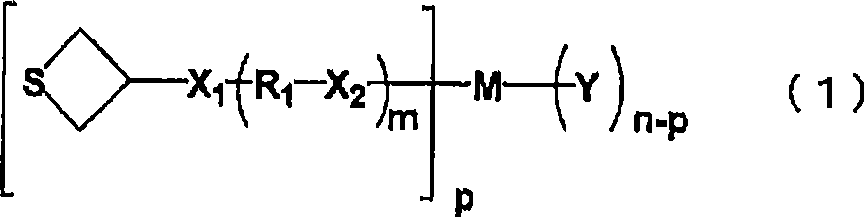

Polymerizable composition, resin using the same, optical component and lens

A polymeric composition and resin technology, applied in the field of optical components and lenses, to achieve the effect of reducing yellowness and excellent transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0382] Hereinafter, the present invention will be more specifically described by way of preparation examples and examples, but the present invention is not limited to the following examples.

[0383] In the following examples, the glass transition temperature (Tg) is measured by the TMA penetration method, and is the temperature obtained from the intersection point of the TMA curve, which corresponds to the heat deformation initiation temperature.

preparation example 1

[0385] 3-Thietanol was synthesized according to the method described in Patent Document 3 (JP-A-2003-327583).

[0386] Furthermore, using the obtained 3-thietanol, 3-mercaptothietane was synthesized. That is, 190 g of thiourea, 253 g of 35% hydrochloric acid aqueous solution, and 250 g of water were added to a reactor equipped with a stirring device and a thermometer, and 156 g of 3-thietanol was added dropwise to the stirred reaction solution over 1 hour. After stirring at 30° C. for 24 hours to react, 177 g of 24% ammonia water was added dropwise over 1 hour. After further reacting at 30° C. for 15 hours, it was left still, and the organic layer (lower layer) was taken out to obtain 134 g of a crude product. The resulting crude product was distilled under reduced pressure, and fractions with a boiling point of 40°C / 106 Pa were collected to obtain the target 3-mercaptothietane as a colorless transparent liquid.

preparation example 2

[0388] (preparation of the compound represented by CMPD. (compound) No.1-1 in the above Table 1)

[0389]11.15 g (0.105 mol) of 3-mercaptothietane was added to 50 g of pure water, and then 41.2 g (0.103 mol) of 10% NaOH aqueous solution was added dropwise at room temperature over 40 minutes. Then, the temperature of the reaction liquid was raised to 30° C., and 65.2 g (corresponding to 0.025 mol of tin tetrachloride) of a 10% tin tetrachloride aqueous solution was added dropwise over 4 hours at the same temperature. After the dropwise addition was completed, it was further stirred at the same temperature for 2 hours. 100 ml of chloroform was added to the reaction mixture, and liquid separation was performed into an organic layer and an aqueous layer. The organic layer was washed twice with 100 ml of pure water, and then dried over anhydrous sodium sulfate. The solvent was distilled off from this extract to obtain 13.40 g (yield 99%) of the compound represented by CMPD.No.1-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com