Optical film and method for producing the same

A technology of optical film and light absorption, applied in the field of optical film, can solve problems such as easy cracking, achieve low yellowness, high transparency, and improve surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0210]Hereinafter, the present invention will be described in further detail through examples. Unless otherwise stated, "%" and "part" in an example mean mass % and a mass part. First, the evaluation method will be described.

[0211]

[0212] The weight average molecular weight (Mw) of a polyamide-imide resin is measured by gel permeation chromatography (GPC), and is calculated|required by standard polystyrene conversion. Specific measurement conditions are as follows.

[0213] (1) Pretreatment method

[0214] A DMF eluent (10 mM lithium bromide solution) was added to the polyamideimide resin so that the concentration became 2 mg / mL, heated at 80° C. while stirring for 30 minutes, cooled, and then filtered with a 0.45 μm membrane filter, and the The resulting solution was used as a measurement solution.

[0215] (2) Measurement conditions

[0216] Column: TSKgel SuperAWM-H×2+SuperAW2500×1 (6.0mm I.D.×150mm×3 pieces) (both manufactured by Tosoh Corporation)

[0217] El...

manufacture example 1

[0270] [Manufacturing Example 1: Preparation of polyamideimide resin (1)]

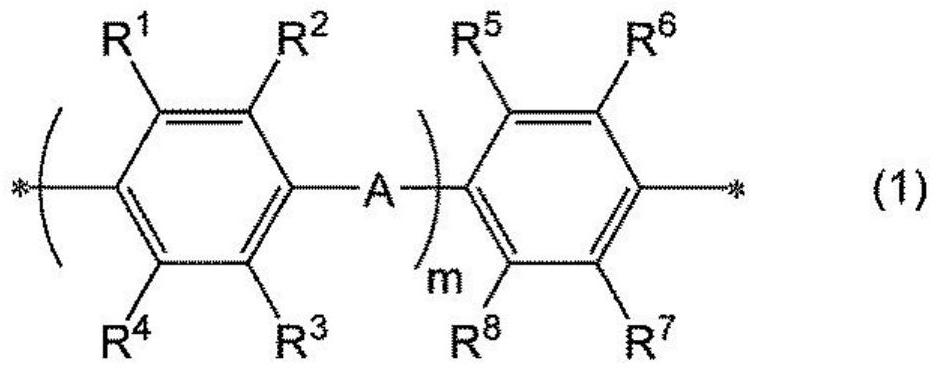

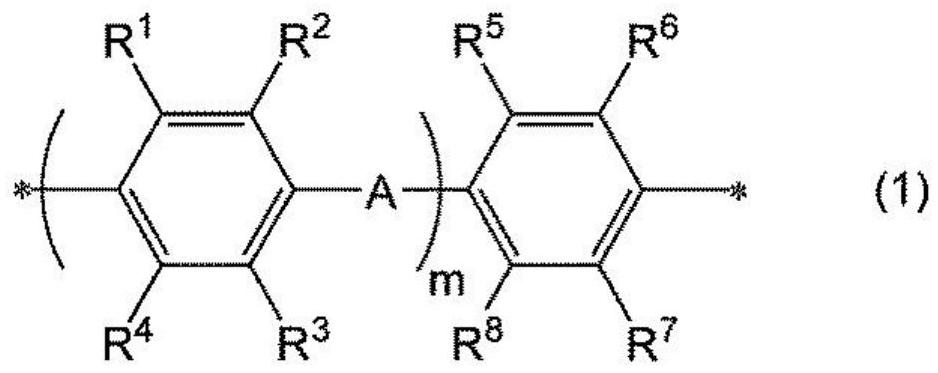

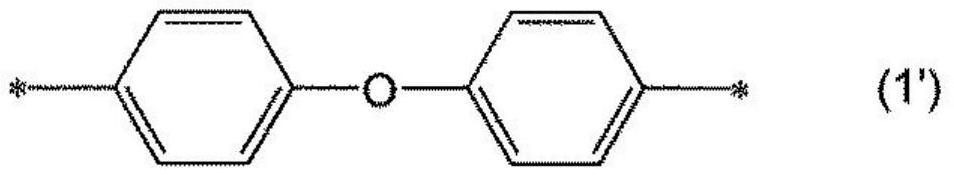

[0271] Under a nitrogen atmosphere, add 52 g (162.38 mmol) of 2,2'-bis(trifluoromethyl)benzidine (TFMB) and N,N-dimethylacetamide to a 1 L detachable flask equipped with a stirring blade (DMAc)734.10g, TFMB was dissolved in DMAc, stirring at room temperature. Next, 28.90 g (65.05 mmol) of 4,4'-(hexafluoroisopropylidene) diphthalic dianhydride (6FDA) was added to the flask, and stirred at room temperature for 3 hours. Then, 28.80 g (97.57 mmol) of 4,4'-oxybis(benzoyl chloride) (OBBC) was added to the flask, and stirred at room temperature for 1 hour.

[0272] Next, 7.49 g (94.65 mmol) of pyridine and 26.56 g (260.20 mmol) of acetic anhydride were added to the flask, stirred at room temperature for 30 minutes, then raised to 70° C. using an oil bath, and stirred for a further 3 hours to obtain a reaction liquid.

[0273]The obtained reaction liquid was cooled to room temperature, and it was poured int...

Embodiment 1

[0274] [Example 1: Formation of polyamide-imide film (1)]

[0275] To the polyamide-imide resin (1) obtained in manufacture example 1, DMAc was added so that the density|concentration might become 15 mass %, and the polyamide-imide varnish (1) was produced. Using an applicator, the obtained polyamideimide varnish (1) was applied to the smooth surface of a polyester substrate (trade name "A4100" manufactured by Toyobo) so that the film thickness of the self-supporting film became 55 μm. Drying was carried out at 50° C. for 30 minutes, followed by drying at 140° C. for 15 minutes. Then, the obtained coating film was peeled from the polyester substrate to obtain a self-supporting film.

[0276] The self-supporting film was fixed to a metal frame, and further dried at 230° C. for 30 minutes in the atmosphere to obtain a polyamide-imide film (1) having a thickness of 50 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com