A multifunctional screen protector

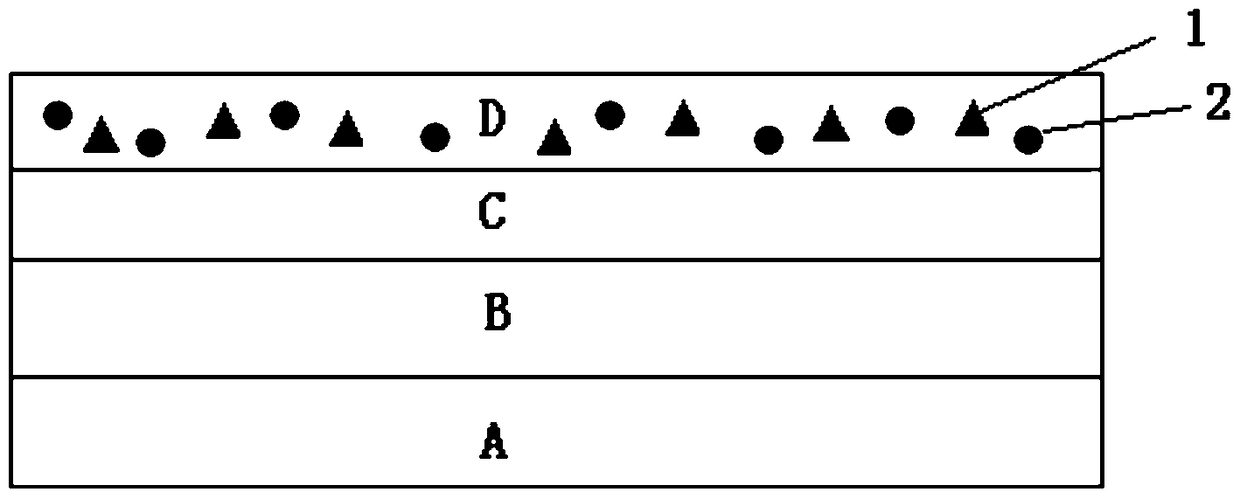

A screen protective film and multi-functional technology, applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc. Static and anti-Newton rings and other issues, to achieve the effect of good adhesion, simple structure, easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

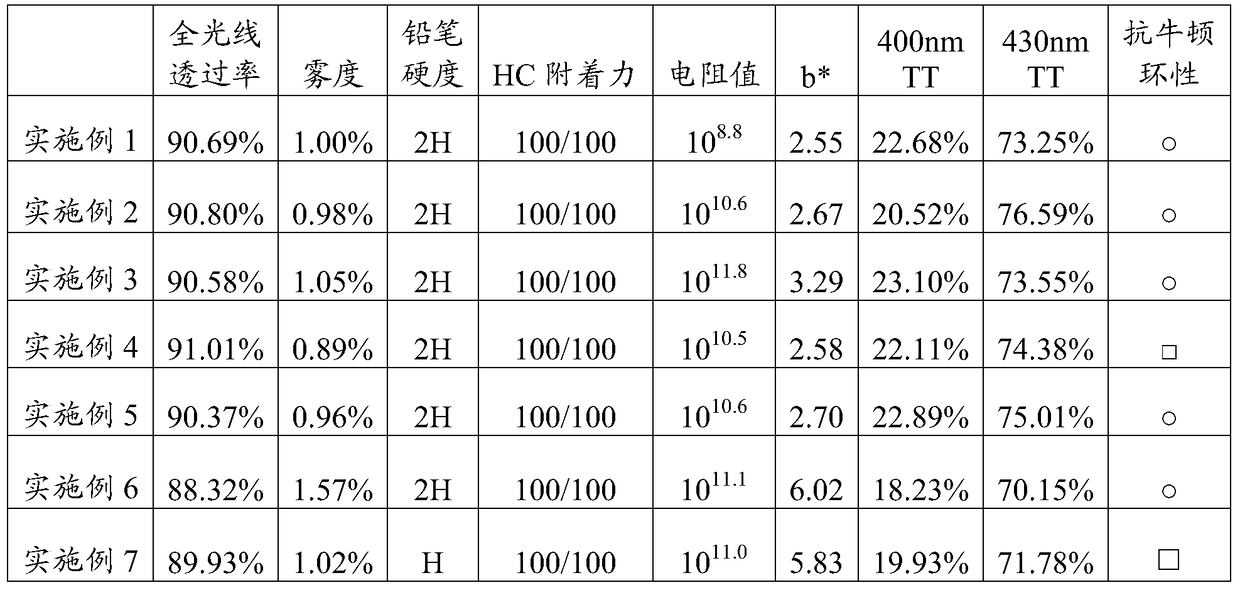

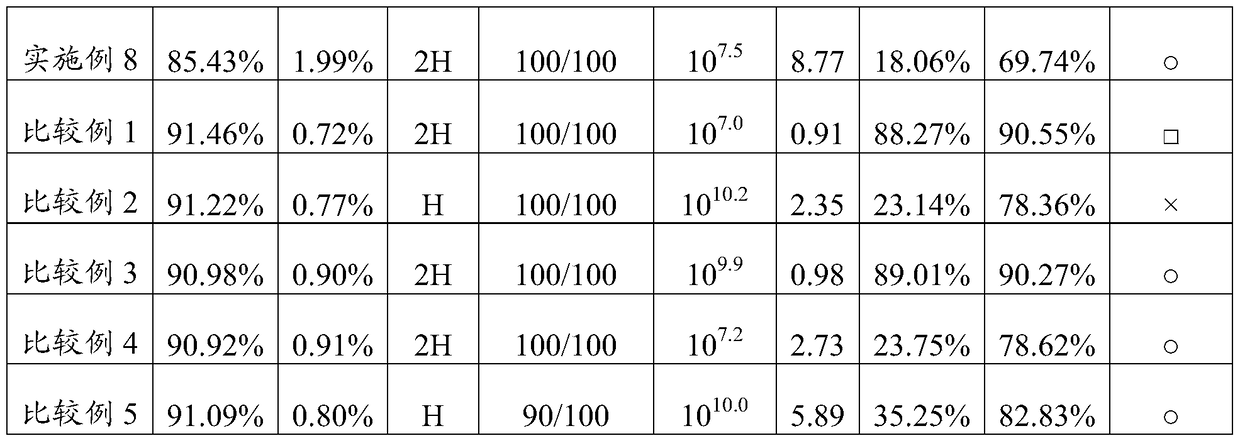

Examples

Embodiment 1

[0050] Dissolve 5g of antistatic agent EF-N115 and 3g of EVERSORB type anti-blue light agent with methyl ethyl ketone, then add 50g of UV curable resin FB003 to it, and dilute to a coating solution with a solid content of 30%. The coating solution was coated on a transparent PET substrate, placed in a circulating oven at 80°C for 2 minutes, and then passed through a dose of 500mJ / cm 2 irradiated with ultraviolet light to obtain a multifunctional film layer attached to the substrate layer. Then coat a layer of OCA adhesive layer on the back and cover a layer of release film to get a multi-functional screen protective film. Among them, the thickness of the multifunctional layer is 3 μm, the thickness of the PET base layer is 100 μm, the thickness of the optical adhesive layer is 50 μm, and the thickness of the release film layer is 50 μm.

Embodiment 2

[0052] Dissolve 10g of antistatic agent EF-N115 and 3g of EVERSORB type anti-blue light agent in ethyl acetate, then add 50g of UV-curable resin FB003 to it, and dilute to a coating solution with a solid content of 30%. The coating solution was coated on a transparent PC substrate, dried in a circulating oven at 80°C for 2 minutes, and then passed through a dose of 500mJ / cm 2 UV light irradiation to obtain a multifunctional film attached to the substrate layer. Then coat a layer of OCA adhesive layer on the back and cover a layer of release film to get a multi-functional screen protective film. Among them, the thickness of the multifunctional layer is 3 μm, the thickness of the PET base layer is 100 μm, the thickness of the optical adhesive layer is 50 μm, and the thickness of the release film layer is 50 μm.

Embodiment 3

[0054] Dissolve 10g of antistatic agent EF-N115 and 5g of EVERSORB type anti-blue light agent in methyl ethyl ketone, then add 50g of UV-curable resin FB003 to it, and dilute to a coating solution with a solid content of about 30%. The coating solution was coated on a transparent PET substrate, dried in a circulating oven at 80°C for 4 minutes, and then passed through a dose of 500mJ / cm 2 UV light irradiation to obtain a multifunctional film attached to the substrate layer. Then coat a layer of OCA adhesive layer on the back and cover a layer of release film to get a multi-functional screen protective film. Among them, the thickness of the multifunctional layer is 3 μm, the thickness of the PET base layer is 100 μm, the thickness of the optical adhesive layer is 50 μm, and the thickness of the release film layer is 50 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com