2, 5-furan dicarboxylic polyester/layered silicate nano-composite material, preparation method thereof and application of material

A technology of nano-composite materials and furandicarboxylic acid diester, which is applied in the field of polymer materials, can solve the problems of increasing molecular weight, insufficient effect, low molecular weight, etc., and achieve good tensile strength, simple and feasible method, and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

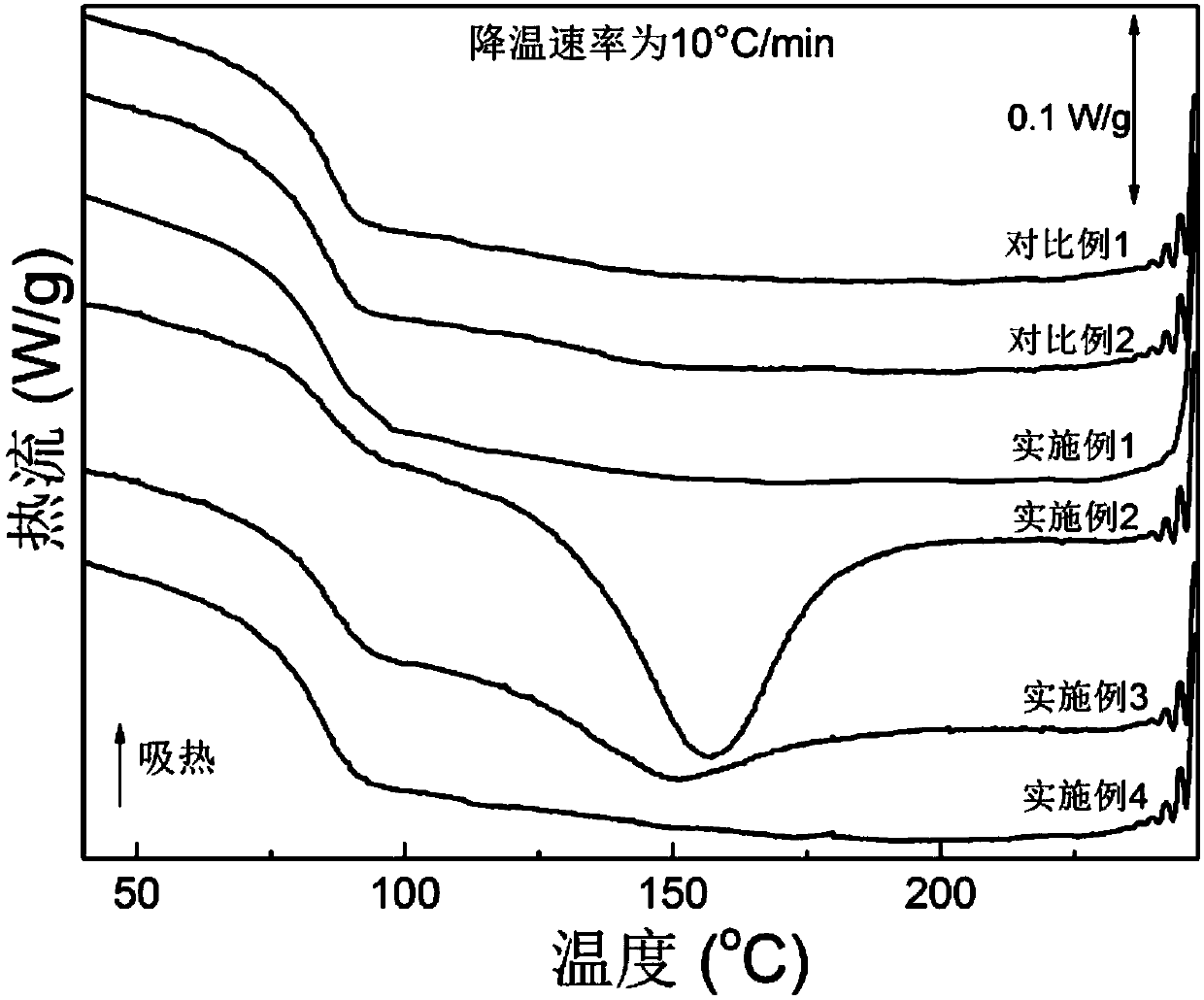

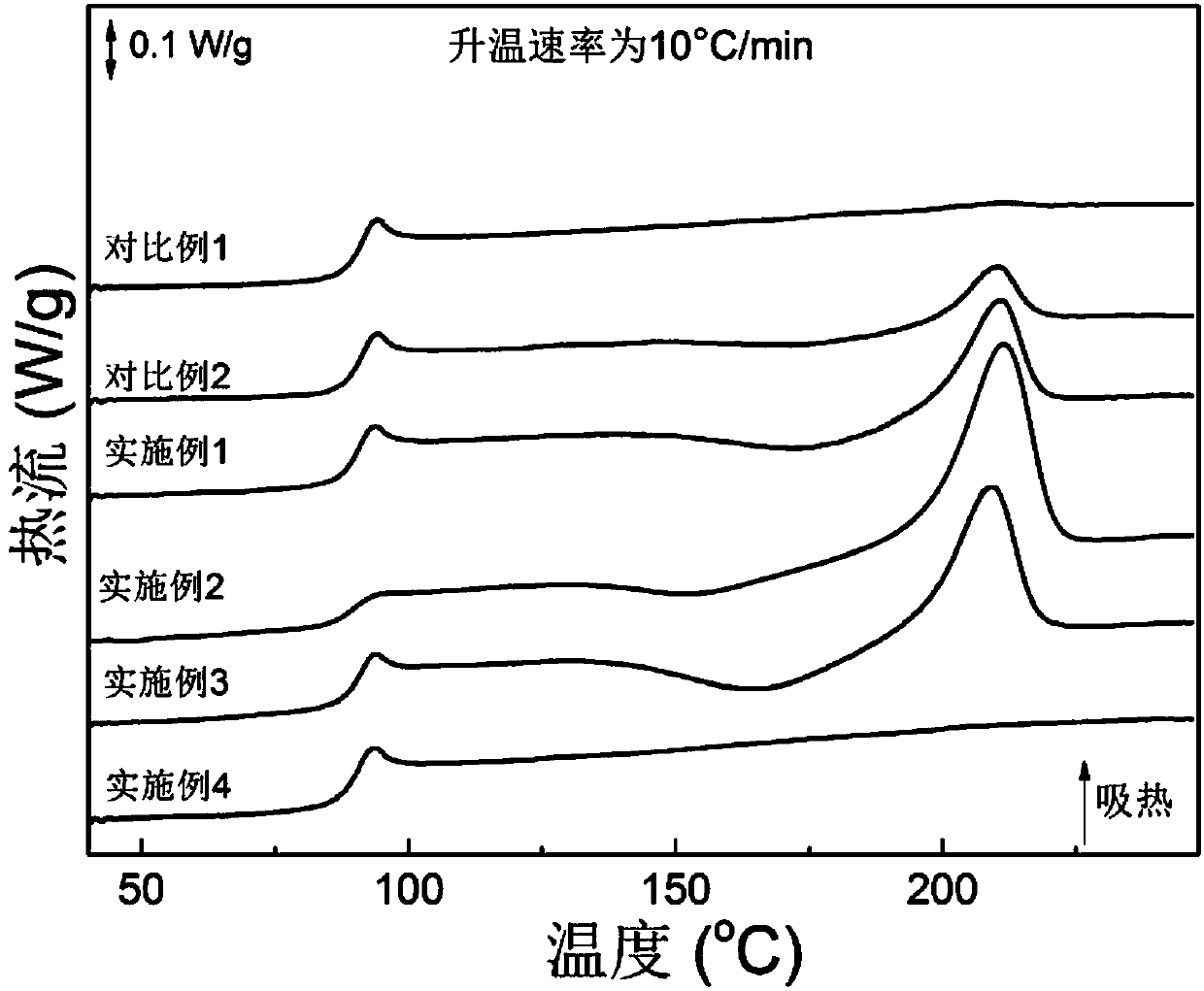

Embodiment 1

[0049] (1) Mix 0.67g of dried montmorillonite modified with octadecylbishydroxyethylmethylammonium salt with 44.67g of ethylene glycol, stir vigorously for 2 hours, and disperse in an ultrasonic environment for 15 minutes , to obtain an ethylene glycol suspension containing montmorillonite treated with octadecylbishydroxyethylmethylammonium salt;

[0050] (2) Under a nitrogen atmosphere, add the ethylene glycol suspension obtained in step (1), 66.28g dimethyl 2,5-furandicarboxylate and 0.08g stannous oxalate to the reactor, and react at 170°C for 1 hour , react at 180°C for 1 hour, react at 190°C for 1 hour, and react at 200°C for 1 hour to obtain the transesterified product;

[0051] (3) Add 0.1 g of ethylene glycol antimony to the transesterified product obtained in step (2), and conduct polycondensation at 240°C and high vacuum (≦133Pa) for 3 hours to obtain poly-2,5-furandicarboxylic acid Ethylene glycol ester / organic montmorillonite nanocomposite material, the amount of ...

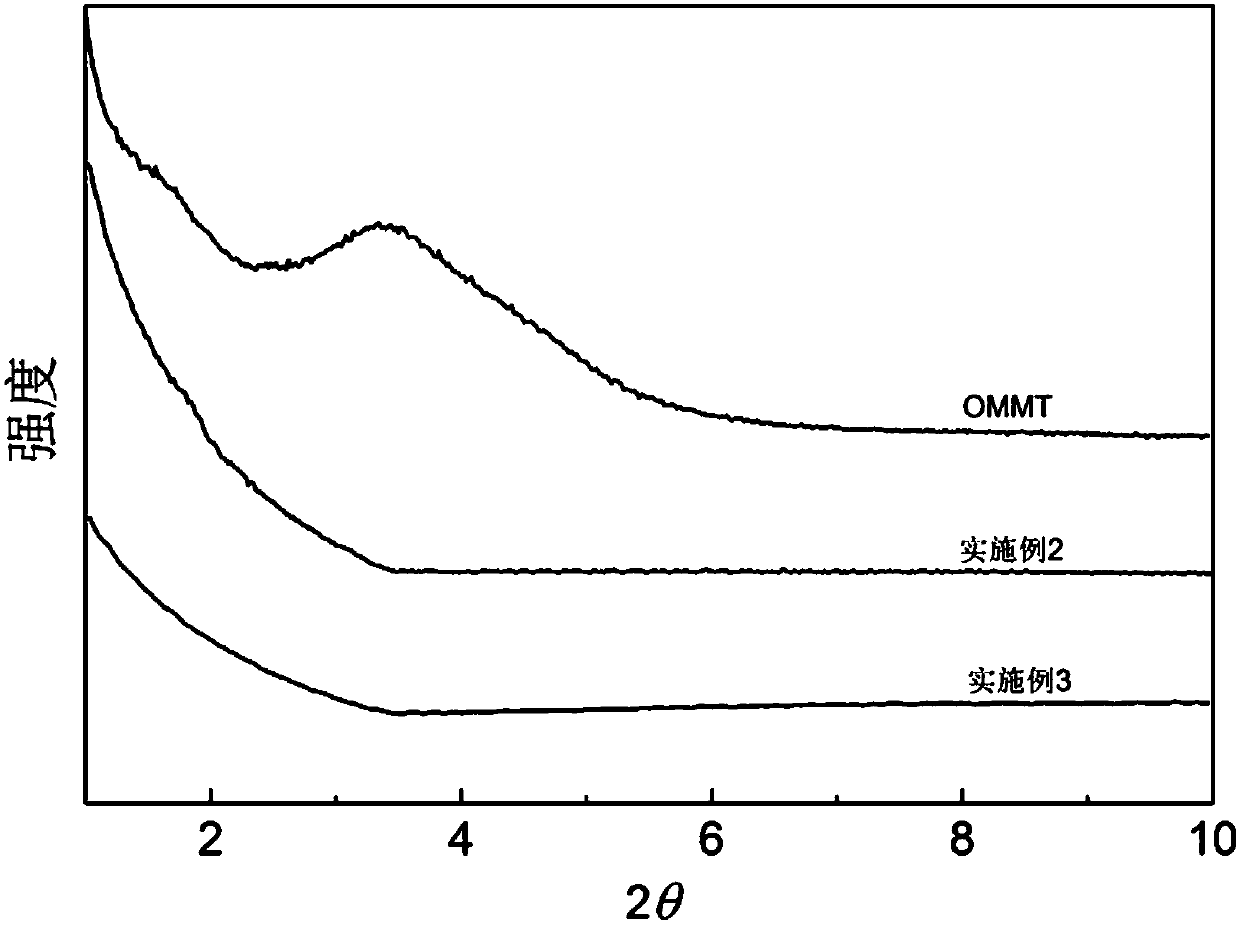

Embodiment 2

[0053] (1) Mix the dried 1.66g of montmorillonite modified with octadecylbishydroxyethylmethyl with 44.67g of ethylene glycol, stir vigorously for 2 hours and then disperse in an ultrasonic environment for 15 minutes to prepare Obtain the ethylene glycol suspension containing the montmorillonite modified by octadecyl bis-hydroxyethyl methyl ammonium salt;

[0054] (2) Under a nitrogen atmosphere, add the ethylene glycol suspension obtained in step (1), 66.28g dimethyl 2,5-furandicarboxylate and 0.08g stannous oxalate to the reactor, and react at 170°C for 1 hour , react at 180°C for 1 hour, react at 190°C for 1 hour, and react at 200°C for 1 hour to obtain the transesterified product;

[0055] (3) Add 0.1 g of ethylene glycol antimony to the transesterified product obtained in step (2), and conduct polycondensation at 240°C and high vacuum (≦133Pa) for 3 hours to obtain poly-2,5-furandicarboxylic acid Ethylene glycol ester / organic montmorillonite nanocomposite material, the a...

Embodiment 3

[0057] (1) 2.32g of dried montmorillonite and 44.67g of ethylene glycol were mixed through 18-bishydroxyethylmethyl ammonium salt modification, stirred vigorously for 2 hours and then dispersed in an ultrasonic environment for 15 minutes to prepare Obtain the ethylene glycol suspension containing the montmorillonite modified by octadecyl bis-hydroxyethyl methyl ammonium salt;

[0058] (2) Under a nitrogen atmosphere, add the ethylene glycol suspension obtained in step (1), 66.28g dimethyl 2,5-furandicarboxylate and 0.08g stannous oxalate to the reactor, and react at 170°C for 1 hour , react at 180°C for 1 hour, react at 190°C for 1 hour, and react at 200°C for 1 hour to obtain the transesterified product;

[0059] (3) Add 0.1 g of ethylene glycol antimony to the transesterification product obtained in step (2), and conduct polycondensation at 240°C and high vacuum (≦133Pa) for 3 hours to obtain poly-2,5-furandicarboxylic acid Ethylene glycol ester / organic montmorillonite nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com