Preparation method of degradable glycolic acid copolyester

A technology of glycolic acid copolyester and glycolic acid, which is applied in the field of polymer materials, can solve the problems of poor thermal stability of copolymers, low intrinsic viscosity of products, excessive degradation speed, etc., and achieve low production energy consumption and low production cost. Low, the effect of less side effects in the whole process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

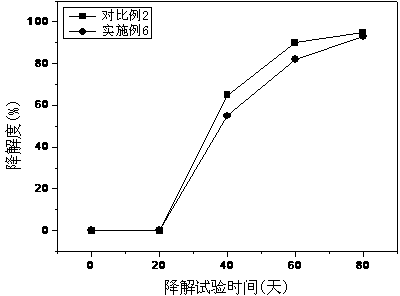

Image

Examples

Embodiment 1

[0019] A kind of preparation method of degradable glycolic acid copolyester, preparation steps are as follows: 10mol glycolic acid, 0.05mol adipic acid and 0.045mol ethylene glycol are added in the reactor, add precondensation catalyst 0.038g zinc powder to carry out pretreatment Polycondensation reaction, the precondensation reaction temperature is 100°C, the stirring speed is 5r / min, the precondensation reaction time is 2h, and the precondensation product is obtained; 0.038g of polycondensation catalyst bismuth acetate and 0.0076g of stabilizer phosphoric acid are added to the precondensation product The polycondensation reaction of triphenyl ester is carried out, the stirring speed is 5r / min, the temperature of polycondensation reaction is 170°C, the reaction time is 1h, and the reaction vacuum is 0.1mmHg, and the glycolic acid copolyester with medium molecular weight is obtained. After testing, the glycolic acid copolyester The intrinsic viscosity number of polyester is 0.8...

Embodiment 2

[0021] A kind of preparation method of degradable glycolic acid copolyester, preparation steps are as follows: 10mol glycolic acid, 0.1mol adipic acid and 0.12mol ethylene glycol are added in the reactor, add precondensation catalyst 0.08g tetraisotitanate Propyl ester and 0.02g tetrabutyl titanate were subjected to precondensation reaction, the precondensation reaction temperature was 120°C, the stirring speed was 50r / min, the precondensation reaction time was 4h, and the precondensation product was obtained; 0.18g The polycondensation catalyst antimony acetate and 0.01g stabilizer triphenyl phosphate were used for polycondensation reaction, the stirring speed was 50r / min, the temperature of polycondensation reaction was 190°C, the reaction time was 3h, and the reaction vacuum was 1mmHg to obtain medium molecular weight Glycolic acid copolyester, after testing, the intrinsic viscosity of glycolic acid copolyester is 0.87dl / g; Glycolic acid copolyester produced by polycondensat...

Embodiment 3

[0023]A kind of preparation method of degradable glycolic acid copolyester, preparation steps are as follows: 10mol glycolic acid, 1mol adipic acid and 1.3mol ethylene glycol are joined in the reactor, add precondensation catalyst 0.2g ethylene glycol titanium, 0.6g of titanium butoxide and 0.3g of titanium dioxide were subjected to precondensation reaction, the precondensation reaction temperature was 140°C, the stirring speed was 80r / min, and the precondensation reaction time was 8h to obtain a precondensation product; add 0.9g to the precondensation product The polycondensation catalyst tetraisopropyl titanate and 0.2g stabilizer triphenyl phosphite were used for polycondensation reaction, the stirring speed was 80r / min, the temperature of polycondensation reaction was 200°C, the reaction time was 5h, and the reaction vacuum was 3mmHg. Make the glycolic acid copolyester of medium molecular weight, the intrinsic viscosity number of glycolic acid copolyester is 0.76dl / g throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com