Method for preparing poly-oxalate-1,4-butylene

A technology of butanediol ester and diethyl oxalate, applied in the field of polyoxalic acid-1, can solve problems such as high cost and long reaction time, and achieve the effects of low cost, simple operation and reduction of reaction vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Weigh respectively 0.5mol of diethyl oxalate (73.07g), 0.5mol of 1,4-butanediol (45.06g) and 0.005mol of sodium methoxide, add in a 500ml three-necked round-bottomed flask, pass into N 2 , the flow rate is 0.1m 3 / h, heated in an oil bath to control the reaction temperature at 140°C, stirred mechanically, and the reactants were completely melted. When the reaction temperature rose to 140°C, the timing was started, and the reaction was carried out at a constant temperature for 5 hours. The obtained product was a dark white solid with an intrinsic viscosity of 0.04dL / g.

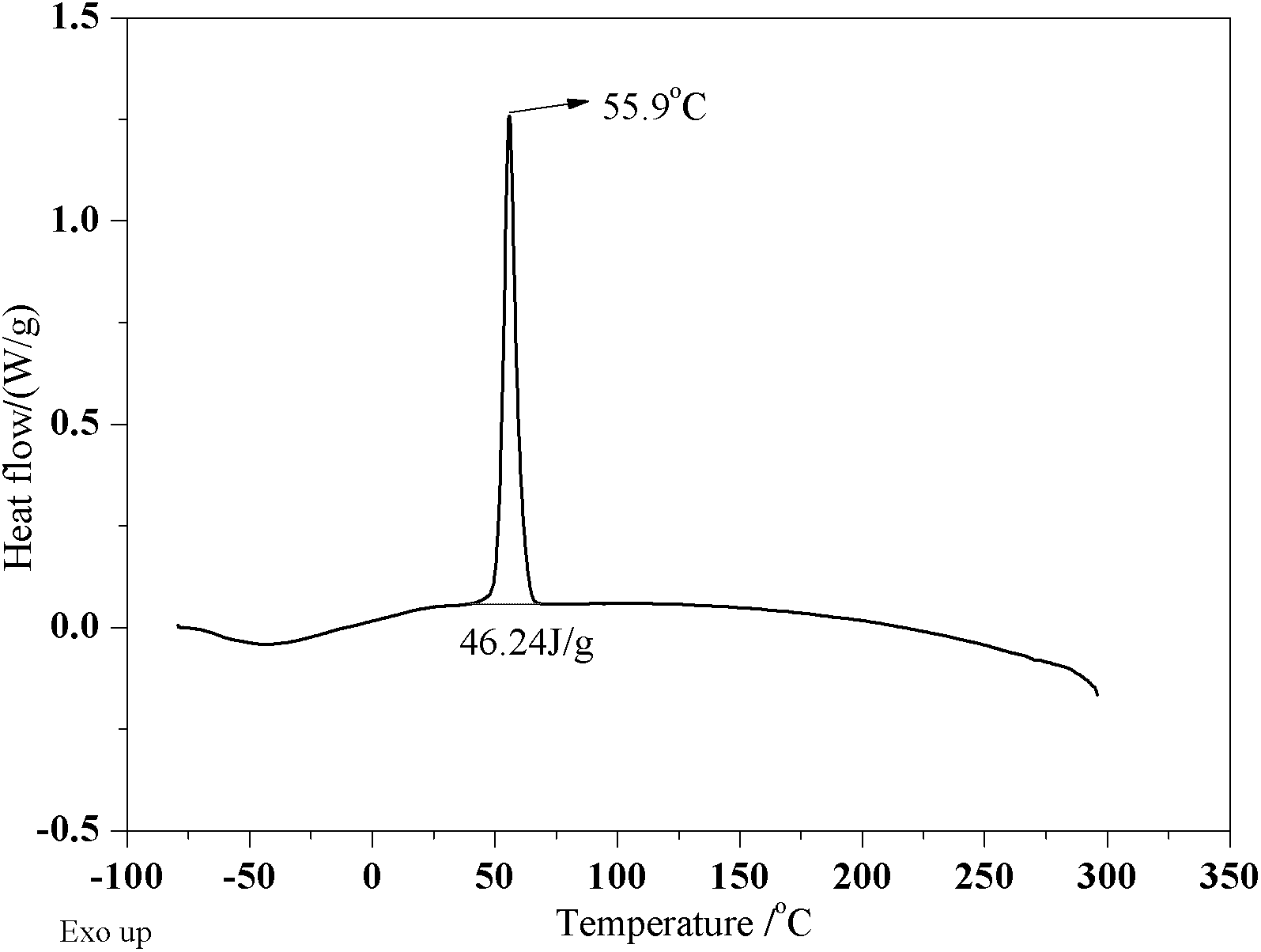

[0037] figure 1 The crystallization curve in the DSC spectrogram of the poly-1,4-butanediol oxalate prepared for the present embodiment is obtained by figure 1 It can be seen that the crystallization temperature of the product of this example is 55.9°C.

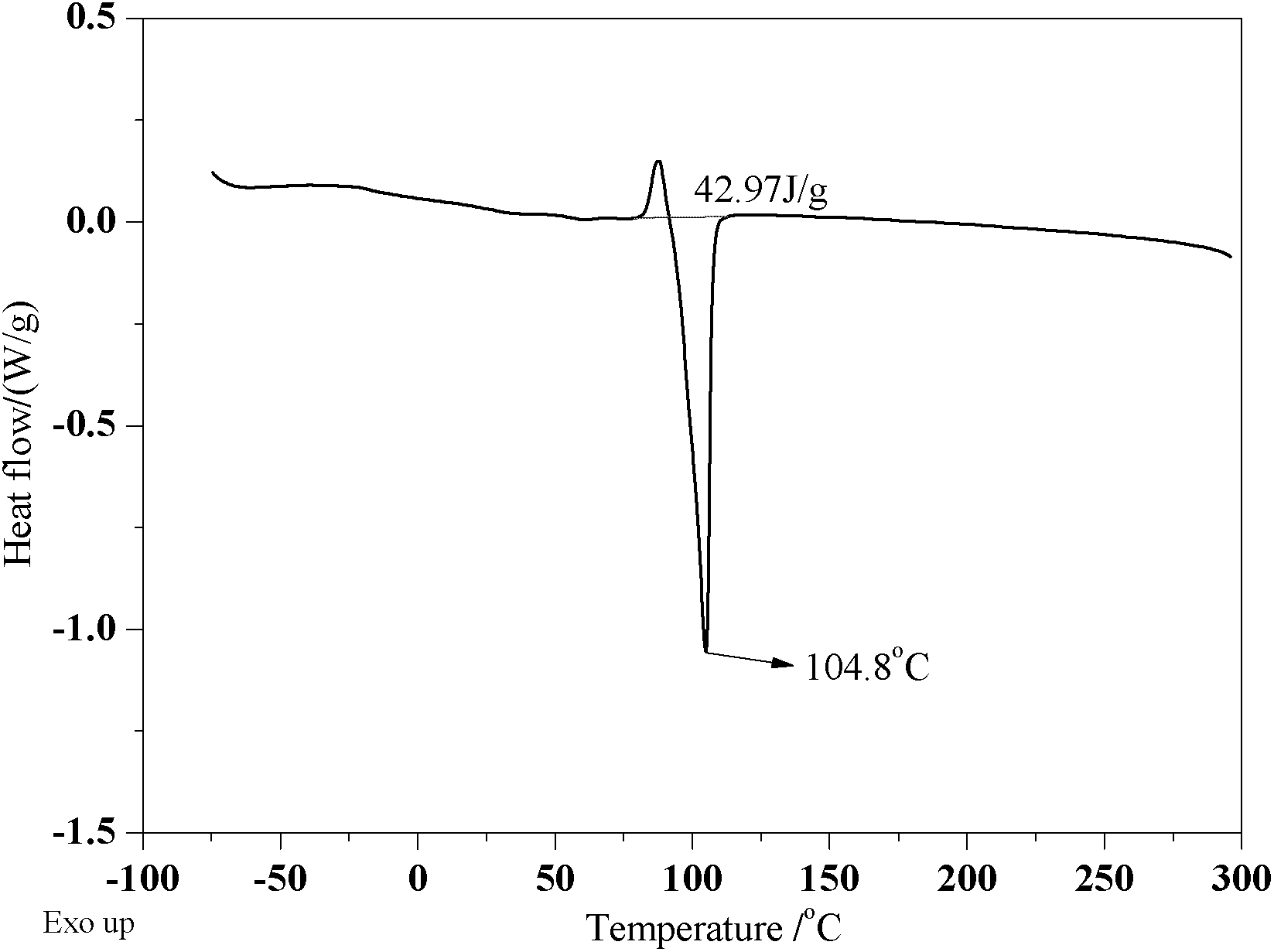

[0038] figure 2 The melting curve in the DSC spectrogram of the poly-1,4-butanediol oxalate prepared for the present embodiment is obtained by fi...

Embodiment 2

[0043] Weigh 0.5mol of diethyl oxalate, 0.5mol of 1,4-butanediol and 0.005mol of NaOH respectively, add them to a 500ml three-necked round-bottomed flask, and inject N 2 , the flow rate is 0.1m 3 / h, heating in an oil bath to control the reaction temperature at 140°C, stirring mechanically, the reactants are completely melted, when the reaction temperature rises to 140°C, start timing, and react at a constant temperature for 5h, and the product obtained is poly-1,4-butylene oxalate. It is a dark white solid with an intrinsic viscosity of 0.04dL / g.

Embodiment 3

[0045] Weigh respectively 0.5mol of diethyl oxalate, 0.5mol of 1,4-butanediol and 0.005mol of KOH, add to a 500ml three-necked round-bottomed flask, and inject N 2 , the flow rate is 0.1m 3 / h, heating in an oil bath to control the reaction temperature at 140°C, stirring mechanically, the reactants are completely melted, when the reaction temperature rises to 140°C, start timing, and react at a constant temperature for 5h, and the product obtained is poly-1,4-butylene oxalate. It is a dark white solid with an intrinsic viscosity of 0.06dL / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com