Aliphatic polyester ionic polymer and preparation method thereof

A technology of aliphatic polyester and ionomer, applied in the field of aliphatic polyester ionomer and its preparation, can solve the problems of poor tear resistance, difficult polymerization reaction, preparation of film products, etc., and achieve excellent blow molding properties, low shear thinning effect, and increased melt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

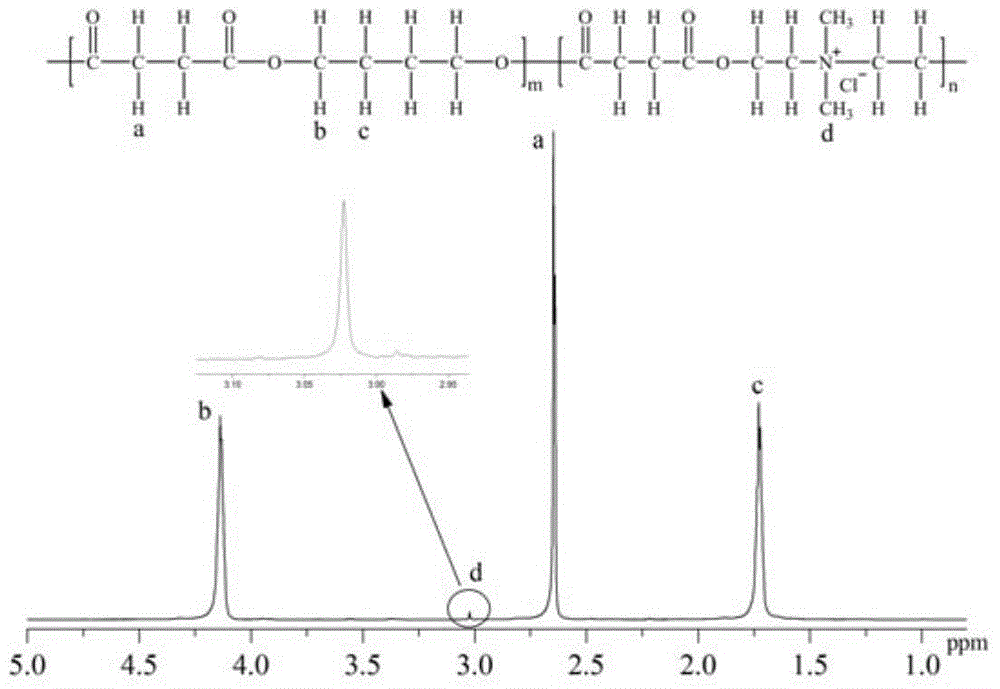

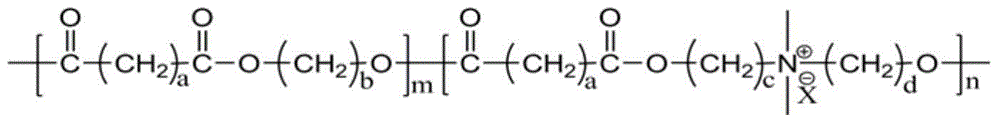

[0029]Add succinic acid, butanediol and N,N,-dimethyl-N,N-dihydroxyethylammonium chloride into the reaction device at a molar ratio of 100:99.7:0.3, and esterify at 180°C under nitrogen protection reaction for 4 hours, then add 0.1% tetrabutyl titanate based on the total mass of the reactants, conduct polycondensation reaction at 220°C and ≤30Pa high vacuum conditions for 3 hours, and then discharge.

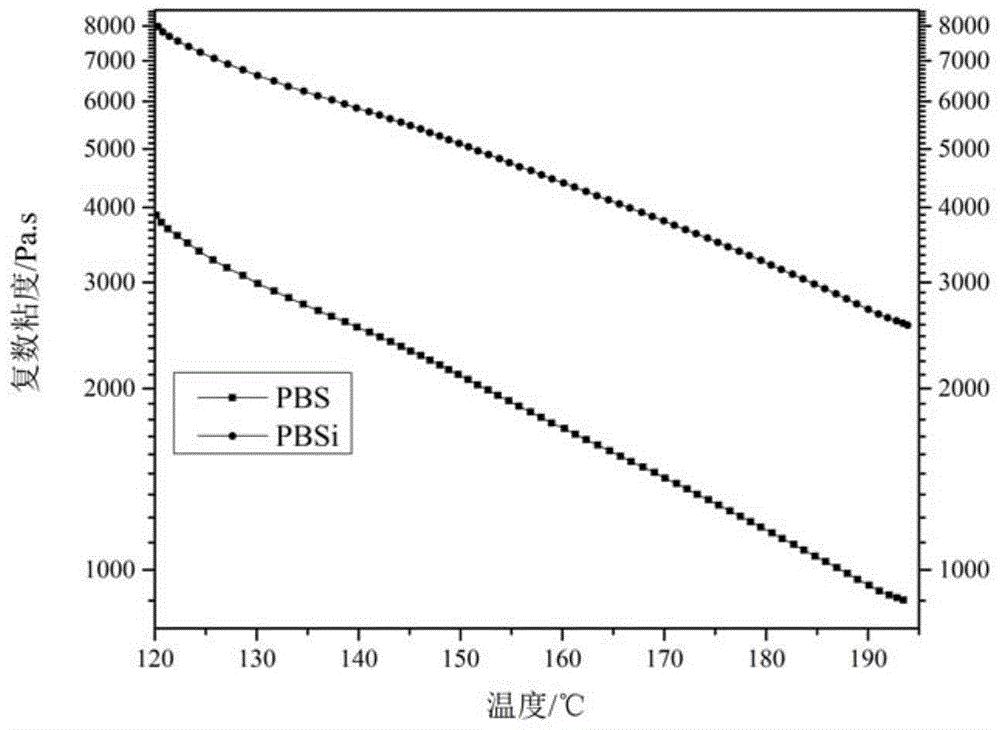

[0030] The intrinsic viscosity of the obtained aliphatic polyester ionomer is 1.5dL / g, and the complex viscosity is the complex number of pure aliphatic polyester (without quaternary ammonium salt ion monomer) at any specified temperature of 120-200°C. 2 to 3 times the viscosity value.

Embodiment 2

[0032] Add adipic acid, ethylene glycol and N,N,-dimethyl-N-hydroxyethyl-N-hydroxypropylammonium chloride into the reaction device at a molar ratio of 100:99:1, and under nitrogen protection, Esterification reaction at 150°C for 3 hours, then adding 0.01% tetraisopropyl titanate based on the total mass of the reactants, polycondensation reaction at 200°C, ≤30Pa high vacuum conditions for 4 hours, and then discharging.

[0033] The intrinsic viscosity of the obtained aliphatic polyester ionomer is 1.6dL / g, and the complex viscosity is the complex number of pure aliphatic polyester (without quaternary ammonium salt ion monomer) at any specified temperature of 120-200°C. 1.9 to 2.6 times the viscosity value.

Embodiment 3

[0035] Add malonic acid, pentanediol and N,N,-dimethyl-N-hydroxyethyl-N-hydroxybutylammonium bromide into the reaction device at a molar ratio of 100:97:3, and under nitrogen protection, Esterification reaction at 160°C for 3.5 hours, then adding 0.03% stannous chloride based on the total mass of reactants, polycondensation reaction at 220°C, ≤30Pa high vacuum conditions for 6 hours, and then discharging.

[0036] The intrinsic viscosity of the obtained aliphatic polyester ionomer is 1.8dL / g, and the complex viscosity is the complex number of pure aliphatic polyester (without quaternary ammonium salt ion monomer) at any specified temperature of 120-200°C. 1.8 to 2.5 times the viscosity value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com