PET (polyethylene terephthalate) composite for producing thermal aging resistant insulating film and preparation method of PET compound

A heat-resistant aging, insulating film technology, applied in the field of polyester film manufacturing, can solve the problem of affecting the PET molecular chain structure and insulating film biaxial stretching production process insulating film surface flatness, gloss, electrical insulation properties, mechanical properties , Antioxidant, heat stabilizer and nucleating agent are not easy to disperse uniformly, and the heat resistance effect of PET insulating film is not obvious enough to achieve the effect of improving thermal aging behavior, improving mechanical properties and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

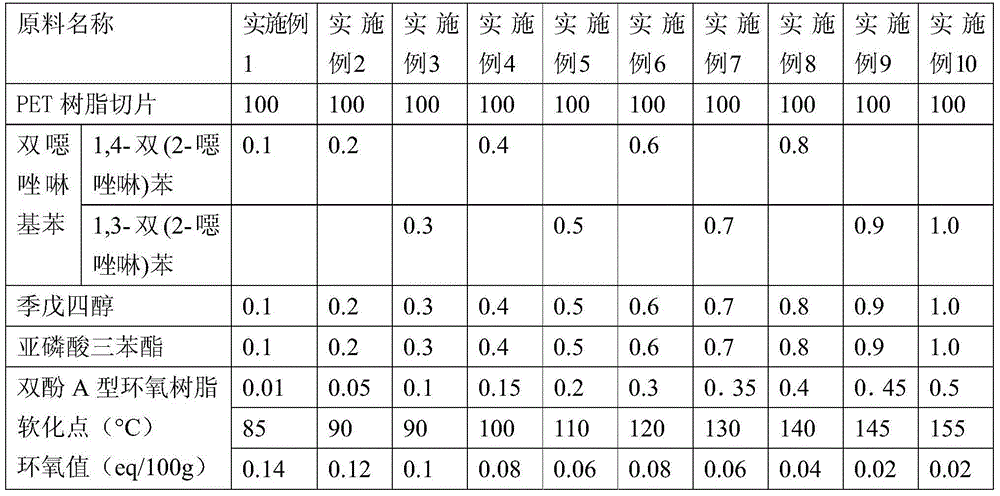

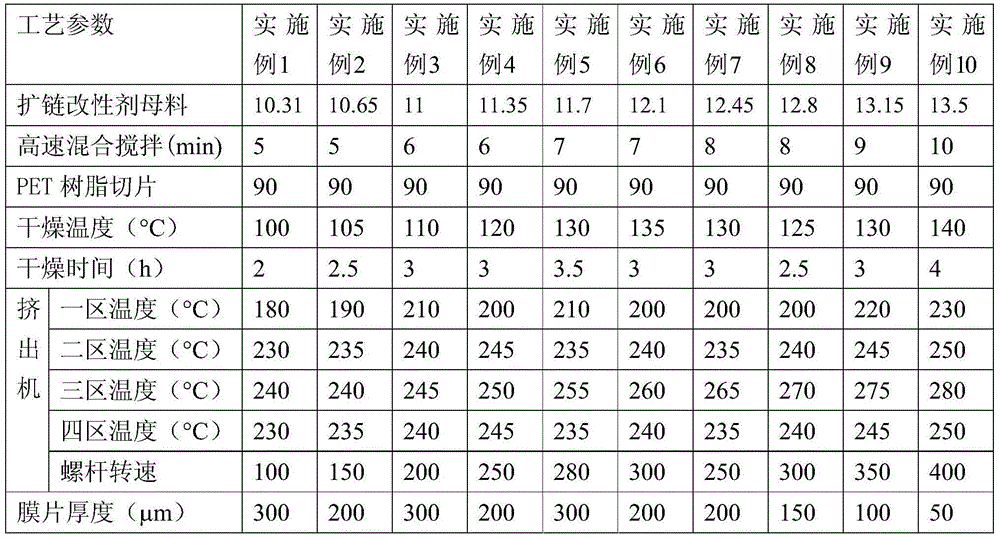

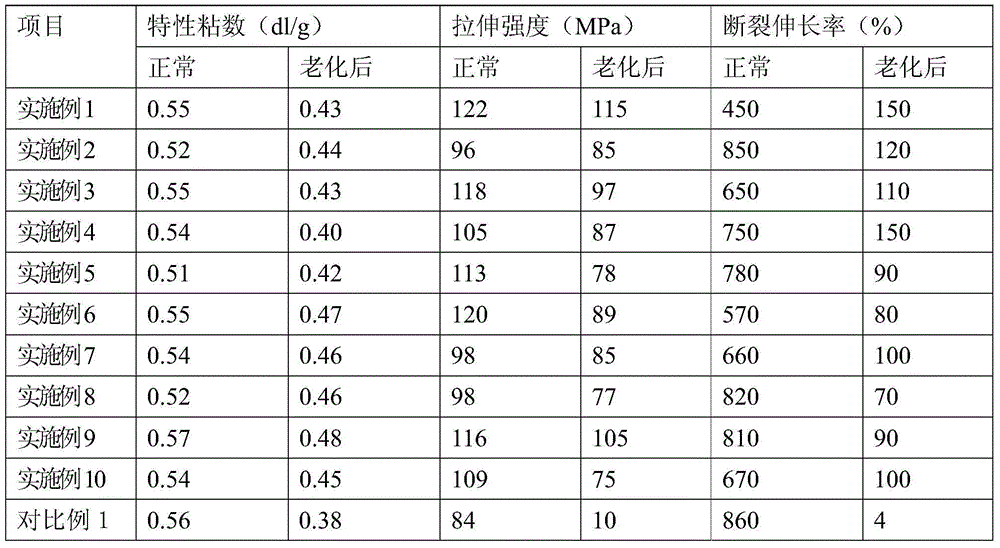

[0018] The PET composite used for the production of heat-resistant aging insulation film of the present invention has a raw material composition comprising 100 parts by mass of PET chips, 0.1-1.0 parts of bisoxazoline benzene, 0.1-1.0 parts of pentaerythritol, and 0.1 parts by mass. ~1.0 part of triphenyl phosphite, 0.01-0.50 part of bisphenol A epoxy resin, among which the softening point of bisphenol A epoxy resin is 85-155℃, and the epoxy value is 0.02-0.14eq / 100g, and the bisoxazolinylbenzene is 1,4-bis(2-oxazoline)benzene or 1,3-bis(2-oxazoline)benzene. The present invention uses bisoxazolinylbenzene and triphenyl phosphite as melt processing chain extenders to improve mechanical properties, and at the same time mixes a small amount of pentaerythritol and a small amount of high molecular weight bisphenol A epoxy resin as viscosity regulators. By controlling the molecular structure and crystallization behavior of PET, it can reduce the high-temperature degradation rate of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com