Method for preparing polytrimethylene terephthalate

The technology of polytrimethylene terephthalate and terephthalic acid is applied in the field of preparation of polytrimethylene terephthalate, and can solve the problems of high content of terminal carboxyl group and acrolein, poor stability, yellowing of products, etc. Low content of terminal carboxyl group, high stability and good color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

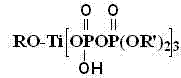

[0023] 1. Preparation of nano-tetrabutyl titanate / nano-silica supported catalyst

[0024] Take 0.6g of hydrophilic nano-silica and place it in the flask, add 10mL of oleic acid and 300mL of toluene, stir evenly and ultrasonically disperse, then add 0.2g of isopropyl tris(dioctyl pyrophosphate acyloxy) titanic acid The ester was treated in a water bath at 90℃ for 2h; then the toluene was removed by rotary evaporation, washed three times with ether and then dried and ground; the ground modified nano-silica and 0.3g of tetrabutyl titanate were placed in 250ml of dry toluene with 90Hz ultrasound Shake for 30min to disperse evenly, soak for 1d at room temperature; wash and dry after centrifugal separation.

[0025] 2. Synthesis of Polytrimethylene Terephthalate (PTT)

[0026] Weigh the raw materials according to the molar ratio of terephthalic acid and 1,3-propanediol 1:1.5 and place them in the polymerizer, and place it in the polymerizer at 5×10 of the molar amount of terephthalic acid...

Embodiment 2

[0029] Same as Example 1, the difference is:

[0030] The amount of catalyst in step (2) is 7×10 of the molar amount of terephthalic acid -4 .

[0031] The content of terminal carboxyl group is determined to be 18.237mol / t, and the intrinsic viscosity is 1.05 dL / g -1 , Get white PPT resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com