Macromolecular drag reducer, preparation method and application thereof

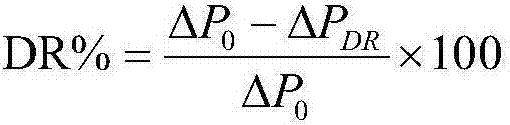

A drag reducing agent and polymer technology, applied in the field of polymer drag reducing agent and its preparation, can solve the problems of difficult addition method, uneconomical and practical, large amount of surfactant, etc., and achieve good drag reducing effect, low cost, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

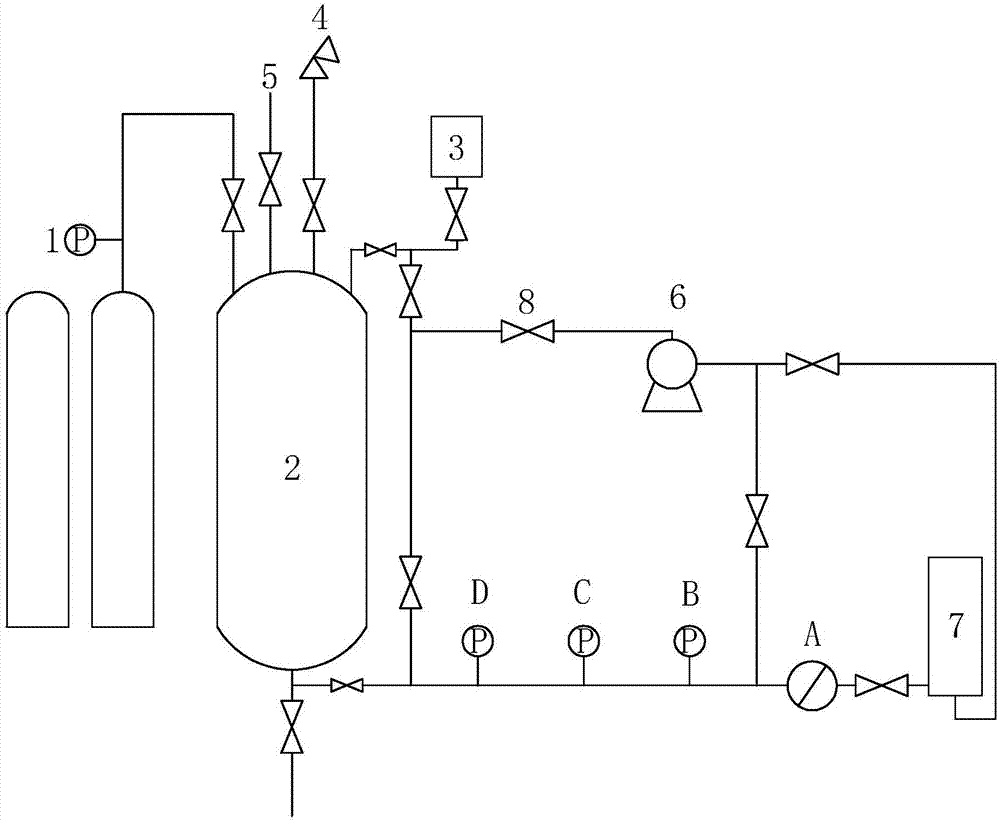

Method used

Image

Examples

Embodiment 1

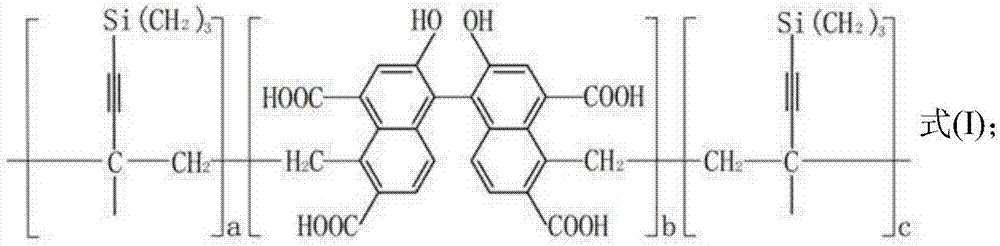

[0032] Preparation of the polymer compound described in formula (I): 1Kg of 4,4',6,6'-tetracarboxy-1,1'-binaphthol and 10Kg of 2-methyl-4-trimethylsilane Base-1-buten-3-yne, 2Kg of formaldehyde and 20Kg of propanol are mixed, add the initiator system (0.025Kg of ammonium sulfate is adsorbed on 0.125Kg of graphite), at a pressure of 0.7MPa, a temperature of 110 The reaction was carried out under the condition of ℃ for 60 minutes, and after the reaction was completed, the temperature was lowered to normal temperature, and the volatile substances were removed to obtain the polymer compound described in formula (I).

[0033] Preparation of polymer drag reducer: under the condition of argon protection, the polymer compound described in the formula (I) of 3Kg, the α-decene of 10Kg, the triethylaluminum of 0.115Kg and the diphenyl silicone oil of 3Kg Stir and mix, and lower the temperature to 10° C.; then add 0.385 Kg of titanium trichloride, and conduct a polymerization reaction at ...

Embodiment 2

[0035]Preparation of the polymer compound described in formula (I): 1Kg of 4,4',6,6'-tetracarboxy-1,1'-binaphthol and 15Kg of 2-methyl-4-trimethylsilane Base-1-buten-3-yne, 1.8Kg of formaldehyde and 30Kg of ethanol are mixed, add the initiator system (0.04Kg of ammonium sulfate is adsorbed on 0.06Kg of graphite), and the pressure is 1.0MPa, the temperature is 105 The reaction was carried out under the condition of ℃ for 30 minutes, and after the completion of the reaction, the temperature was lowered to normal temperature, and the volatile substances were removed to obtain the polymer compound described in formula (I).

[0036] Preparation of polymer drag reducer: under the condition of helium protection, the polymer compound described in the formula (I) of 2Kg, the α-nonene of 10Kg, the triisobutylaluminum of 0.334Kg and the silicone oil of 5Kg are stirred and mixed , and the temperature was lowered to -10°C; then 0.667Kg of titanium tetrachloride was added, and the polymeriz...

Embodiment 3

[0038] Preparation of the polymer compound described in formula (I): 1Kg of 4,4',6,6'-tetracarboxy-1,1'-binaphthol and 20Kg of 2-methyl-4-trimethylsilane Base-1-butene-3-yne, 1.5Kg of formaldehyde and 25Kg of methanol are mixed, add the initiator system (0.03Kg of ammonium sulfate is adsorbed on 0.09Kg of graphite), at a pressure of 0.85MPa, a temperature of 100 The reaction was carried out at ℃ for 45 minutes, and after the reaction was completed, the temperature was lowered to normal temperature, and the volatile substances were removed to obtain the polymer compound described in formula (I).

[0039] Preparation of polymer drag reducer: under the condition of nitrogen protection, the polymer compound described in the formula (I) of 1Kg, the α-octene of 10Kg, the triisobutylaluminum of 0.2Kg and the methyl silicone oil of 8Kg are stirred Mix and lower the temperature to 0° C.; then add 0.5 Kg of titanium trichloride and carry out polymerization reaction at 0° C. for 4 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com