Polyglycolic acid-based biodegradable random copolymer and preparation method thereof

A random copolymer, biodegradable technology, applied in the field of biodegradable materials, can solve the problems of poor thermal stability, ineffective thermal stability and toughening modification, large amount of comonomer, etc., and achieve high crystallinity , excellent biodegradability, and low comonomer content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

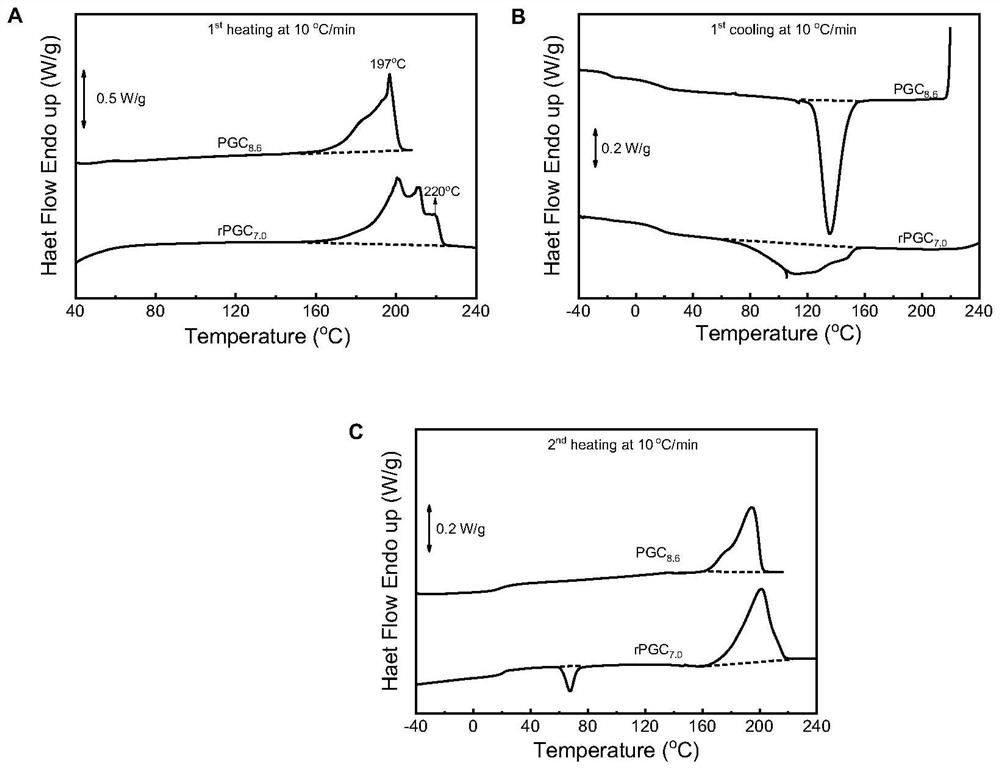

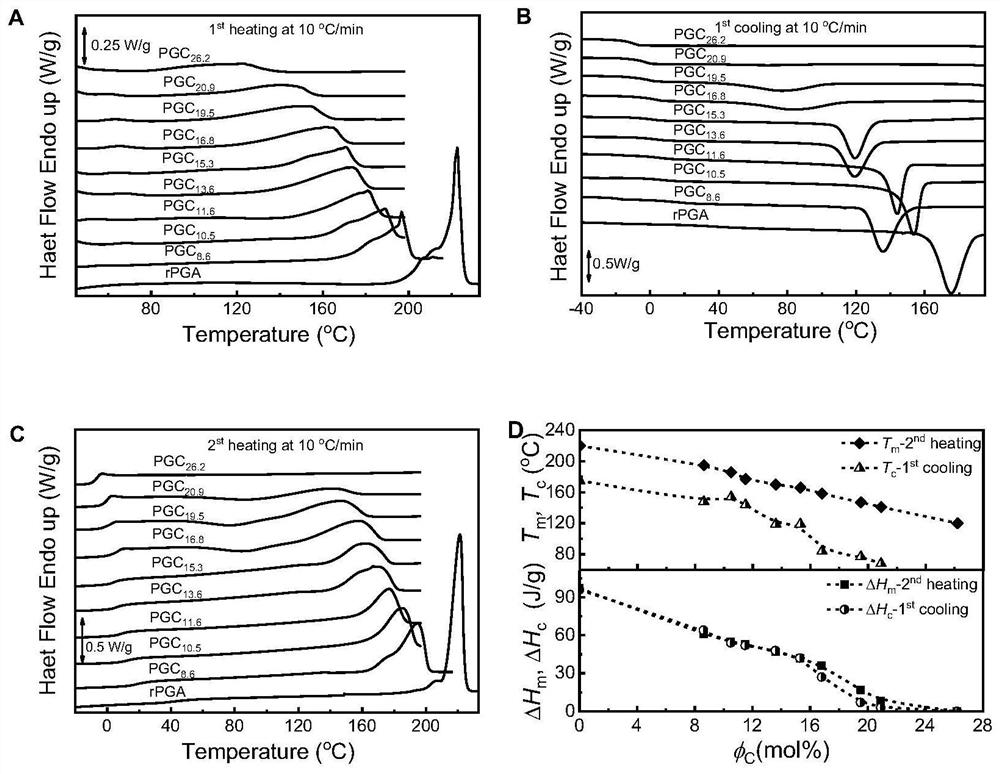

[0079] Embodiment 1 polycondensation method PGC 8.6 —Single melt crystallization peak, narrow crystallization temperature range

[0080] (1) Add 166g of glycolic acid, 16g of ε-caprolactone, 0.32g of organotin and 0.32g of camphorsulfonic acid catalyst into a 250mL reaction flask, and hydrolyze in situ under stirring, normal pressure, reaction temperature of 190°C, and reflux temperature of 100°C -Esterification reaction for 9h to obtain the precursor.

[0081] (2) Prepolymerize the precursor obtained in step (1) for 2 hours under stirring, 25kPa reaction pressure, 190°C reaction temperature, and 50°C reflux temperature to obtain an intermediate.

[0082] (3) Add 0.14g antioxidant 1010, 0.07g antioxidant 626 to the intermediate obtained in step (2), and add 0.32g organic tin and 0.32g camphorsulfonic acid catalyst, place stirring, 80Pa reaction pressure, The polycondensation reaction was carried out at a reaction temperature of 200°C and a reflux temperature of 70°C for 5 ho...

Embodiment 2

[0083] Embodiment 2 polycondensation method PGC 26.2 — degree of randomness 1.08

[0084] (1) Add 140 g of glycolic acid, 70 g of ε-caprolactone, and 0.37 g of an organotin catalyst into a 250 mL reaction flask, and perform an in-situ hydrolysis-esterification reaction under stirring, normal pressure, 190° C. reaction temperature, and 100° C. reflux temperature for 6 h, get the precursor.

[0085] (2) Prepolymerize the precursor obtained in step (1) for 3 hours under stirring, 50 kPa reaction pressure, 190° C. reaction temperature, and 65° C. reflux temperature to obtain an intermediate.

[0086] (3) Add 0.17g antioxidant 1010, 0.085g antioxidant 626 to the intermediate obtained in step (2), and add 0.37g organotin catalyst, place stirring, 23Pa reaction pressure, 200 ℃ reaction temperature, 65 Under the reflux temperature of ℃, the polycondensation reaction was carried out for 8 hours, and the high-performance biodegradable random copolymer based on glycolic acid was obtain...

Embodiment 3

[0087] Embodiment 3 polycondensation method PGC 10.5 — High performance product 1

[0088] (1) Add 160g of glycolic acid, 21g of ε-caprolactone, 0.32g of organotin and 0.32g of camphorsulfonic acid catalyst into a 250mL reaction flask, and hydrolyze in situ under stirring, normal pressure, reaction temperature of 170°C, and reflux temperature of 100°C -Esterification reaction 10h, obtain precursor.

[0089] (2) Prepolymerize the precursor obtained in step (1) for 2 hours under stirring, 25kPa reaction pressure, 190°C reaction temperature, and 50°C reflux temperature to obtain an intermediate.

[0090] (3) Add 0.14g antioxidant 1010, 0.07g antioxidant 626 to the intermediate obtained in step (2), and add 0.32g organic tin and 0.32g camphorsulfonic acid catalyst, place stirring, 80Pa reaction pressure, The polycondensation reaction was carried out at a reaction temperature of 200°C and a reflux temperature of 76°C for 6 hours to obtain the high-performance biodegradable random...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com