Large-size wafer level nano-patterned sapphire substrate imprinting device and method

A technology of sapphire substrate and nano-pattern, which is applied in the direction of photolithographic process exposure device, photographic process of patterned surface, instruments, etc., which can solve the problems of high interface dislocation density, low replication accuracy, and replicated pattern defects, etc. , to achieve the effects of uniform distribution of imprinting force, simplified equipment structure and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings and the embodiments given by the inventor according to the technical solution of the present invention.

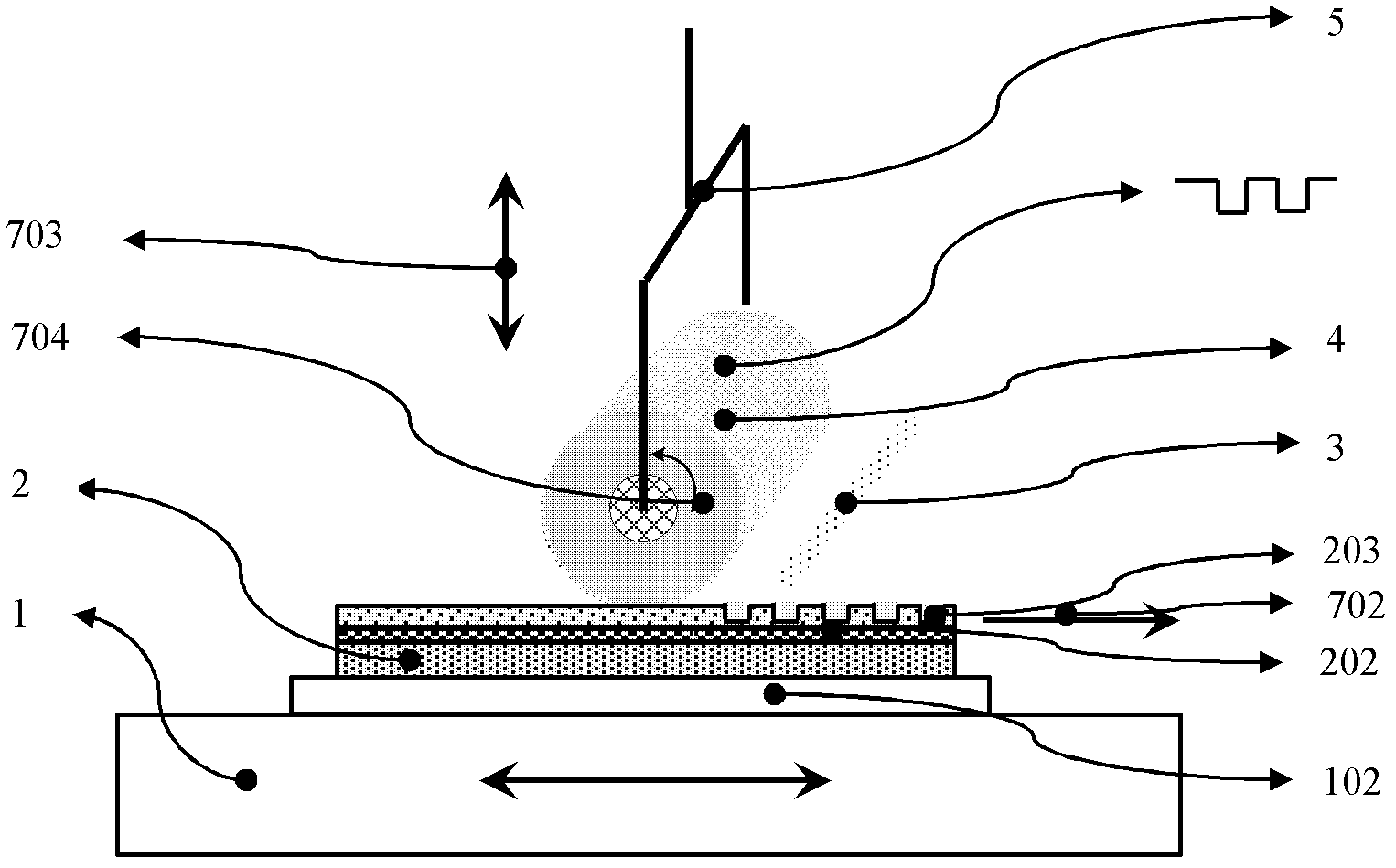

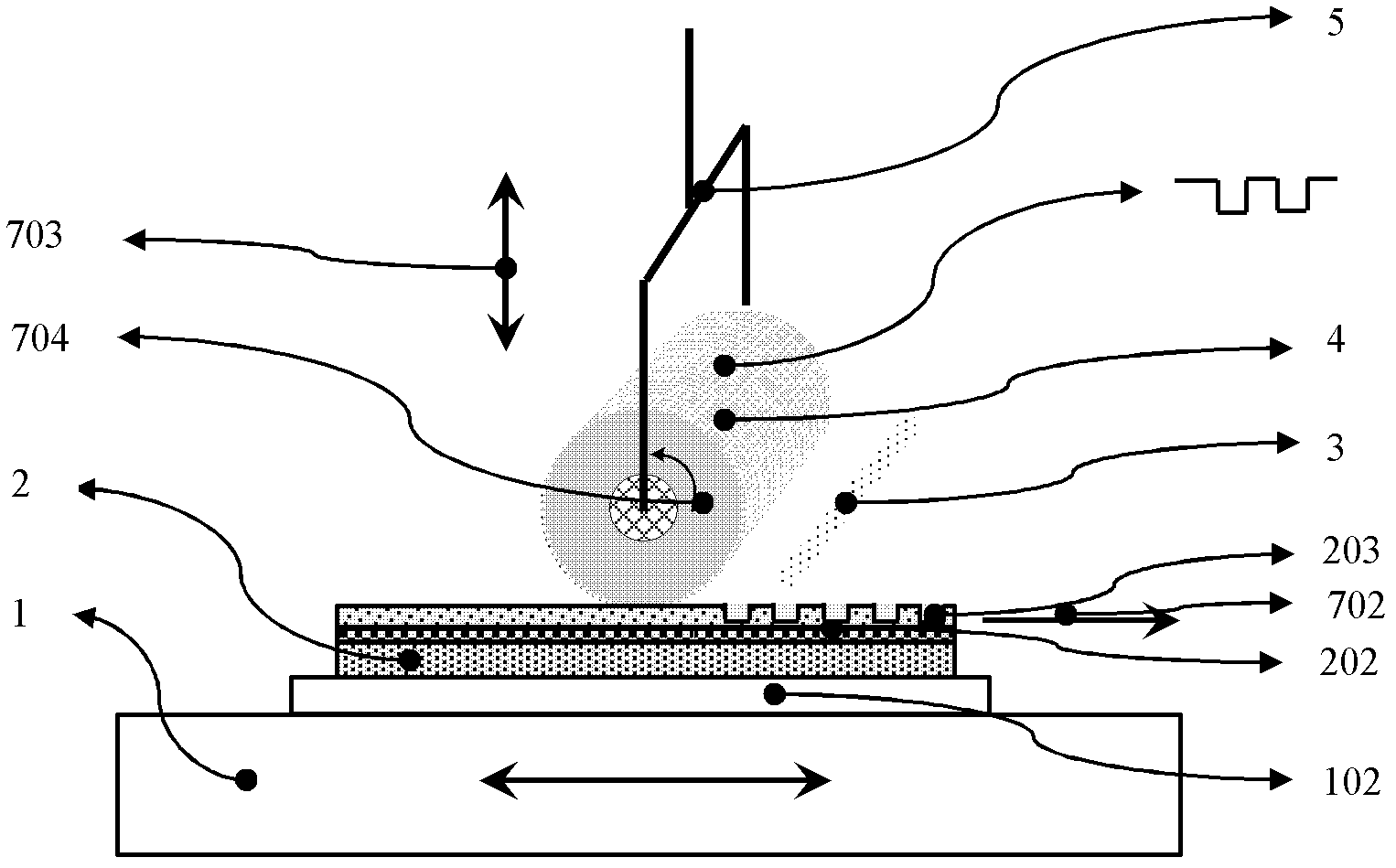

[0052] figure 1 , figure 2 In the present invention, a 4-inch (about 100 mm) nano-patterned sapphire substrate 2 is taken as an example to describe in detail the manufacturing device and method for realizing wafer-level nano-patterned sapphire substrates using the roll-to-plane nanoimprint process.

[0053] A large-scale wafer-level nano-patterned sapphire substrate imprinting device, which includes: a workbench 1 that carries a sapphire substrate 2 and moves in the x-y direction, and is provided with a resist 203 on the workbench 1 The sapphire substrate 2, above the sapphire substrate 2, is provided with a roller-type imprinting mold 4 for longitudinal imprinting along the z-axis 703, and the roller-type imprinting mold 4 is connected to the imprinting m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com