Glue laminated wood member with controllable dimensional stability and preparation method thereof

A technology of dimensional stability and glulam, applied in the jointing of wooden veneers, chemical instruments and methods, manufacturing tools, etc., can solve problems such as poor durability, reduced strength, uncontrollable component quality, etc., and achieve low price and variation The effects of reduced durability, extended service life and service safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

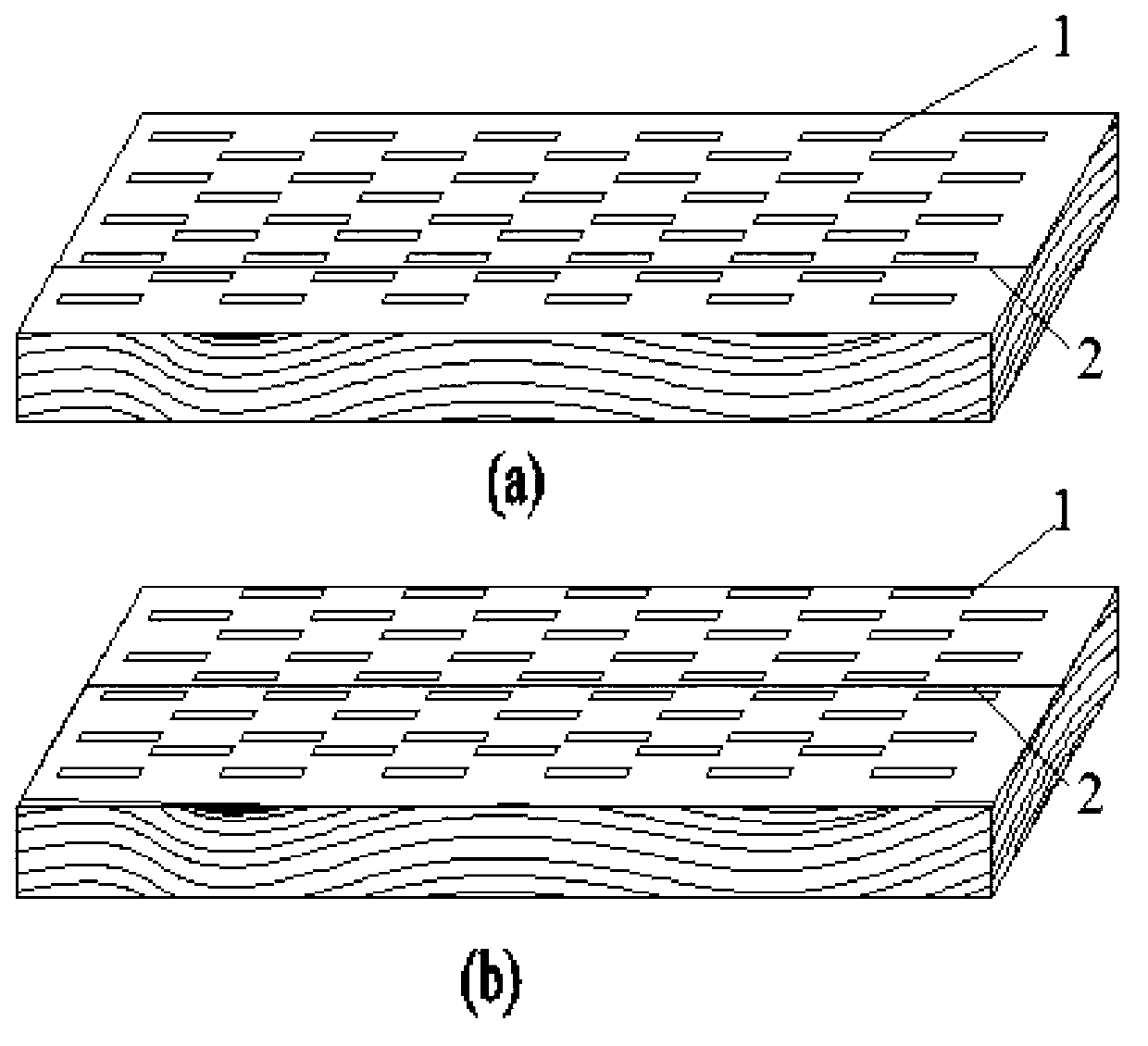

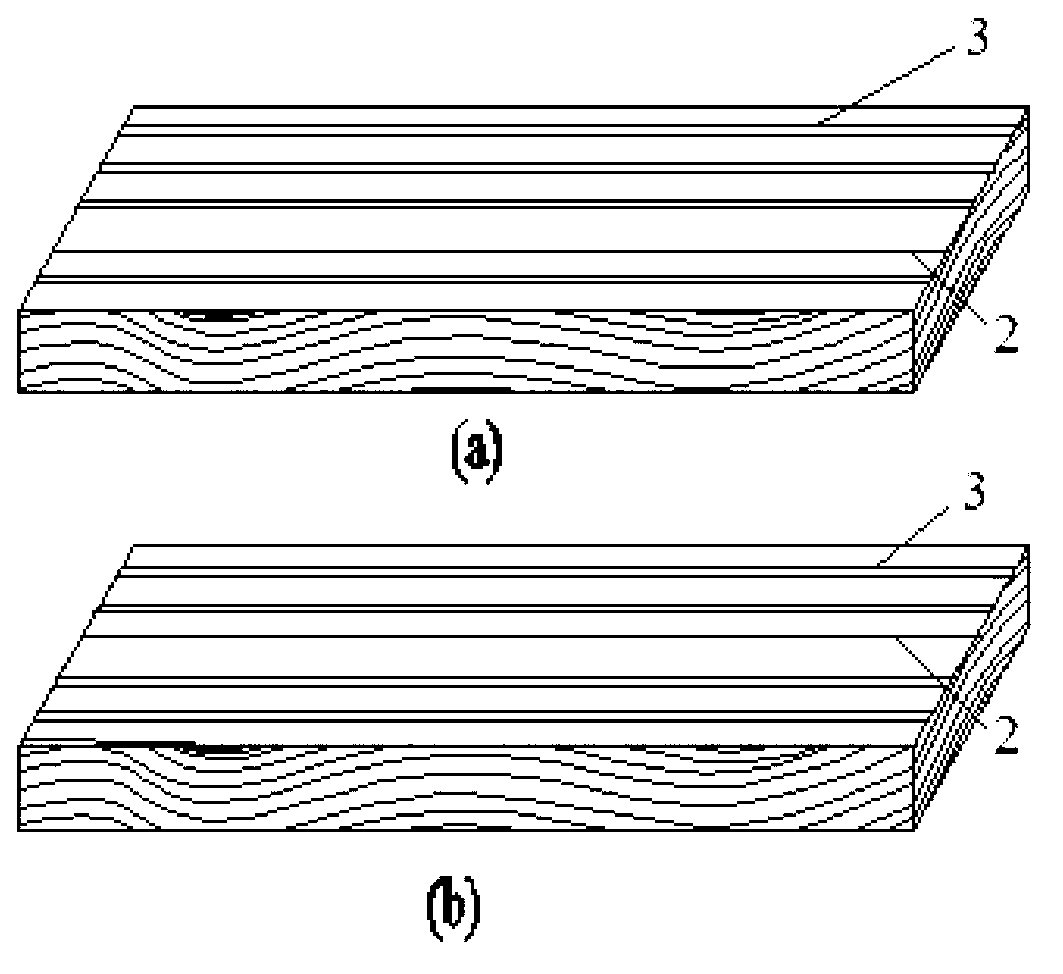

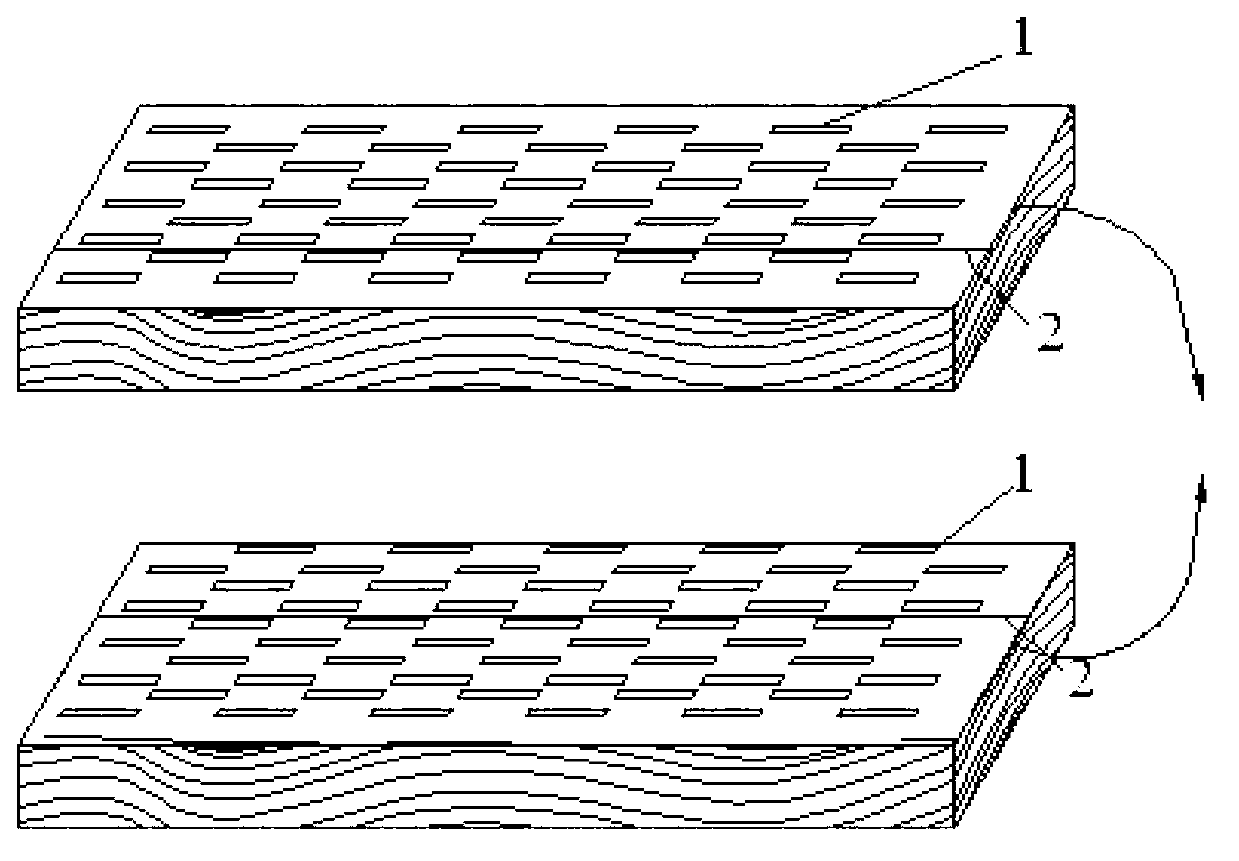

[0042] like figure 1 , 3 As shown in and 5, a glulam component with controllable dimensional stability is prepared, which is composed of laminates and adhesive layers under pressure and lamination. , the indentation laminate has intermittent indentations 1 set along the grain direction, the indentation is staggered in the length and width directions of the laminate, and the adhesive layer between the adjacent indentation laminates is the adhesive layer that bonds the surface of the indentation laminate, The indentation is filled with adhesive. There is a laminate with intermittent indentations, and each row and column of indentations are staggered in the length and width directions of the laminate.

[0043] The glulam component is made of structural wood or artificial fast-growing wood through finger joint length, horizontal splicing and thickness stacking in turn. The preparation steps are: (1) Log wood: through mechanical sawing and other processing methods, the The fast...

Embodiment 2

[0052] (1) Logs: Through mechanical sawing and other processing methods, the fast-growing eucalyptus logs are made into specifications with a thickness of 45mm, a width of 200mm and a length of 3000mm. According to the structural design requirements, the inherent decay, knots, Defects such as twill and cracks are eliminated and controlled;

[0053] (2) Indentation: plan the large surface of the standard sawn timber, and process intermittent indentation along the grain direction by mechanical external force. The indentation width is 4mm, and the indentation depth is 1 / 3 of the thickness of the standard timber. The length is 15mm, the clear distance of each row of indentations along the grain direction is 20mm, the clear distance of each row of indentations in the width direction of the laminate is 25mm, and each row of indentations on the same laminate is staggered;

[0054] (3) Drying: By drying, the moisture content of the control laminate is 18%, and the initial drying time ...

Embodiment 3

[0059] The same as Example 1, the length of a single indentation is 8mm, the clear distance of indentations in each row of indentations along the grain direction is 30mm, the clear distance of each row of indentations in the width direction of the laminate is 10mm, and the indentations of the same laminate are staggered along the board width direction. , Compared with the conventional manufacturing method, the glulam components prepared in this way, the test results show that the flexural strength is increased by more than 5%, the flexural modulus of elasticity is increased by more than 10%, and other mechanical properties are not significantly changed. The dry bond strength between boards does not change significantly, and the wet bond strength between laminates increases by more than 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com