Unsaturated polyester-bonded and glass fiber-reinforced beam and implementation method thereof

An unsaturated and bonding technology, applied in the direction of joists, girders, trusses, etc., can solve the problems of poor performance of wood composite materials, and achieve the effect of good bonding effect, simple production process and high reinforcement strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

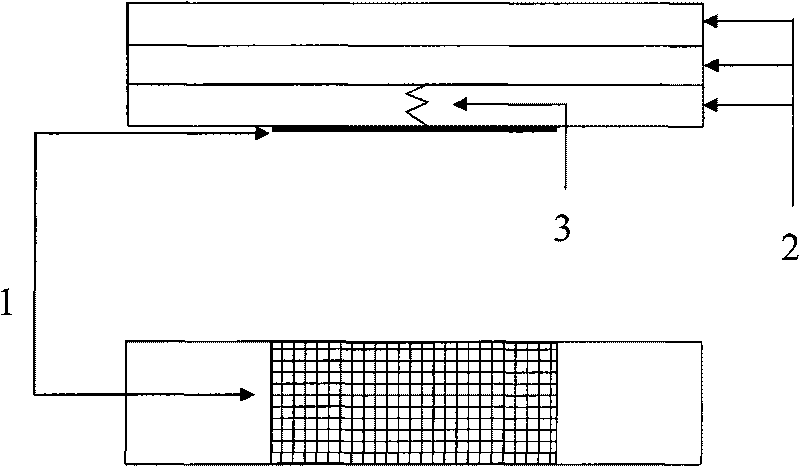

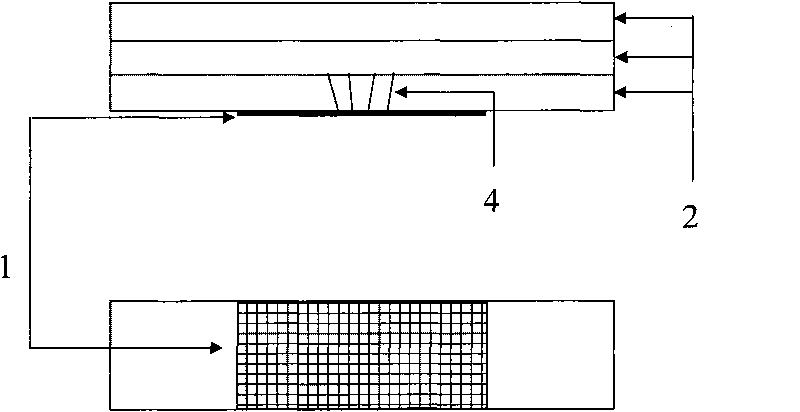

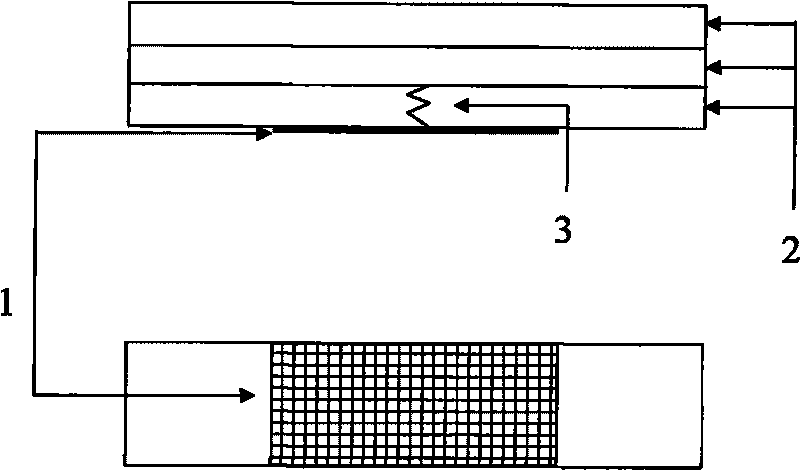

[0015] Let’s illustrate with an example in conjunction with the accompanying drawings:

[0016] After the log is sawn into sawn timber, the target moisture content of drying is 12%, and the moisture content after drying can be 8-12%. Afterwards, the sawn timber is finished, and the finger joints are milled out. The length of the finger joints is 10, or 12, or 15, or 20, or 25, or 30, or 35mm. Apply latex glue to one side of the processed wood laminate 2 ends, the glue amount is: 100, or 200, or 300, or 400, or 500, or 600, or 700g / m 2 . Appropriate pressure is applied longitudinally to the finger joint 3, the end pressure is 4, or 5, or 6, or 7, or 8MPa, and the end pressure time is 1, or 2, or 3, or 4, or 5, or 6, Or 7, or 8s. After the end pressure is completed, keep in good health for more than 24 hours. Apply isocyanate glue to one side of the processed wood laminate 2, and the glue amount is: 100, or 200, or 300, or 400, or 500, or 600, or 700g / m 2 . Carry out blank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com