Method for operating an automated sample workshop

A workshop and sample technology, applied in the direction of chemical instruments and methods, laboratory containers, laboratory analysis data, etc., can solve the problem of insufficient determination of processing steps, inflexibility of the workshop and inability to analyze tests, and sufficient pretreatment of biological sample and other issues to achieve the effect of avoiding delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

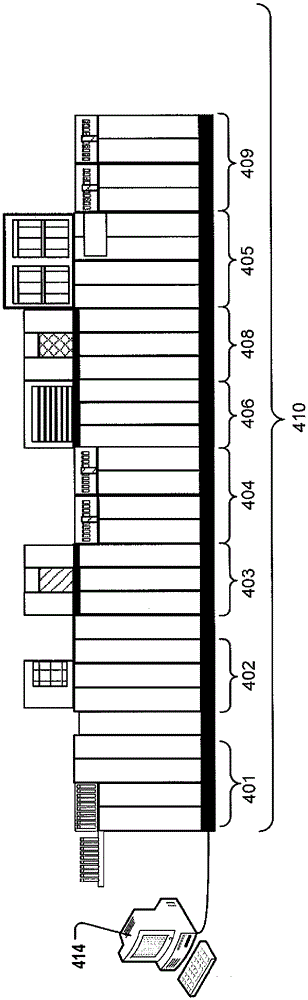

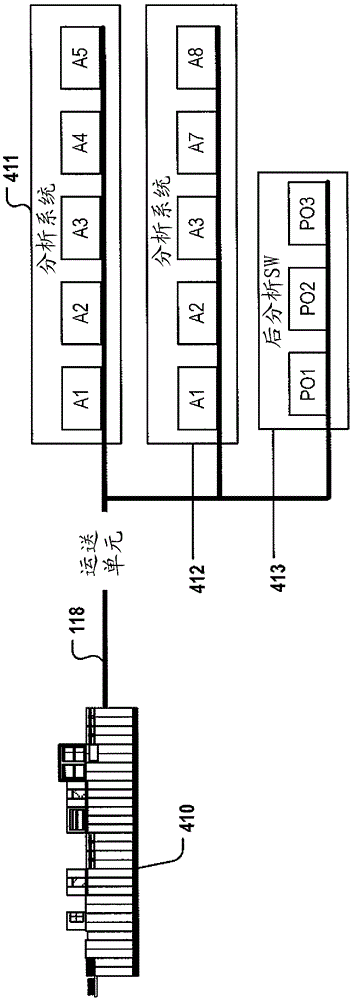

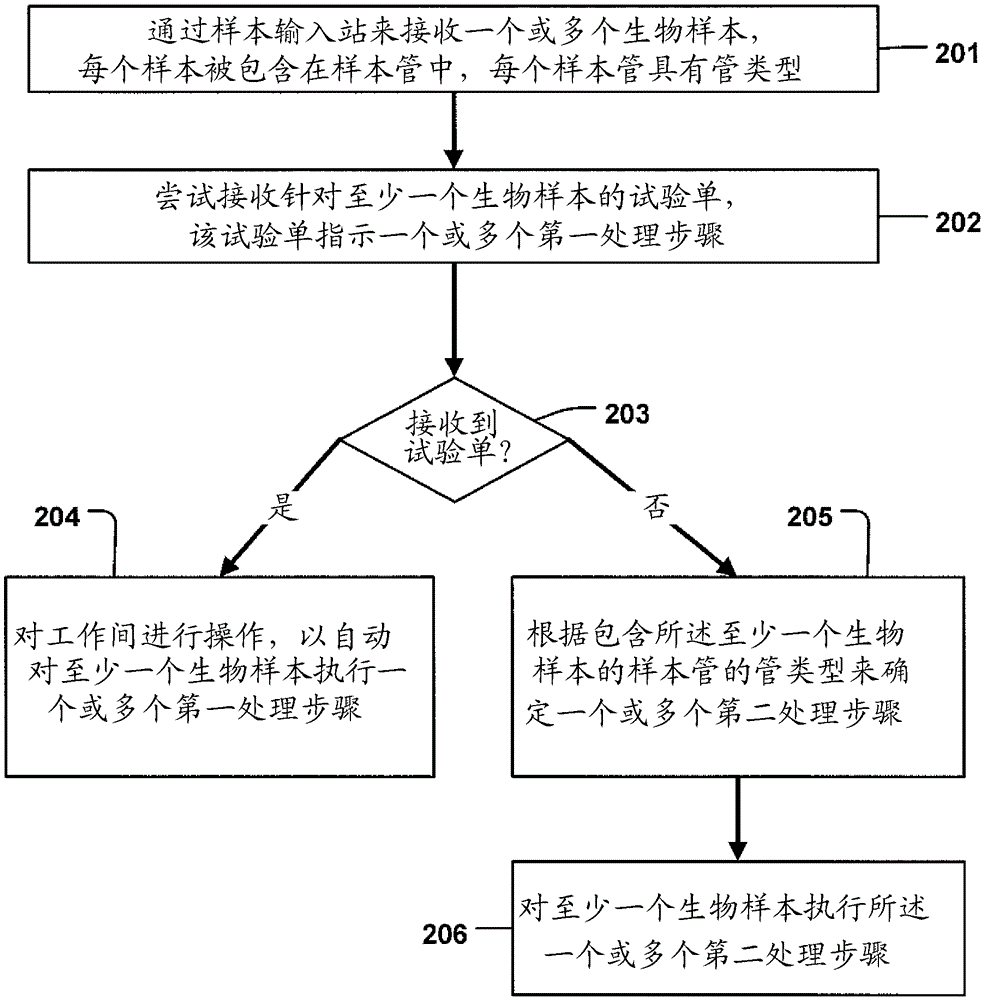

[0118] figure 1 is a block diagram of a sample workspace 102 according to one embodiment of the invention. The automated sample workcell 102 comprises: a sample input station 108; at least one centrifuge 116, 117; a transport unit 118 in the form of a sample conveyor for automatically transporting the biological samples 125 to 130 from the sample input station 108 to the centrifuge 116, 117 or any of the other sample processing units 119 to 121 (eg, aliquoting station 119 or decapping / recapping station 121). The transport unit can also transport the biological sample to the sample buffer station 120, or unload the sample from the buffer station. According to the depicted embodiment, the transport unit is operable to forward at least one received biological sample to one or more analysis systems 134, 131 after one or more pre-analytical processing steps have been performed on said sample and also to Forward to post-analysis sample workshop 132.

[0119] Each sample is tagge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com