Method and system for optimizing the layout of a robot work cell

A work cell, robot technology, applied in general control systems, control/regulation systems, instruments, etc., to solve problems such as finding workstations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

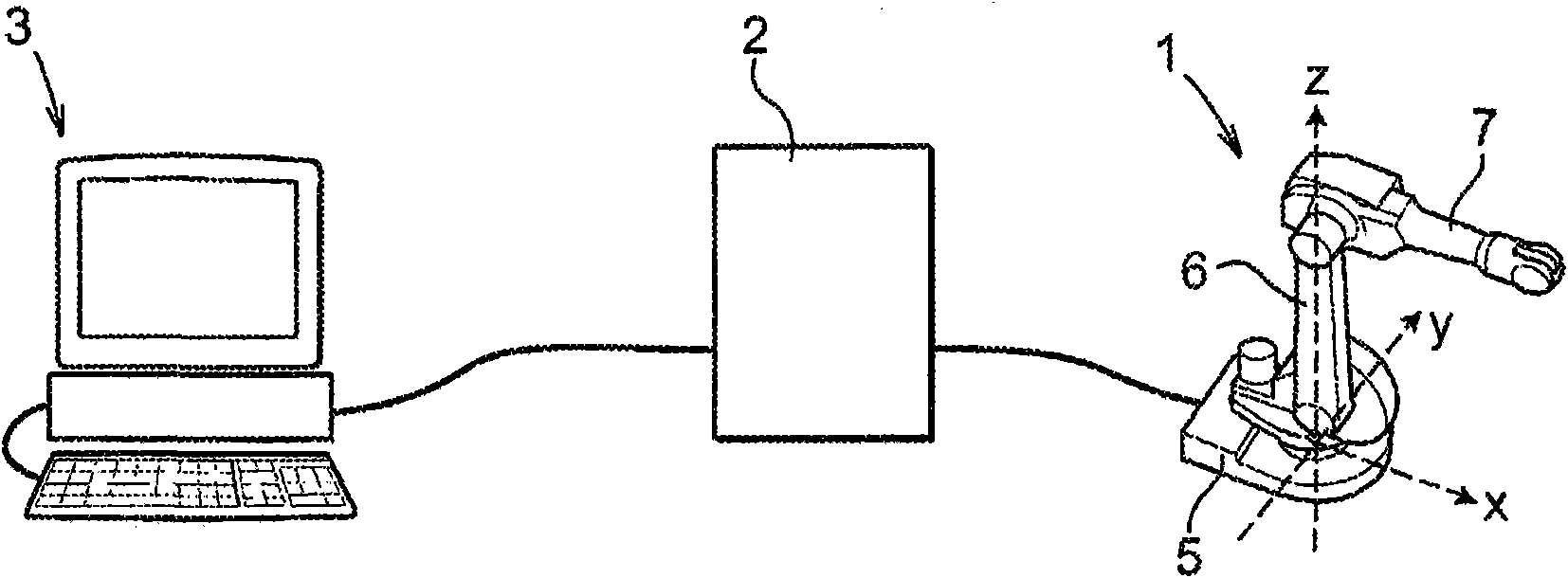

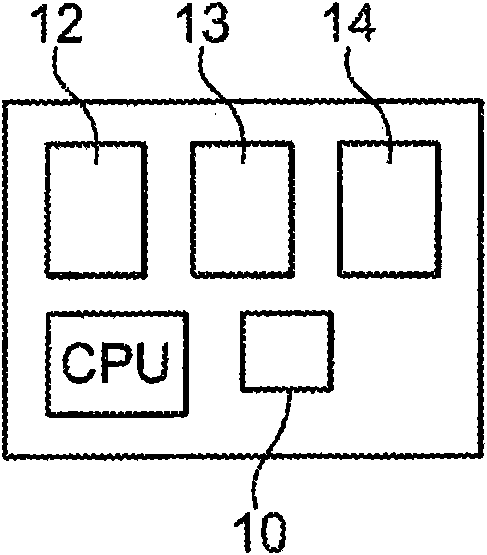

[0047] Figure 1a A robot system is shown comprising a robot 1 , a robot controller 2 and an external computer 3 configured to communicate with the robot controller. The robot includes a plurality of robot parts movable relative to each other. The robot parts are in this case the base 5 and the robot arms 6 , 7 . The base 5 of the robot is arranged in a fixed position relative to the ground. A base coordinate system X, Y, Z is defined relative to the base of the robot. The robot is rotatable with respect to the base in a Z-direction of a base coordinate system of the robot. The robot controller is configured to control movement of the robot according to a control program including instructions for moving the robot along a path to complete a series of tasks on a plurality of workstations. The external computer includes a processor such as a central processing unit (CPU), a memory for storing programs and data, a user input device such as a keyboard and a mouse, a communicati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com