A welding production line for an automobile body side wall outer panel assembly

A technology for side panels and car bodies, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problem of weak, fully automated car body side panel assembly, and multi-station parallelism, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Attached below Figures 1 to 16 And the embodiment describes the present invention in detail.

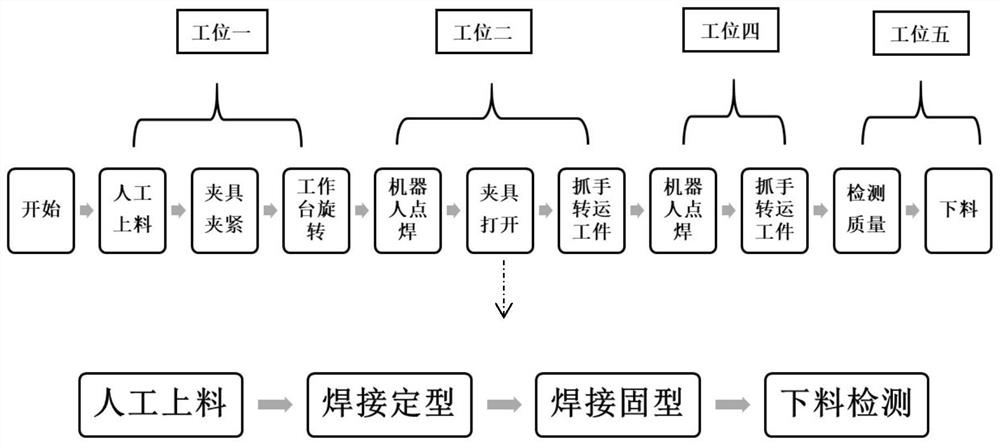

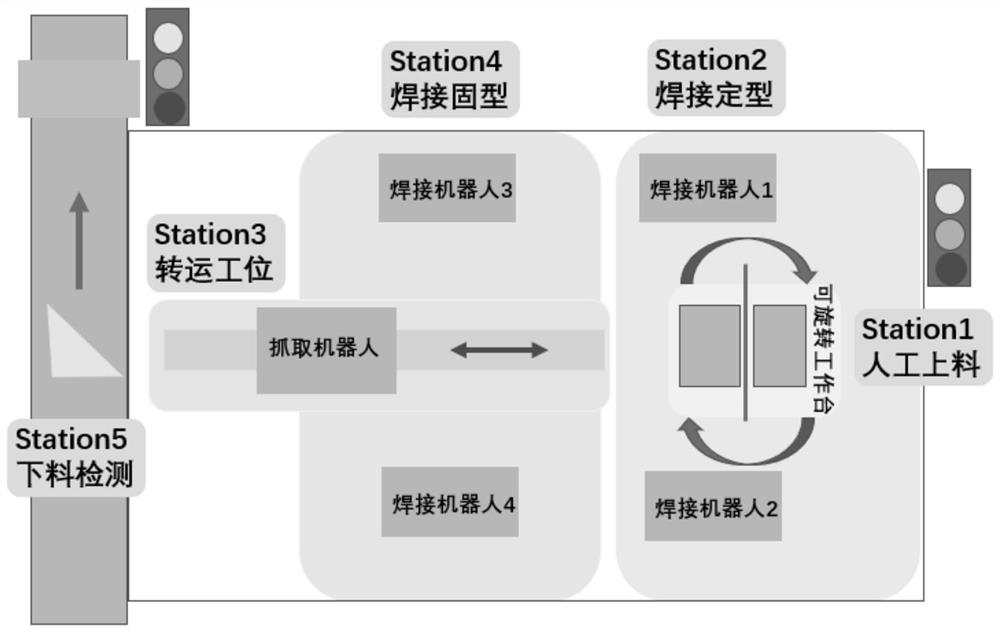

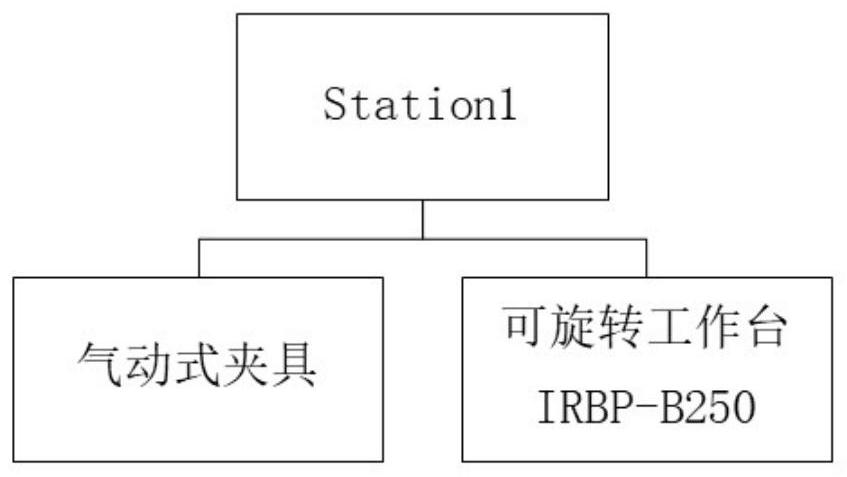

[0050] Such as figure 1 As shown, based on the analysis of the system workflow and the design of the assembly line, the welding production line is equipped with five stations to complete the processes of manual loading, welding setting, transfer, welding solidification and unloading inspection. The state of the product before entering the welding line is: four parts of H-pillar, B-pillar, sill plate and A-pillar. First, the loading is completed at the loading station. After the loading is in place, the rotatable table rotates, and the workpiece enters the welding and shaping station, and at the same time, the next workpiece starts to be loaded. The welding shaping manipulator welds the key welding points of the assembly. In this station, the workpiece is welded into a single piece. After the welding is completed, the transfer station manipulator moves to transfer the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com