Environment-friendly garbage incineration process and matched device

A garbage incineration and garbage technology, which is applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of complex garbage composition, no market application value of rotary combustion technology, and short contact time, so as to solve the problem of secondary pollution and guarantee The effect of long-term smooth operation and stable calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

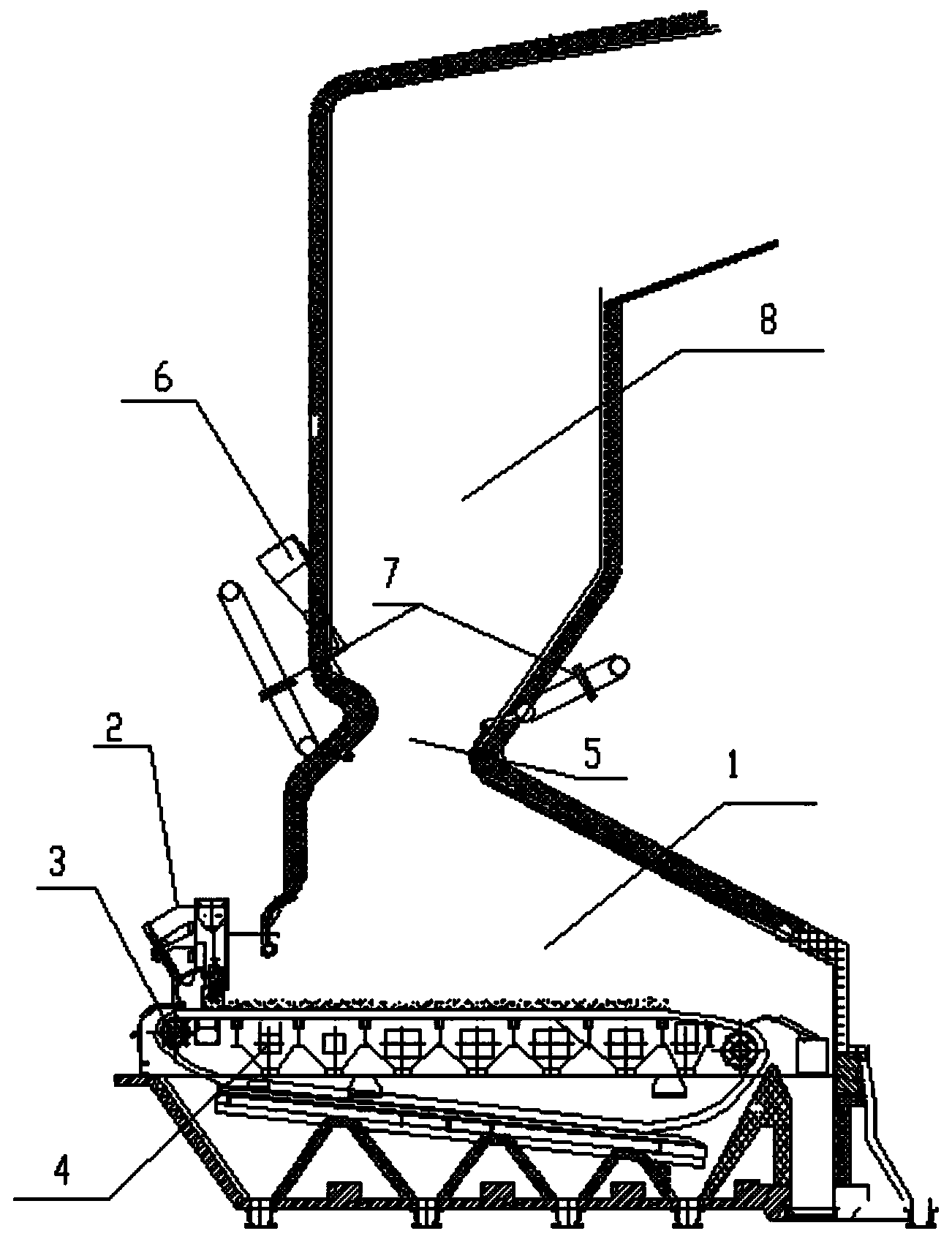

Image

Examples

Embodiment Construction

[0018] The following embodiments further illustrate the technical solutions of the present invention, but are not intended to limit the protection scope of the present invention.

[0019] A waste incineration treatment method, which aims to add biomass fuel during the waste incineration process, and use the large amount of heat generated by the biomass fuel combustion to preheat the newly entered waste and decompose the toxic substances produced during the waste incineration process.

[0020] The specific operation method can make the block biomass fuel burn in the lower part of the furnace, and the garbage to be incinerated and the powder biomass fuel are fed from the top of the furnace, and the powder biomass fuel in the falling process and the block biomass fuel on the grate are decomposed during the combustion process. The combustible flue gas produced meets, and at the same time, mixes with the secondary air of the boiler to generate high-temperature flue gas, which prehea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com