Oxygen spraying smelting reduction iron-making process

A process and technology of molten iron, which is applied in high-temperature smelting reduction smelting and smelting reduction ironmaking. It can solve problems affecting the rhythm of smelting, simple structure, and easy burning loss, etc., so as to improve heat exchange efficiency, increase service life, and increase injection depth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

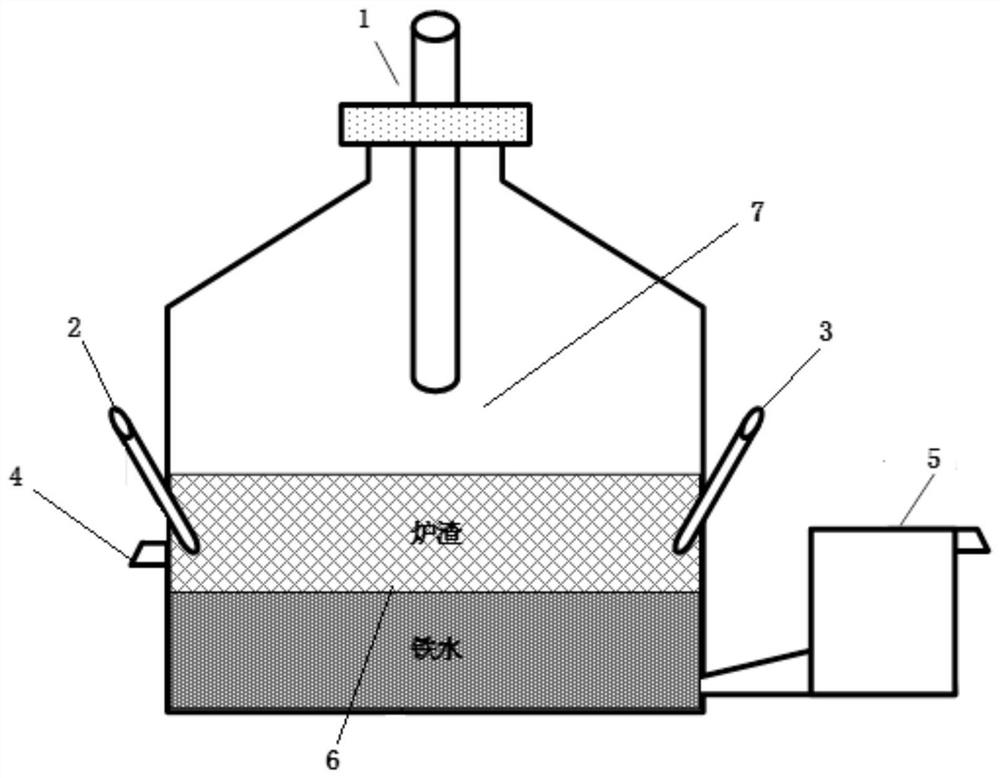

[0040] An oxygen injection smelting reduction ironmaking process, comprising the following steps,

[0041] When selecting ore raw materials, strictly control the phosphorus content in the ore 53%, strictly control the particle size of the ore powder 2 O3+SiO 2 ).

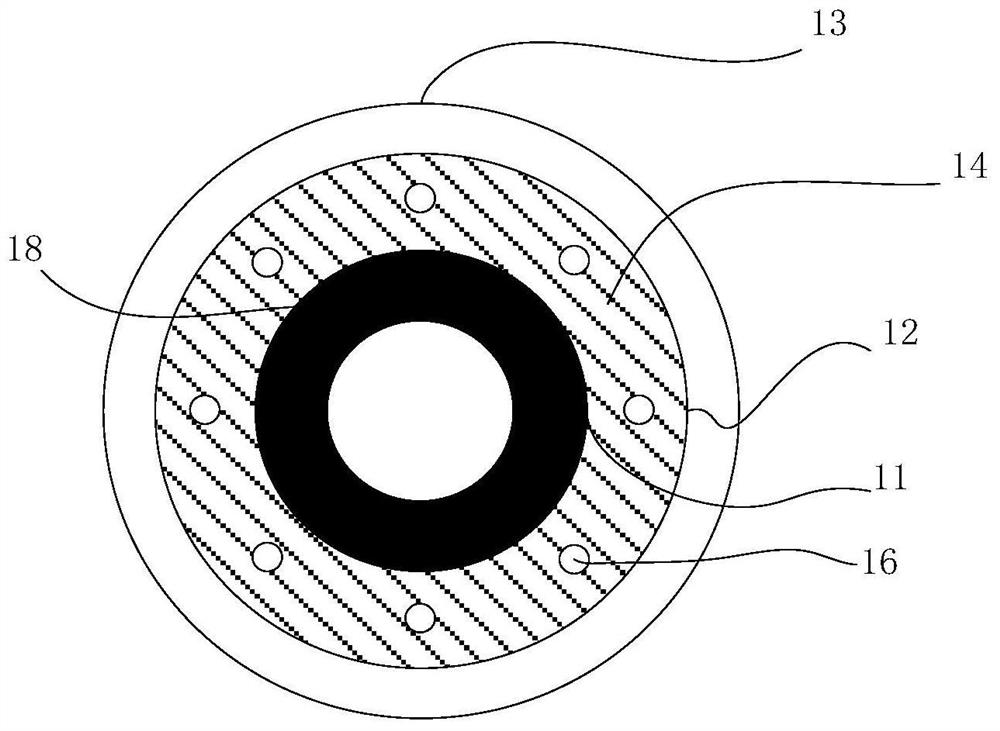

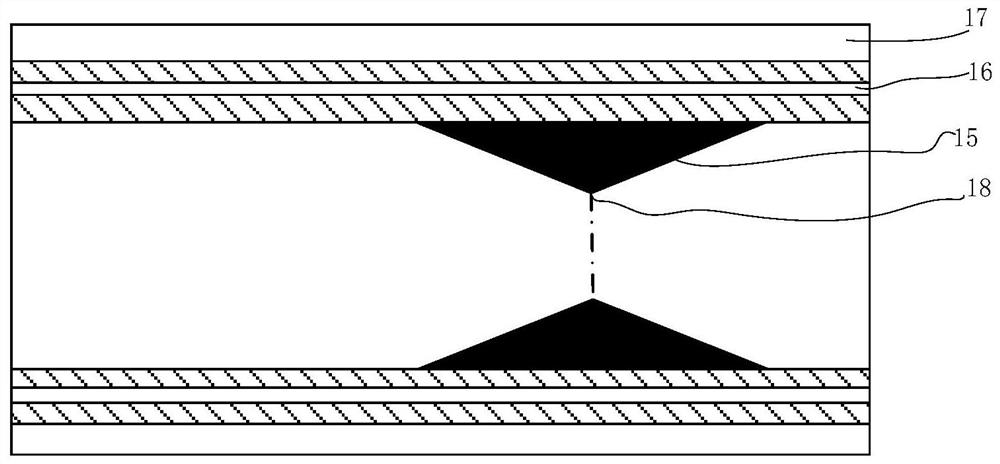

[0042] At the same time, ensure that the particle size of coal powder is less than 6mm, the moisture content of coal powder is less than 3%, and the temperature is ≥80°C. Inert or reducing gas is sprayed into the reduction zone (6) of the smelting reduction reaction furnace through the coal powder spray gun (3) respectively, and passes through the slag layer. Spray into the molten iron pool to replenish carbon for the molten iron, the temperature of the molten pool is controlled within the range of 1450-1550°C, and the gas carrying capacity of the pulverized coal injection system is 1500-4000Nm 3 / h, hot ore blowing gas consumption 7000 ~ 10000Nm 3 / h, to ensure that the injection system is stable, so that the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com