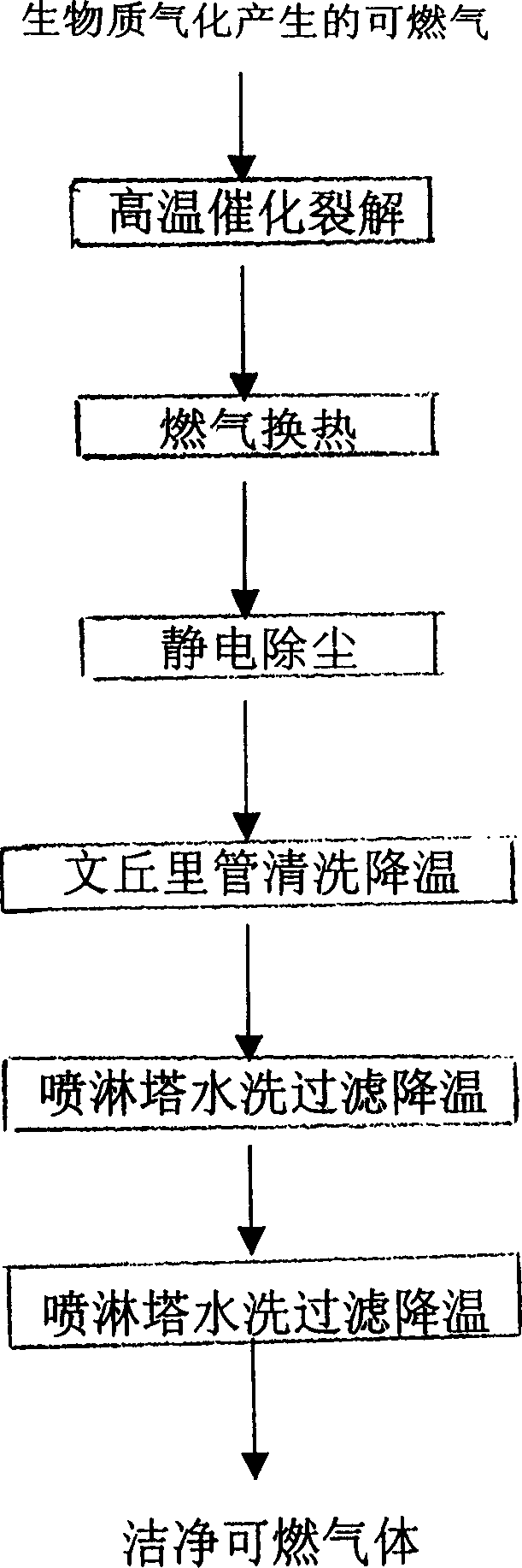

Cracking purification method for combustible gas produced by gasifying crude material

A biomass and gas technology, which is applied in the direction of catalytic treatment of combustible gas, can solve the problems of easy carbon deposition and deactivation of catalysts, increased gas production costs, and incomplete purification, and achieves increased market application potential, obvious environmental protection benefits, and production strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

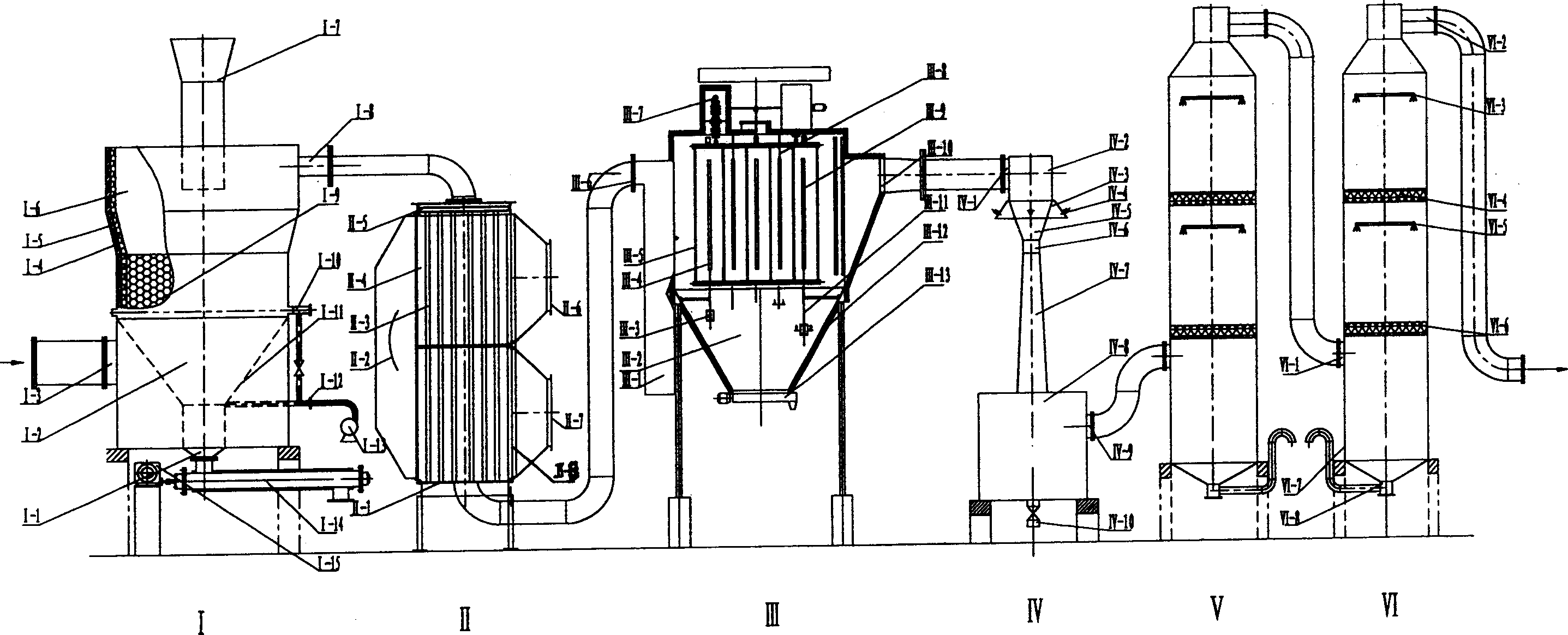

[0031] This embodiment is a 3MW circulating fluidized bed biomass gasification power station, which uses the gas cracking and purification method and combined device of the present invention to crack the combustible gas containing tar and dust produced by the gasification of the circulating fluidized bed biomass gasification furnace Purification, clean combustible gas after purification is supplied to 6 500KW gas generator sets for power generation.

[0032] Example uses figure 2 The combustible gas pyrolysis and purification combination device produced by biomass gasification is shown, which includes moving bed cracker I, heat exchanger (air preheater (cooler) II), electrostatic precipitator III, Venturi tube IV and water washing spray tower V and VI; the gas outlet of the former device of the six independent devices is connected with the gas inlet of the latter device with pipelines to form a complete combined device.

[0033] The moving bed cracker I is a fixed bed gasifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com