Two-stage cement kiln multi-source solid waste coupling pyrolysis gasification method and device and application thereof

A cement kiln, two-stage technology, applied in the field of two-stage cement kiln multi-source solid waste coupled pyrolysis gasification, can solve the problems of single type, difficulty in rational utilization, cement clinker composition and temperature fluctuation, etc., to achieve The effect of improving the quality of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

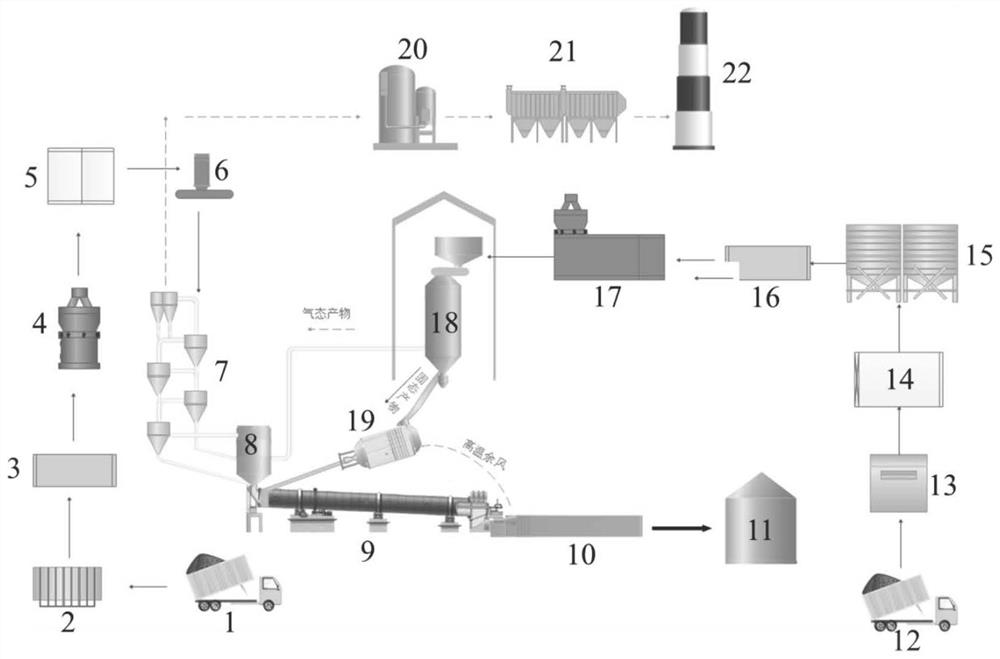

[0069] Such as figure 1 As shown, it is a device for realizing a two-stage cement kiln multi-source solid waste coupling pyrolysis gasification method disclosed in this embodiment, an inorganic solid waste storage bin 15 and an inorganic solid waste storage bin 2, and an inorganic solid waste transport vehicle 1 , Inorganic solid waste storage bin 2, batching metering room 3, raw material mill 4, raw meal homogenization storehouse 5, feeding metering room 6 and preheater 7, rotary kiln 9, grate cooler 10, clinker bin 11 are sequentially connected , the organic solid waste transport vehicle 12, pulverizer 13, organic solid waste pretreatment system 14, organic solid waste storage bin 15, raw material batching metering room 16, pulverizer 17, gasifier 18, supersonic high-temperature airflow The mill 18 and the rotary kiln 9 are connected sequentially. The gasifier 18 is a double-layer gasifier. The bottom of the gasifier 18 is provided with at least two outlets. The jet mill 19...

Embodiment 2

[0073] Using the device described in Example 1 to carry out a two-stage cement kiln multi-source solid waste coupling pyrolysis gasification method, including:

[0074] Taking oily sludge and municipal sludge as examples to treat organic solid waste, the calorific value of oily sludge is 17.9MJ / kg, and the calorific value of municipal sludge is 10.42MJ / kg. Oily sludge contains a large amount of SiO 2 , Municipal sludge has been flocculated with iron salts, and has a large amount of iron elements that are beneficial to cement production. After drying and crushing, the two are mixed and granulated in a granulator at a ratio of 71.5:28.5, and the particle size is 30mm to 50mm. , the calorific value is above 3000kcal.

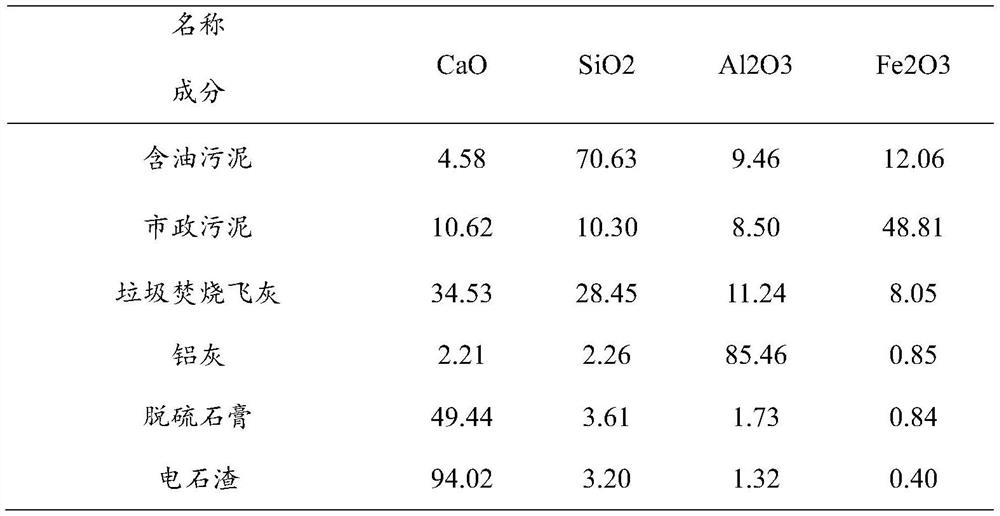

[0075] Waste incineration fly ash, aluminum ash, desulfurized gypsum and calcium carbide slag are used as inorganic solid waste. Waste incineration fly ash is pretreated and dechlorinated by washing with water. The composition of various solid wastes is shown in T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com