Preparation method of large primary crystal alpha-alumina

A technology of alumina and primary crystal, which is applied in the field of preparation of large primary crystal α-alumina, which can solve the problems of unstable performance of α-alumina, downtime and maintenance of kiln equipment, and high maintenance cost, so as to reduce corrosion damage and maintenance The effect of cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing large primary crystal α-alumina, comprising the following steps,

[0029] Step 1: Boric acid and calcium carbonate reagent were mixed at a ratio of 10:1 for 20 minutes to obtain M1. Among them, the purity of boric acid and calcium carbonate is greater than 99%.

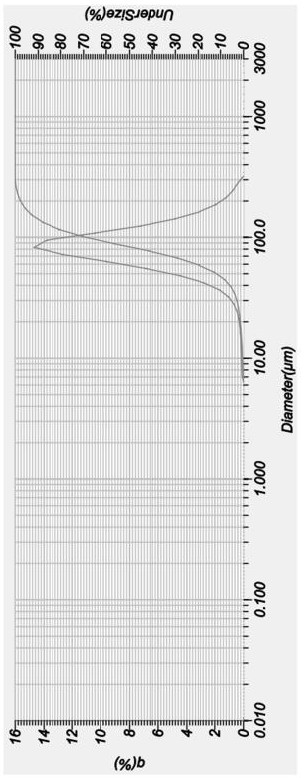

[0030] Step 2: Add 1%wt of M1 to the γ-alumina raw material and mix with a mixer for 120min to obtain M2. Among them, the moisture content of γ-alumina is less than 3%wt, and the median particle size is 50-100 μm.

[0031] Step 3: Put M2 into a high-temperature furnace for calcination at 1500° C. for 5 hours to obtain M3. Among them, before M2 is put into the high-temperature furnace, the temperature in the furnace will be gradually raised to 1000°C, and the heating time is 1.5-2h. During the heating process, nitrogen and air are alternately injected into the furnace, and the time for a single injection of nitrogen or air is 0.5h. , flow 1~10m 3 / min.

[0032] Step 4: Put M3 into the...

Embodiment 2

[0034] A method for preparing large primary crystal α-alumina, comprising the following steps,

[0035] Step 1: Boric acid and calcium carbonate reagent were mixed at a ratio of 10:2 for 20 minutes to obtain M1. Among them, the purity of boric acid and calcium carbonate is greater than 99%.

[0036] Step 2: Add 2%wt of M1 to the γ-alumina raw material and mix with a mixer for 120min to obtain M2. Among them, the moisture content of γ-alumina is less than 3%wt, and the median particle size is 50-100 μm.

[0037] Step 3: Put M2 into a high-temperature furnace for calcination at 1500° C. for 5 hours to obtain M3. Among them, before M2 is put into the high-temperature furnace, the temperature in the furnace will be gradually raised to 1000°C, and the heating time is 1.5-2h. During the heating process, nitrogen and air are alternately injected into the furnace, and the time for a single injection of nitrogen or air is 0.5h. , flow 1~10m 3 / min.

[0038] Step 4: Put M3 into the...

Embodiment 3

[0041] A method for preparing large primary crystal α-alumina, comprising the following steps,

[0042] Step 1: boric acid and calcium carbonate reagent were mixed at a ratio of 10:2 for 20 minutes to obtain M1, wherein the purity of boric acid and calcium carbonate was greater than 99%.

[0043] Step 2: Add 2%wt of M1 to the γ-alumina raw material and mix with a mixer for 120min to obtain M2. Among them, the moisture content of γ-alumina is less than 3%wt, and the median particle size is 50-100 μm.

[0044] Step 3: Put M2 into a high-temperature furnace for calcination at 1300° C. for 5 hours to obtain M3.

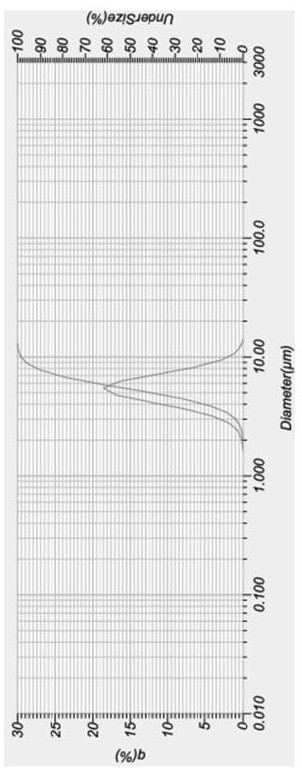

[0045] Step 4: Put M3 into the jet mill to grind, and the classifier cooperates with the classification to select the powder to obtain the product large primary crystal α-alumina, with a median particle size D50 of 4.0 μm. Wherein, the jet mill grinding pressure is 0.50MPa.

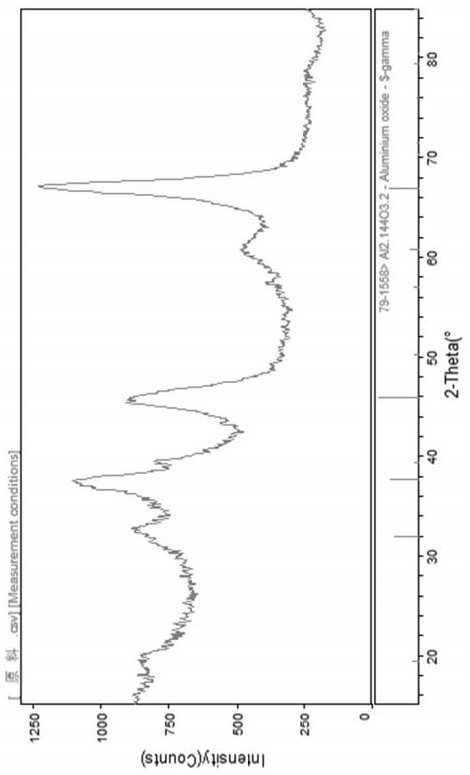

[0046] The γ-alumina raw material before calcination and the large primary crystal α-alumina a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com