Plasma immersion injection structure

A plasma and immersion injection technology, which is applied in the direction of plasma, discharge tube, electrical components, etc., can solve the problems of prolonging the pre-pumping time, corrosion of the inner wall of the chamber, and injection pollution, so as to reduce the introduction of impurity ions, improve efficiency, Reduce the effect of injection contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

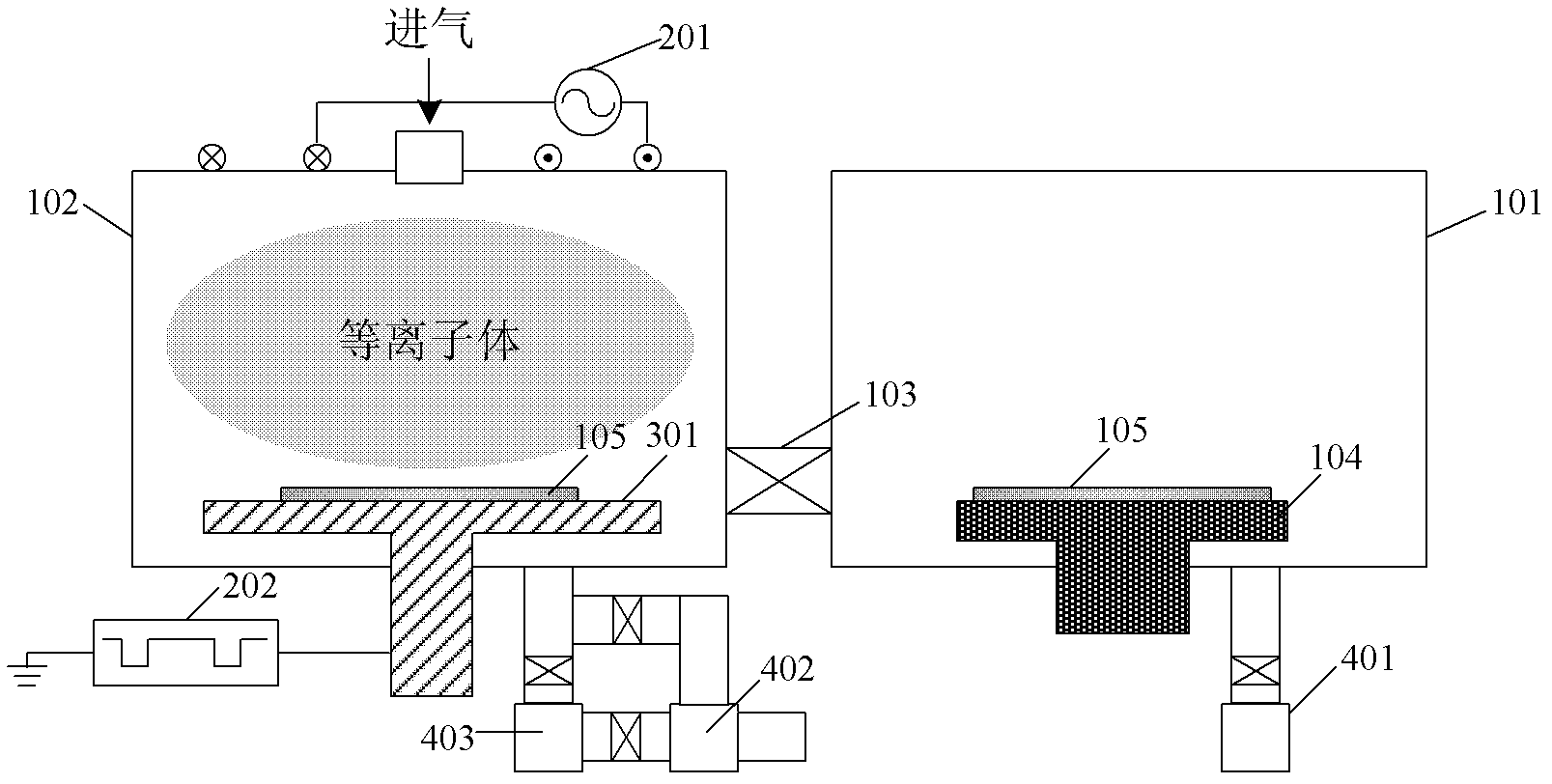

[0020] like figure 1 As shown, this embodiment provides a plasma immersion injection device, including a vacuum chamber, an injection electrode, a power supply part and a vacuum system, wherein the vacuum chamber includes a pre-injection chamber 101 and an injection chamber 102, and the pre-injection chamber The material of 101 and injection chamber 102 is aluminum. A flapper valve 103 is provided between the pre-injection chamber 101 and the injection chamber 102 , and the flapper valve 103 controls the pre-injection chamber 101 to communicate with or separate from the injection chamber 102 . The material of the injection electrode 301 is aluminum, and is disposed in the injection chamber 102 . The power supply part includes a plasma pulsed radio frequency power supply 201 and an injection bias power supply 202. The plasma pulsed radio frequency power supply 201 is used to excite the process gas discharge entering the injection chamber 102 to generate plasma, and the injecti...

Embodiment 2

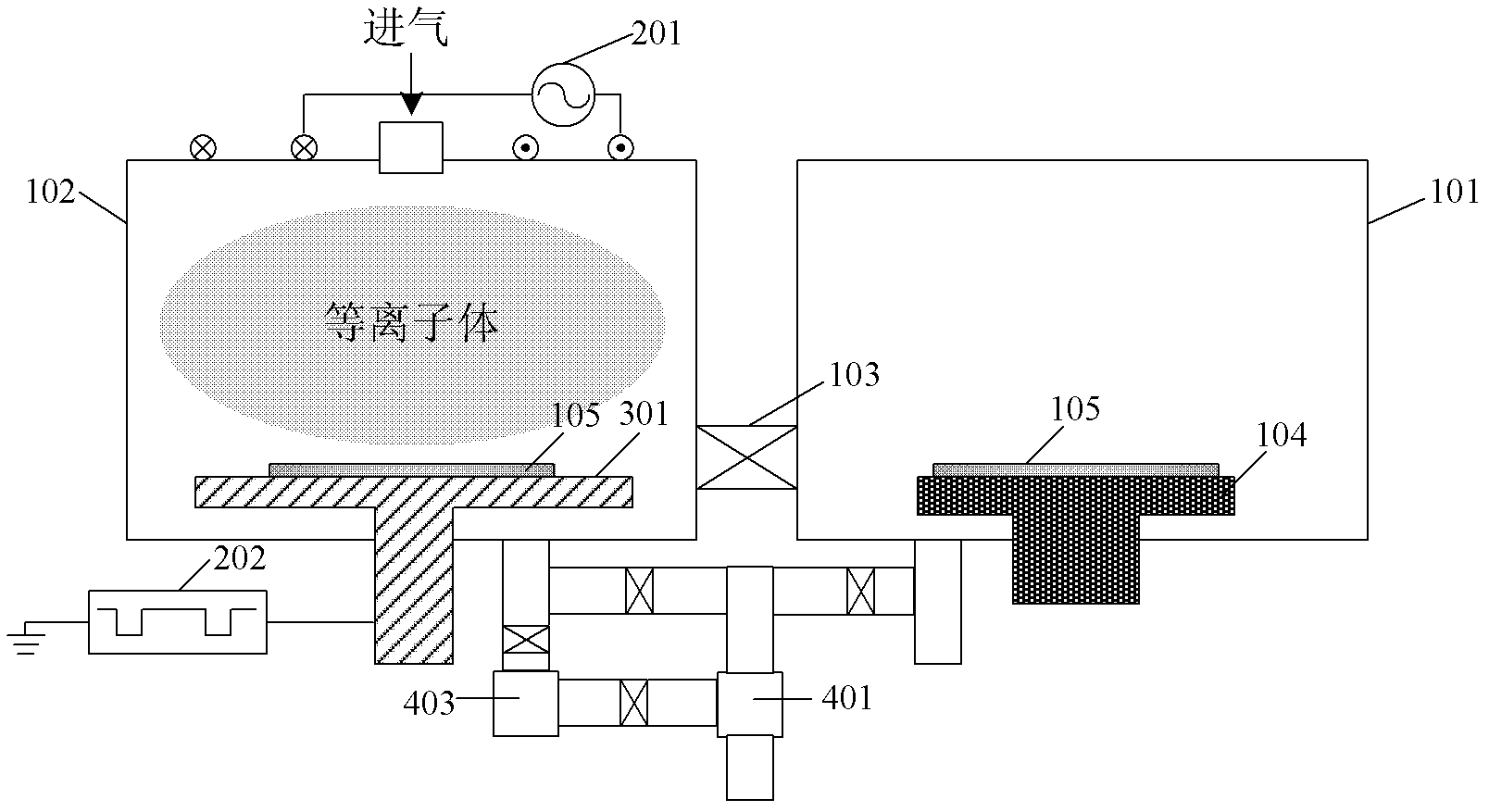

[0026] like figure 2 As shown, this embodiment provides a plasma immersion injection device. In this embodiment, the pre-injection chamber 101 and the injection chamber 102 share a mechanical pump 401, and the connection relationship between other components in this embodiment is the same as the embodiment 1 is the same.

[0027] In this embodiment, when starting the injection, first open the chamber cover of the pre-injection chamber 101, put the substrate 105 to be injected on the robot arm 104, and then close the cover. Under the action of the mechanical pump 401, when the pre-injection chamber is After the vacuum degree in 101 reaches the process requirements, the flapper valve 103 is opened, and the substrate 105 is transported by the robot 104 and placed on the injection electrode 301 of the injection chamber 102; the robot arm 104 returns to the pre-injection chamber 101 and then closes the flapper valve 103; Under the action of the combined pump of the mechanical pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com