Alkaline-process smoke halogen removal device and removal method

A halogen and removal technology, applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of the desulfurization wastewater cannot be recycled, affect the desulfurization effect, increase water consumption, etc., to improve the recycling rate and operation. effect, the effect of reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

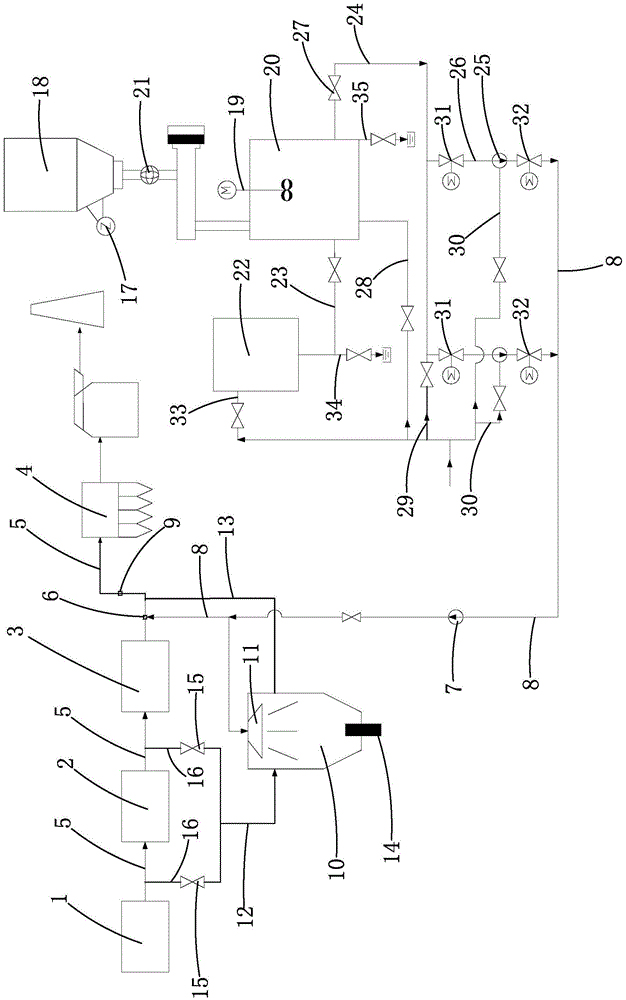

[0021] Embodiment 1: The removal efficiency monitoring mechanism includes an inductor 9 arranged in the tail gas pipeline 5 between the nozzle 6 and the electrostatic precipitator 4, and the slurry preparation mechanism obtains the halogen according to the inductor 9. parameter to adjust the lye parameters. The inductor 9 can be an inductor 9 for testing hydrogen chloride or hydrogen fluoride in the flue gas respectively, and the installation position of the inductor 9 can also be arranged in the tail gas pipeline of the electrostatic precipitator 4 and the desulfurization absorption tower, and can also monitor the flue gas The content of hydrogen chloride and hydrogen fluoride in the medium, and then obtain the data of the efficiency of the atomization injection mechanism to fix the halogen, and provide a basis for the slurry preparation mechanism to adjust the configuration parameters of the lye.

Embodiment 2

[0022] Embodiment 2: The removal efficiency monitoring mechanism includes a detection cabin 10 with a spray chamber, a nozzle 11 located on the top of the spray chamber and connected to the infusion tube 8, and the detection cabin 10 passes through a The intake pipe 12 communicating with the tail gas pipeline 5 introduces the flue gas, and the flue gas is discharged into the tail gas pipeline 5 between the air preheater 3 and the electrostatic precipitator through an exhaust pipe 13. A solid outlet 14 is provided at the bottom of the chamber, and the air inlet pipe 12 and the exhaust pipe are respectively connected to both sides of the spray chamber. By measuring and analyzing the quality and composition of the solid matter discharged from the solid outlet 14, the data on the efficiency of the atomization injection mechanism to fix the halogen is obtained, and provide a basis for the slurry preparation mechanism to adjust the configuration parameters of the lye. One end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com