Road pouring sealant with high corrosion resistance and preparation method thereof

A corrosion-resistant, potting adhesive technology, applied in the direction of adhesives, adhesive types, asphalt material adhesives, etc., can solve problems such as material corrosion, achieve extended service life, enhance adhesive performance, and reduce direct corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

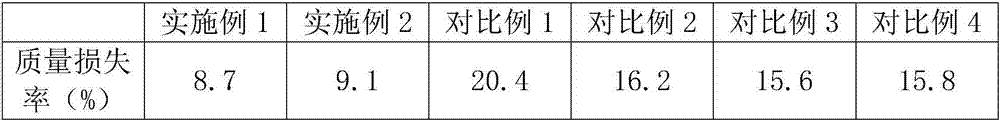

Examples

Embodiment 1

[0022] Raw material composition (parts by weight): 65 parts of No. 90 matrix asphalt, 8 parts of SBS modifier, 15 parts of waste aramid fiber, 10 parts of silicon micropowder, 6 parts of rubber powder, 12 parts of polystyrene, and 8 parts of carbon powder.

[0023] Preparation:

[0024] (1) dispense each component according to parts by weight;

[0025] (2) Raise the temperature of the asphalt to 160-170°C, stir continuously at 2000rpm, add SBS modifier to it, and stir for 40-45 minutes;

[0026] (3) Heat up to 180-190°C, add polystyrene into the system, stir for 30-40 minutes, and the rotation speed is 2000rpm;

[0027] (4) Raise the temperature to 190-200°C, add uniformly mixed silicon micropowder, rubber powder and carbon powder into the system, stir and react for 50-60 minutes, and the rotation speed is 2000rpm;

[0028] (5) Cool down to 180-190°C, add waste aramid fibers to the system, stir for 60-70 minutes at a speed of 2000rpm, and pack after cooling down to 120-130°C...

Embodiment 2

[0030] Raw material composition (parts by weight): 65 parts of No. 90 matrix asphalt, 6 parts of SBS modifier, 12 parts of waste aramid fiber, 8 parts of silicon micropowder, 5 parts of rubber powder, 10 parts of polystyrene, and 6 parts of carbon powder.

[0031] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com