Preparation method of low-temperature anti-adhesive aircraft de-icing and anti-icing liquid

An anti-icing liquid and anti-sticking technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of short duration of effect, thickening and sedimentation, large consumption, etc., and achieve the effect of reducing freezing point.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

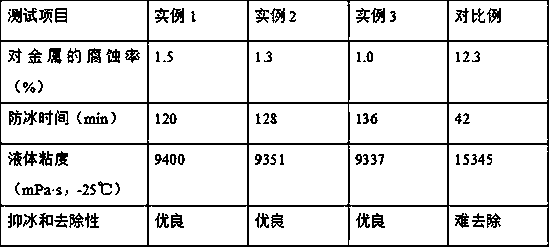

Examples

example 1

[0027] Weigh 600g of potatoes, put them into a stone mill and grind for 3 hours to obtain potato residues, put the potato residues into a plastic basin, add 1000mL of water and 500mL of sodium hydroxide solution with a mass fraction of 8% to the plastic basin, and heat at 90°C After stirring for 2 hours under the same conditions, the potato slurry was obtained, and the potato slurry was placed in a centrifugal disperser, centrifuged at a speed of 4000r / min for 10 minutes, and the supernatant was removed to obtain the lower filter residue; the above filter residue was placed in a beaker, and deionized water After washing the filter residue 3 times, add 200mL of sodium chlorite solution with a mass fraction of 20g / mL to the beaker, adjust the pH to 4.8 with a glacial acetic acid solution with a mass fraction of 90%, heat the beaker to 70°C, and keep it warm. After 2 hours, delignified fibers were obtained, and the delignified fibers were mixed with hydrochloric acid with a mass f...

example 2

[0029] Weigh 650g of potatoes, put them into a stone mill and grind them for 3.5h to obtain potato residues, put the potato residues into a plastic basin, add 1100mL of water and 600mL of 8% sodium hydroxide solution into the plastic basin, and set the temperature at 95 After stirring for 2.5 hours under the condition of ℃, the potato slurry was obtained, and the potato slurry was placed in a centrifugal disperser, centrifuged at a speed of 4500r / min for 13min, and the supernatant was removed to obtain the filter residue of the lower layer; the above filter residue was placed in a beaker and used to After washing the filter residue with ion water for 4 times, add 250 mL of sodium chlorite solution with a mass fraction of 24 g / mL to the beaker, adjust the pH to 5.0 with a glacial acetic acid solution with a mass fraction of 90%, and heat the beaker to 75 °C. After 2.5 hours of heat preservation treatment, delignified fibers are obtained. Mix the delignified fibers with hydrochlo...

example 3

[0031] Weigh 700g of potatoes, put them into a stone mill and grind them for 4 hours to obtain potato residues, put the potato residues into a plastic basin, add 1200mL of water and 700mL of 8% sodium hydroxide solution into the plastic basin, and heat at 100°C After stirring for 3 hours under the same conditions, the potato slurry was obtained, and the potato slurry was placed in a centrifugal disperser, centrifuged at a speed of 5000r / min for 15min, and the supernatant was removed to obtain the lower filter residue; the above filter residue was placed in a beaker, and deionized water After washing the filter residue 5 times, add 300mL of sodium chlorite solution with a mass fraction of 25g / mL to the beaker, adjust the pH to 5.2 with a glacial acetic acid solution with a mass fraction of 90%, heat the beaker to 80°C, and keep it warm. After 3 hours, delignified fibers were obtained, and the delignified fibers were mixed with hydrochloric acid with a mass fraction of 10% in a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com